The rotary drum dryer is a highly efficient continuous drying equipment widely used in the chemical, food, mineral, building materials and other industries. Through the rotation of the rotary drum, the wet material is constantly turned in the drum and fully contacted with the hot air, thereby achieving a fast and uniform drying effect. This drying equipment has become an indispensable drying solution in industrial production due to its large processing capacity, simple operation and strong adaptability.

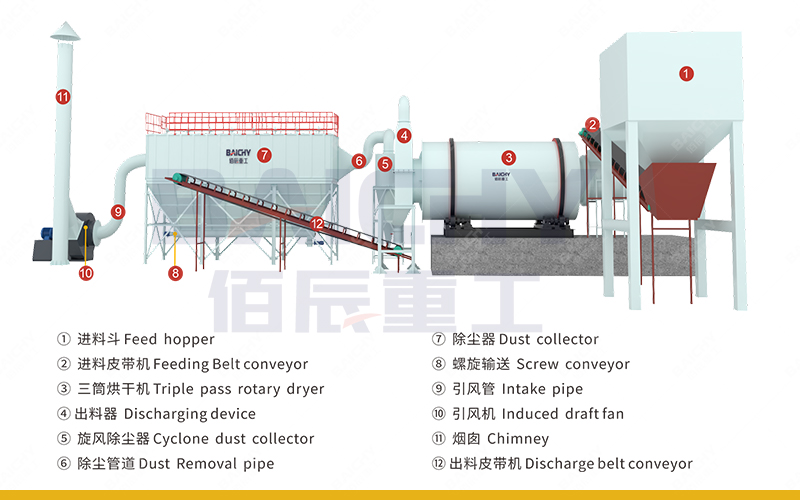

The main structural components of the rotary drum dryer

1. Rotating drum system

Drum: Made of high-quality stainless steel or carbon steel, the diameter is usually 0.5-4.5 meters and the length can reach 20 meters

Support device: including support wheels, retaining wheels and bearings to ensure the smooth rotation of the drum

Transmission system: composed of motors, reducers, gears, etc., driving the drum to rotate at a speed of 2-10rpm

2. Hot air system

Hot air furnace: Provides the heat source required for drying, which can be heated by coal, gas, oil or electricity

Blower: Force hot air flow to improve drying efficiency

Duct system: Reasonably arranged hot air ducts to ensure uniform heat distribution

3. Feeding and discharging devices

Feeding screw: Evenly and continuously feeds wet materials into the drying drum

Discharging device: Including discharging screw and collecting hopper to ensure smooth discharge of materials after drying

4. Auxiliary device

Dust removal system: collect dust generated during drying

Control system: PLC automatic control system to achieve precise adjustment of parameters such as temperature and speed

Working principle of rotary drum dryer

1. Basic working process

Wet materials enter the rotary drum continuously and evenly through the feeding device

The hot air (100-800℃) generated by the hot air furnace flows in the opposite or same direction as the materials

The drum rotates at a certain inclination (3-5°) and speed, so that the materials are constantly flipped and moved forward

The materials are fully in contact with the hot air during the movement, and the moisture gradually evaporates

The dried materials are discharged from the discharge end, and the exhaust gas is discharged after dust removal

2. Heat exchange mechanism

Conduction heat transfer: direct contact heat transfer between the material and the inner wall of the drum

Convection heat transfer: convection heat exchange between hot air and the surface of the material

Radiation heat transfer: radiation heat transfer between the high-temperature drum and the hot air

3. Material movement characteristics

Lifting-scattering stage: The lifting plate in the drum lifts the material to a certain height and then sprinkles it

Sliding stage: The material falls in a waterfall-like manner under the action of gravity

Forward movement: The drum tilts and rotates to make the material move continuously to the discharge end

Key technical parameters of rotary drum dryer

| Parameter name | Typical range | Influencing factors |

| Drum speed | 2- 10 rpm | Material characteristics, drying requirements |

| Hot air temperature | 100-800℃ | Material temperature resistance, moisture content |

| Residence time | 5-90 minutes | Drum length, speed, inclination |

| Evaporation intensity | 10-80kg water/m³·h | Hot air temperature, wind speed |

| Thermal efficiency | 50-75% | System insulation, waste gas recovery |

Selection guide for rotary drum dryer

1. Material characteristics analysis: including initial moisture content, final moisture content, particle size, thermal sensitivity, etc.

2. Production requirements: Determine equipment specifications based on hourly or daily processing volume

3. Heat source selection: Consider local energy supply and operating costs

4. Installation conditions: site size, power configuration, environmental protection requirements, etc.

5. Budget control: Optimize investment costs while meeting process requirements

As a mature and reliable drying equipment, the rotary drum dryer plays an increasingly important role in industrial production through continuous technological innovation and optimization. Understanding its working principle and system composition will help users select, use, and maintain the equipment correctly, so as to obtain the best drying effect and economic benefits. With the deepening of intelligent manufacturing and green manufacturing concepts, rotary drum drying technology will surely usher in a broader development space.