In the field of mining crushing, achieving efficient medium and fine crushing of materials while ensuring excellent finished product particle shape and controllable operating costs is a key focus for many mining companies. As a manufacturer of mining crushing equipment with 20 years of professional experience, we have cultivated a global market presence and launched high-performance two-stage impact crushers to meet the needs of different crushing scenarios, providing reliable, comprehensive solutions for mining crushing.

Two-stage impact crusher

The two-stage impact crusher is a high-efficiency crushing equipment optimized and upgraded from the traditional impact crusher. It is mainly used for secondary medium and fine crushing operations in industries such as mining, building materials, and metallurgy. It uses a high-speed rotating rotor to impact and crush materials, causing them to collide and pulverize within the crushing chamber, ultimately forming a finished product with uniform particle size and excellent cubic shape. This equipment is particularly suitable for crushing materials with medium to low hardness, such as limestone, dolomite, and coal gangue, and is a crucial piece of equipment in a mining crushing production line.

| Key Words | Secondary Impact Crusher |

|---|---|

| Product Model | PF Impact Crusher |

| Feed Size | ≤700mm |

| Motor Power | 45-355kw |

| Capacity | 15-800t/h |

| Core Design | The heavy-duty rotor has high inertia, enabling it to crush harder materials and operate more smoothly. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

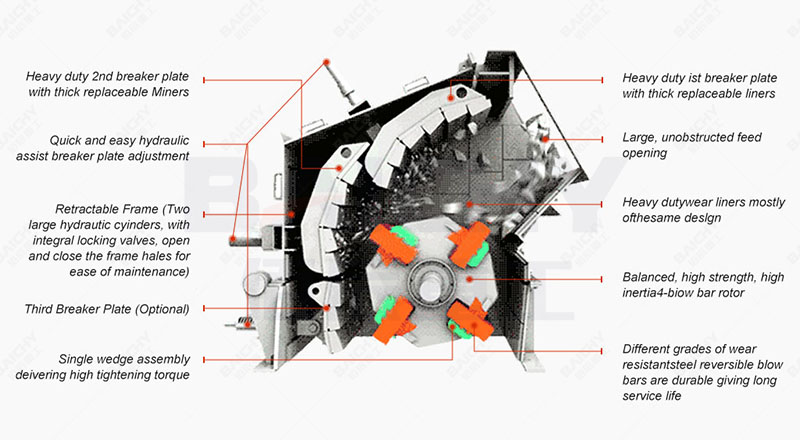

PF Impact Crusher Structure Diagram

Core Advantages

1. High Efficiency and Energy Saving, Outstanding Output

Utilizing a deep-cavity rotor design and optimized crushing process, the crushing ratio is large, processing capacity is strong, and unit energy consumption is reduced by approximately 15-20%, significantly improving the overall efficiency of the production line.

2. Excellent Particle Shape, High Finished Product Value

The crushed material particles are predominantly cubic in shape, with low needle-like and flaky content, improving the compressive strength and bulk density of the finished aggregate, making it more appealing to the high-end building materials market.

3. Wear-Resistant and Durable, Easy Maintenance

Key components are made of high-chromium alloy wear-resistant materials, offering strong impact resistance and a long service life. The hydraulic opening device makes replacement of vulnerable parts more convenient and quick, reducing downtime.

4. Intelligent Control, Stable Operation

An optional intelligent monitoring system can monitor bearing temperature, vibration, and other parameters in real time, enabling fault warnings and remote adjustment to ensure long-term stable operation of the equipment.

5. Environmentally Friendly and Low-Noise, Green Production

The sealed structure design effectively suppresses dust leakage, and combined with noise reduction technology, the operating noise is low, meeting stringent environmental protection production requirements.

Typical Application Scenarios

• Sand and Gravel Aggregate Production Line: Used for secondary crushing of materials such as limestone and river pebbles to produce high-quality manufactured sand and various sizes of aggregates.

• Mining and Metallurgical Crushing: Suitable for medium and fine crushing of medium- and low-hardness ores such as iron ore, copper ore, and gold ore.

• Construction Waste Recycling: Crushing of demolition concrete, bricks, and tiles to produce recycled aggregates.

• Cement Production Pretreatment: Used for secondary crushing of limestone and marl to provide materials of suitable particle size for raw meal preparation.

PF Impact Crusher Crushing Site

Successful Project Cases

Case 1: Vietnam Limestone Crushing Project

The client was a large local building materials company. Their original production line had low crushing efficiency and produced mostly flaky finished products. We installed two two-stage impact crushers to replace the old equipment. After the upgrade, the production line's hourly output increased by 30%, the particle shape of the finished aggregate was significantly improved, and the content of needle-like and flaky particles was less than 8%, greatly enhancing the client's product competitiveness.

Case Study 2: Shanxi Coal Mine Gangue Comprehensive Utilization Project

Addressing the characteristics of uneven hardness and large variations in moisture content in coal mine gangue, we provided a customized two-stage impact crusher solution, featuring enhanced wear-resistant design and anti-clogging material structure. In the two years since its operation, the equipment has achieved an average mean time between failures (MTBF) of over 2000 hours, helping the client transform gangue into high-quality roadbed material, achieving a win-win situation for resource utilization and environmental protection.

Frequently Asked Questions (FAQ)

Q1: Is a two-stage impact crusher suitable for crushing high-hardness materials such as granite?

A: This equipment is mainly suitable for materials with medium hardness and below, with a compressive strength not exceeding 350MPa. For high-hardness materials such as granite and basalt, we recommend using a cone crusher based on the lamination principle as the secondary crushing equipment.

Q2: What is the typical equipment maintenance cycle?

A: Under normal circumstances, the service life of the rotor wear parts is approximately 3-6 months (depending on material hardness and output). We recommend routine inspections every shift and a comprehensive overhaul and maintenance every six months. We provide detailed maintenance plans and training support.

Q3: Can you customize the equipment to suit our site conditions?

A: Yes. We offer non-standard customization services, including inlet/outlet direction, motor arrangement, and overall size adjustments, ensuring the equipment fits your production line layout and space constraints.

Q4: What specific environmental protection measures are in place?

A: The equipment adopts a multi-layer sealing and negative pressure dustproof design, which can effectively control dust. It can also be equipped with our dust removal system and soundproof enclosure, ensuring the entire line meets domestic and international environmental standards.