Mobile Rock Gold Plant | Small Gold Processing Plant

In the gold mining sector, especially for dispersed deposits, varying ore body sizes, or remote locations, traditional large-scale fixed processing plants often involve huge investments, long construction periods, and lack flexibility.

The mobile rock gold processing plant, also known as a small-scale gold processing plant, has emerged as an innovative, efficient, and economical solution in modern mining.

A mobile rock gold processing plant is a modular, movable gold processing system that integrates crushing, screening, grinding, separation (such as gravity separation, flotation, etc.), and even concentration and dewatering processes. It is specifically designed for processing rock gold ore, with the core objective of immediate processing at or near the mine site, significantly reducing ore transportation costs and quickly verifying the economic viability of the deposit.

Compared to large fixed plants, the core features of this small-scale gold processing plant are its mobility and modularity. All major equipment is typically installed on container frames or heavy-duty trailers, allowing for road transport and quick installation and commissioning. This is particularly attractive for late-stage exploration, small mines, tailings reprocessing, or projects in complex terrain. With two decades of technological experience, we ensure that each mobile module is robust and reliable, with smooth process integration and stable recovery rates.

Mobile Rock Gold Plant | Small Gold Processing Plant

Why choose a mobile solution?

1. Low investment threshold and rapid startup: No need to build permanent plant buildings and infrastructure; capital investment is significantly lower than for fixed plants. Equipment can be operational within days or weeks after delivery, accelerating cash flow.

2. Excellent flexibility and adaptability: Easily transferable to different mine sites, following the mining face to maximize resource utilization. Particularly suitable for multiple dispersed small ore bodies or phased mining projects.

3. Significantly reduced transportation costs: Processing ore directly at the mine site allows for the transportation of high-grade gold concentrate or bullion, rather than large quantities of raw ore, resulting in significant savings in logistics costs.

4. Environmentally friendly and small footprint: The modular design reduces permanent land occupation and damage. Advanced environmental designs (such as circulating water systems and dust control) are easily integrated.

5. Controllable Risk: Allows investors to test the economic value of the deposit with a smaller initial investment, reducing investment risk before large-scale plant construction.

6. Mature Technology, Guaranteed Recovery Rate: Integrates twenty years of proven mining crushing equipment (such as jaw crushers and cone crushers) and efficient beneficiation processes (such as centrifuges, shaking tables, and flotation machines) to ensure gold recovery rates.

Success Story Snapshot

In a project in West Africa, we configured a 50-ton per day mobile gold processing plant for a client. The mine site was scattered and lacked stable power. Our solution included:

- Mobile Crushing and Screening Module: Using diesel-driven jaw crushers and cone crushers.

- Mobile Grinding and Gravity Separation Module: Ball mill combined with Nelson centrifuges and shaking tables for efficient recovery of free coarse gold.

- Mobile Power Module: Integrated diesel generator set.

The entire plant was deployed and commissioned on-site within 3 weeks. After commissioning, the total gold recovery rate reached over 85%, and the client recovered their equipment investment costs in just 6 months, fully demonstrating the efficiency and economics of a small-scale gold processing plant.

Recommended Equipment

Choosing the core equipment is crucial for building an efficient mobile beneficiation plant. Based on our manufacturing experience, we recommend the following key units:

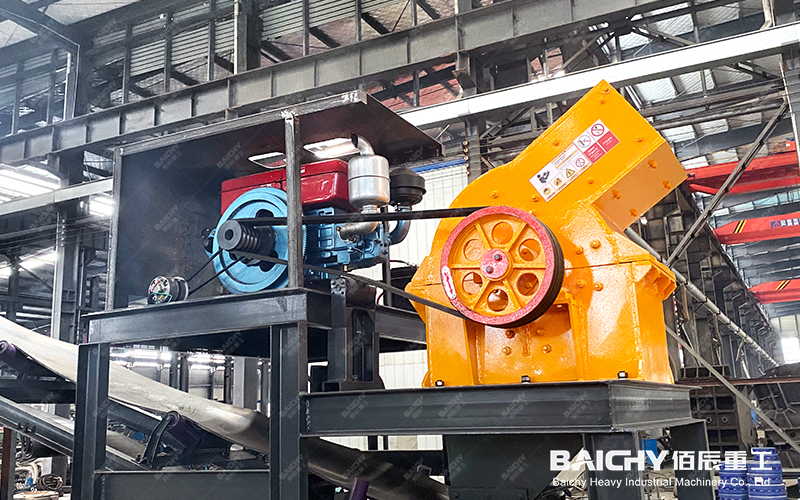

- Feeding and Primary Crushing Unit: Mobile jaw crushing station, for processing large lumps of raw ore, robust and durable.

- Secondary and Tertiary Crushing and Screening Unit: Mobile cone crusher paired with a multi-layer vibrating screen to achieve closed-circuit crushing and control the particle size entering the mill.

- Grinding and Separation Unit: Mobile ball mill or wet grinding mill, paired with centrifugal gold concentrators, jigs, or small flotation columns.

- Auxiliary Systems: Mobile diesel generator set, water pump station, and automated control container.

Frequently Asked Questions (FAQ)

Q1: What is the processing capacity range of a mobile beneficiation plant?

A1: Typically, daily processing capacity ranges from 10 to 300 tons, with 20-100 tons/day being the most common range for small-scale gold processing plants, and can be customized based on ore characteristics and production requirements.

Q2: Is it suitable for all types of gold ore?

A2: It is mainly designed for hard rock gold (vein gold) ore. For placer gold deposits, mobile washing and screening equipment is usually used. The process route (all-gravity separation, gravity separation + flotation, all-slime cyanidation, etc.) needs to be determined based on the ore's process mineralogy analysis.

Q3: What is the level of automation? How many people are needed for operation?

A3: Control systems can be configured from basic manual to highly automated. A standard 50-ton/day mobile hard rock gold processing plant typically requires 3-5 operators.

Q4: How long does it take to relocate and install the equipment?

A4: This depends on the size of the plant and the number of modules. For a medium-sized plant, dismantling and transportation may take 1-2 weeks, and installation and commissioning at the new location may take 1-3 weeks, which is much faster than building a fixed plant.

Q5: As a manufacturer with 20 years of experience, what support do you provide?

A5: We provide turnkey solutions from single mining crushing equipment units to complete mobile hard rock gold processing plants, including process design, equipment manufacturing, installation guidance, operation training, and long-term spare parts supply and technical support.

In today's pursuit of efficiency and cost control, mobile hard rock gold processing plants represent an important trend in the gold mining industry towards flexibility and lean operations. It is not only an ideal choice for prospectors and small and medium-sized mines, but also provides an excellent tool for large mining companies to process marginal resources or conduct pilot projects. With our twenty years of experience and technological expertise in the field of mining crushing equipment, we are confident in providing our customers with personalized small-scale gold processing plant solutions that offer stable performance, high recovery rates, and a quick return on investment, helping you succeed in your gold mining endeavors.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.