Beneath Nigeria's vast lands lie abundant mineral resources: from limestone and granite used in construction, to lead, zinc, and barite essential for industry, and even precious gold ore. However, transforming the raw ore into high-value-added powder is a crucial step in determining the final profit. For many small and medium-sized mine owners and startups, large, expensive crushing production lines are out of reach.

This is where small hammer mills and grinders come in, becoming the ideal bridge between raw ore and wealth. With their unique advantages, they are quietly changing the landscape of mineral processing in Nigeria.

Why are small hammer mills the ideal choice for Nigerian mine owners?

Hammer mills are renowned for their versatility and powerful crushing force, making them particularly suitable for the current state of Nigeria's mining industry:

1. Powerful crushing capacity, handling perse materials:

◦ Whether it's medium-hard limestone and gypsum, or coal and ore with a certain degree of toughness, hammer mills can handle them effectively. Its high-speed rotating hammers crush materials through impact, making it ideal for primary and secondary crushing of common non-metallic and some metallic ores in Nigeria.

2. Flexible and Adjustable Output Particle Size:

◦ The particle size of the final product can be easily controlled by adjusting the aperture of the bottom screen plate. Need coarse particles for building aggregates or fine powder for further processing? One hammer crusher can meet multiple needs.

3. Simple Structure, Convenient Operation and Maintenance:

◦ This is crucial in areas with unstable power supply or a shortage of professional maintenance personnel. The simple structure means a low failure rate, and even when maintenance is needed, parts are easy to replace, minimizing downtime.

4. Low Investment Cost, Quick Return:

◦ Compared to large equipment such as jaw crushers and cone crushers, the purchase cost of a small hammer crusher is much lower, greatly reducing the financial pressure on small and medium-sized investors, allowing for rapid production and profitability.

After Crushing: How Does the Grinding Mill Achieve Value Multiplication?

Hammer mills typically crush materials to a particle size of a few millimeters to tens of mesh. However, if your goal is to produce higher-value ultrafine powders (such as mineral powders above 200 mesh), then a grinding mill is essential.

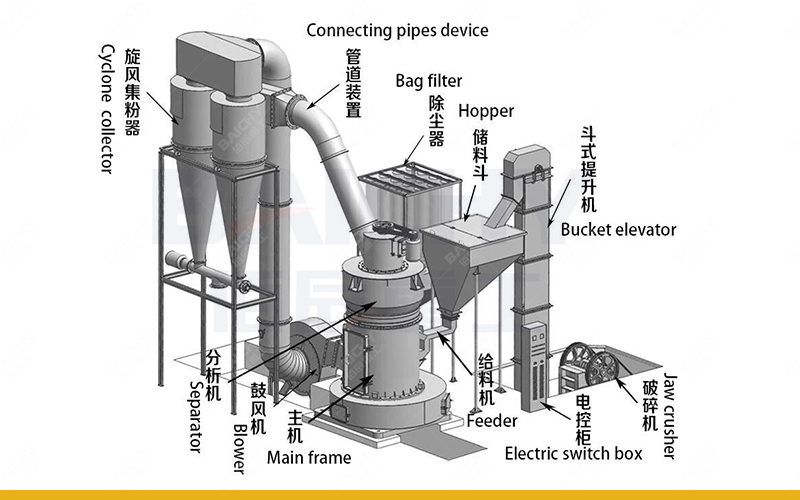

• Raymond mill (suspension roller mill): Suitable for minerals with a Mohs hardness of 7 or lower, such as limestone, calcite, and barite. The finished particle size is adjustable between 80-325 mesh, with stable output, making it a popular choice for processing mineral powders.

• Ball mill: Offers even finer grinding, up to 1000 mesh or more, suitable for fields with extremely high fineness requirements, such as ceramics and coatings industries. Although the investment and energy consumption are relatively higher, the added value of the product is also higher.

Recommended combination: The ideal process is "hammer mill + grinding mill". First, use the hammer mill for efficient coarse crushing, then feed the uniform particles into the grinding mill for fine processing. This combination significantly improves grinding efficiency and reduces overall energy consumption.

Practical Considerations for the Nigerian Market

When selecting and using this equipment in Nigeria, the following points are crucial:

1. Flexibility of Power Source:

◦ Electric Motor Drive: Preferred in urban areas with stable power supply, such as Lagos and Port Harcourt, offering low operating costs.

◦ Diesel Engine Drive: For remote areas or mines with unreliable power supply, mobile crushing and grinding units equipped with diesel engines are the perfect solution, ensuring autonomy and continuity of production.

2. Quality of Wear-Resistant Parts (Hammers, Liners):

◦ Local Nigerian minerals may vary in hardness, causing significant wear on equipment. It is essential to choose wear parts made of wear-resistant materials such as high-manganese steel or alloy steel. Although the unit price is slightly higher, the longer service life results in a lower overall cost.

3. Supplier Selection and After-Sales Service:

◦ Localized service is key. Prioritize suppliers with warehouses or service points in Nigeria (such as Lagos and Kano). This ensures quick access to spare parts and technical support, avoiding significant losses due to equipment downtime.

◦ Before purchasing, confirm that the supplier can provide installation guidance, operation training, and maintenance manuals.

4. Safety and Environmental Protection:

◦ When operating the crusher, always wear protective glasses and a mask to prevent injury from dust and debris.

◦ Consider configuring a simple bag filter to reduce dust pollution. This is not only responsible for workers but also meets increasingly stringent environmental requirements.

Success Story: From Mine Owner to Entrepreneur

Imagine you own a limestone mine. Previously, you sold raw stone directly with meager profits. After investing in a small diesel-powered hammer crusher and a Raymond mill, you can process limestone into:

• Construction crushed stone of various particle sizes

• Limestone powder for animal feed

• High-purity filler for the coatings and plastics industries

Your product line expands, your customer base extends from builders to chemical plants and feed mills, and your revenue streams persify. You are no longer just a mine owner, but an entrepreneur in the mineral processing industry.

In Nigeria's booming economy, mining presents both opportunities and challenges. Small hammer mills and grinders, with their excellent applicability and economy, offer small and medium-sized mines the possibility of achieving great results with small investments.