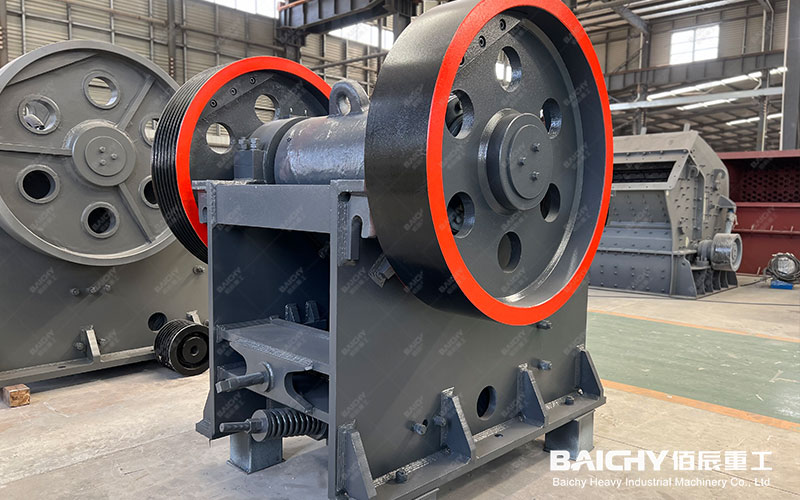

In numerous fields such as mining, building materials, and water conservancy, the PE600x900 (also known as 900x600) jaw crusher, with its robust structure, reliable performance, and wide applicability, is hailed as the backbone of primary crushing. As the manager or owner of such equipment, you surely understand that the long-term profitability of equipment depends not only on its initial investment but also on its operating and maintenance costs throughout its entire lifecycle. Among these, the management and replacement of wear parts is a core element in controlling costs and ensuring continuous and stable production.

PE Jaw Crusher PDF,Download ↓↓↓

As a marketing expert with many years of experience in the mining equipment industry, after communicating with countless clients, I have found that those with the highest operational efficiency are invariably experts in wear parts management. They not only know what needs to be replaced but also when to replace it, how to choose the right parts, and how to plan ahead. Today, we will present you with a detailed list of wear parts and scientific management strategies for the PE600x900 jaw crusher.

I. Detailed Explanation of the Core Wear Parts List for the PE600x900 Jaw Crusher

Know yourself and know your enemy, and you will never be defeated. First, let's clearly understand the key consumable components of the PE600x900 jaw crusher:

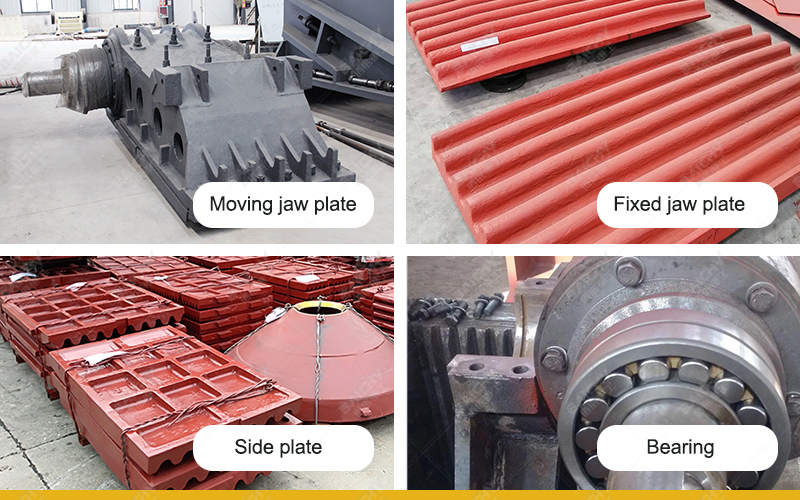

1. Jaw Plate (Tooth Plate): The teeth of the crusher, directly in contact with the material and bearing the greatest impact and wear. They are usually pided into fixed jaw plates and movable jaw plates.

◦ Material: Usually high manganese steel (ZGMn13), which has the characteristic of surface hardening under high impact and becoming harder with wear. For different materials (such as granite, basalt, or limestone), ultra-high manganese steel or composite alloy materials can also be selected.

◦ Factors affecting lifespan: Material hardness, particle size, moisture content, feeding method, crushing ratio, etc.

2. Side Guard Plates: Installed on both sides of the crushing chamber to protect the frame from wear. Their wear rate is usually slower than that of the jaw plates.

◦ Function: They are the guardians of the frame; replacing side guard plates is far less costly than repairing or replacing the frame.

3. Thrust Plate (Toggle Plate): It is not only a force transmission component but also plays a crucial role as an overload protection device. When uncrushable objects (such as iron blocks) enter the crushing chamber, the thrust plate will break first, protecting core components such as the main shaft and bearings from catastrophic damage.

◦ Note: It is strictly forbidden to use ordinary cast iron parts to replace the thrust plate specified in the design; otherwise, the overload protection function will be lost.

4. Springs, tie rods, and tie rod nuts: These components together form the adjustment and reset mechanism, used to maintain the working position of the movable jaw and provide reset force during retraction.

II. Beyond the Catalog: Scientific Management Strategies to Extend the Lifespan of Your Equipment

Simply knowing which parts are vulnerable is far from enough. Excellent managers will adopt the following strategies:

• Regular Inspection and Recording: Establish a vulnerable parts inspection file, regularly measure the wear of the jaw plates, and record the tonnage crushed for each set of vulnerable parts. This helps you accurately predict replacement time and avoid sudden downtime.

• Timely Rotation: When the bottom of the jaw plate is more severely worn than the top, it can be rotated vertically for use, effectively extending its service life by 20%-30% and significantly reducing the cost per ton. • Original Parts & Quality Certification: Choosing original parts or parts with rigorous quality certification is crucial. Inferior parts not only have a short lifespan but may also cause abnormal wear and even damage the main equipment structure, resulting in a serious penny wise, pound foolish outcome.

• Reasonable Inventory Planning: Develop a scientific safety stock plan based on your production schedule and the lifespan of wear parts. Ensure that critical wear parts (such as jaw plates and thrust plates) have spare stock to cope with emergencies, while avoiding excessive capital tied up.

III. Choose Us for One-Stop Solutions

We understand that you need more than just a single parts supply. As a professional mining equipment solutions provider, we offer:

• A Full Range of High-Quality Wear Parts: Utilizing advanced processes and superior materials, we ensure wear resistance and service life, providing quantifiable cost advantages per ton.

• Professional Technical Support: Our team of engineers can provide you with wear part diagnosis, replacement guidance, and optimization suggestions to help you develop the best maintenance plan.

• Rapid supply system: A well-established warehousing and logistics network ensures that you can obtain the necessary spare parts in a timely manner when needed, minimizing downtime losses.