The impact crusher is displayed in the workshop

Recently, exciting news arrived from overseas: the PF1007 impact crusher for construction waste has been successfully installed and commissioned in Russia. This is not just a simple equipment export; it's a transnational validation of our company's 20 years of professional expertise and technological innovation. Russia, located in a high-latitude region, is experiencing rapid infrastructure development, and the demand for construction waste recycling is urgent. The successful implementation of this project precisely meets the local market needs, providing a reliable Chinese solution to the challenges of construction waste management, and laying a solid foundation for our further expansion into the Russian-speaking and Eastern European markets.

| Key Words | Construction Waste Crusher |

|---|---|

| Product Model | Impact Crusher |

| Feed Size | ≤250mm |

| Motor Power | 37-55kw |

| Capacity | 15-60 t/h |

| Core Advantages | High efficiency and energy saving, excellent particle shape, flexible adjustment, and simultaneous shaping capabilities. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Equipment Overview: PF1007 Impact Crusher

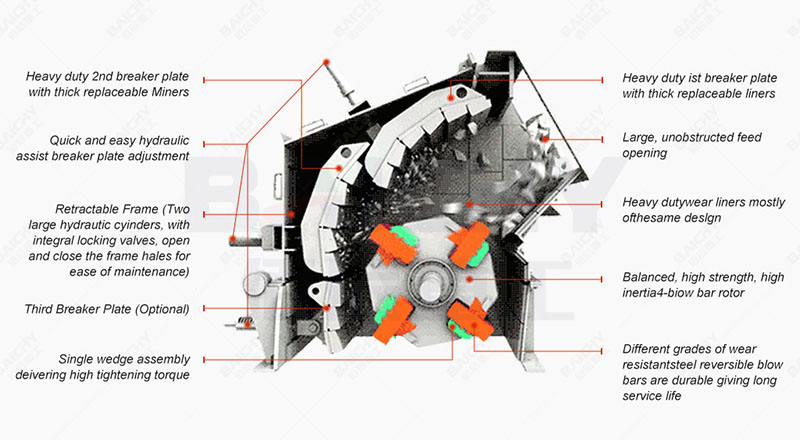

The PF1007 impact crusher is a key member of our flagship product line, specifically designed for crushing medium-hard materials, especially suitable for processing construction waste, concrete, and asphalt blocks. This model utilizes a mature impact crushing principle, where a high-speed rotating rotor throws the material against an impact plate, resulting in repeated impacts and crushing. It features excellent product particle shape, fewer irregular edges, and a reasonable particle size distribution, making it an ideal device for producing high-quality recycled aggregates.

PF Impact Crusher Structure Diagram

Core Advantages: Why Choose Our PF1007?

With 20 years of R&D and manufacturing experience, we have endowed the PF1007 crusher with multiple competitive advantages:

1. High Efficiency and Energy Saving, Strong Processing Capacity: The optimized crushing chamber and rotor design result in high material throughput, low energy consumption, and outstanding single-machine processing capacity, effectively reducing customer operating costs.

2. Excellent Product Particle Shape: The impact crushing principle ensures that the output is mostly cubic, with low needle-like and flaky content. The produced recycled aggregates have high strength and can be directly used for road base layers, brick making, etc., resulting in high added value.

3. Handles Complex Materials: Specially optimized anti-iron capabilities and anti-clogging design allow it to better handle construction waste containing impurities such as rebar and wood, ensuring strong adaptability and stable operation.

4. Robust Structure and Easy Maintenance: Key components are made of high-strength materials and wear-resistant processes, ensuring a long service life. The machine features a compact structure, and the important maintenance doors are designed for user-friendliness, making daily maintenance and replacement of wear parts convenient and quick.

5. Environmental Design: It can be equipped with dust removal and noise reduction devices, effectively controlling dust and noise during the production process and meeting strict environmental requirements.

PF impact crusher crushing site

Success Story: In-depth Analysis of the Russian Project

This Russian project is located in a major city in western Russia. The client is primarily engaged in urban renovation and demolition projects, generating a large amount of construction waste daily. Previously, they used landfill methods, which were costly and environmentally unfriendly. After extensive research, they finally selected our PF1007 impact crusher for construction waste.

Client Needs: To find a mobile, efficient, and high-quality on-site construction waste processing solution.

Solution: We configured a mobile crushing plant for the client, with the PF1007 as the main machine. After the equipment arrived on-site, our engineers conducted rapid installation, commissioning, and technical training.

Operating Results: The equipment is currently operating stably, processing 80-120 tons of construction waste per hour. The finished aggregate particle size is adjustable between 0-40mm, fully meeting the client's needs for road base material and commercial concrete mixing plants. The client highly praised the equipment's output particle shape and the reliability of continuous operation.

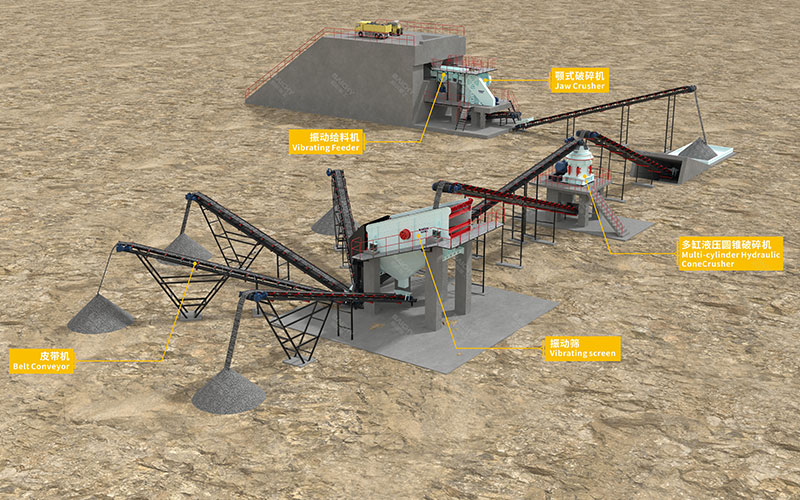

Impact crushing production line

Related Equipment Recommendations

For the entire process of construction waste resource utilization, we can provide a one-stop solution. Key equipment配套 with the PF1007 includes:

Feeding Equipment: ZSW series vibrating feeder, ensuring uniform feeding and guaranteeing efficient, full-load operation of the crusher.

Screening Equipment: YK series circular vibrating screen, for precise classification of crushed materials to obtain various specifications of finished products.

Mobile Solution: Wheel-mounted or crawler-mounted mobile crushing plant, integrating feeding, crushing, and screening, offering flexible relocation, especially suitable for demolition site operations.

Iron Removal Equipment: RCYD series self-discharging magnetic separator, effectively separating rebar and wire from the material, protecting downstream equipment.

Frequently Asked Questions (FAQ)

Q1: Is the PF1007 suitable for processing wet and sticky construction waste?

A1: The PF1007 has certain requirements regarding the moisture content of the material. For materials that are too wet or sticky, we recommend pre-drying or using pre-treatment equipment (such as a trommel screen). You can also contact us for customized solutions.

Q2: What is the service life of wear parts (such as hammer plates)? Is replacement easy?

A2: The service life of wear parts is closely related to the hardness and abrasiveness of the processed materials. When processing ordinary construction waste, the service life of the hammer plates is usually several hundred hours or more. The equipment is designed for easy maintenance, and replacement can be done quickly using special tools.

Q3: Can you provide design and installation guidance for the entire production line?

A3: Absolutely. As a manufacturer with 20 years of experience, we can not only provide inpidual machines but also offer complete solutions, from process design and equipment selection to installation guidance and commissioning training, based on your site conditions, raw material characteristics, and finished product requirements.

Q4: Does the equipment comply with international standards such as EU CE certification?

A4: Yes. Our core product series, including the PF1007, are designed and manufactured in accordance with international standards and can obtain CE certification, ensuring the safety and environmental friendliness of the equipment and meeting the access requirements for markets such as Russia, Central Asia, and Europe.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.