Mobile Jaw Crusher Explained

In numerous fields such as mining, construction waste processing, and road construction, primary crushing of materials is a crucial step in the production process. Mobile jaw crushers, with their exceptional flexibility and powerful crushing capabilities, are becoming a core piece of equipment for many projects seeking efficient and low-cost operations. As a manufacturer of mobile crushing equipment with 20 years of experience, we will provide you with an in-depth analysis of this revolutionary equipment.

| Product Model | Mobile Jaw Crusher |

|---|---|

| Feed Size | 0-800mm |

| Motor Power | 100-500kw |

| Capacity | 30-800 t/h |

| Core Equipment | PE Jaw Crusher |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

I. What is a Mobile Jaw Crusher?

A mobile jaw crusher is essentially a traditional fixed jaw crusher, feeder, vibrating screen, and conveyor system integrated onto a dedicated mobile chassis. It breaks away from the reliance of fixed production lines on specific locations, fundamentally shifting from transporting materials to the production line to moving the production line to the material pile. Its core advantages lie in its integrated unit design and excellent mobility, allowing for rapid relocation as the work site changes, significantly saving on material transportation costs and infrastructure construction time.

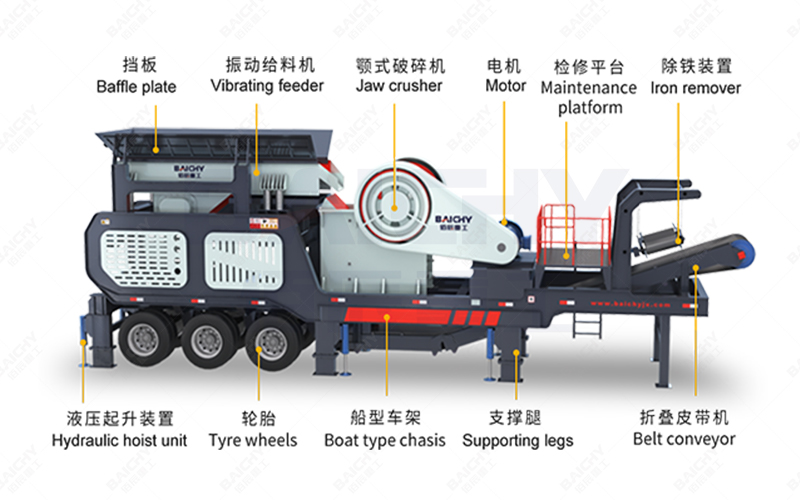

Structure diagram of a mobile jaw crusher

II. Core Structure and Working Principle

An efficient mobile jaw crusher mainly consists of the following major systems:

1. Feeding System: Typically includes a vibrating feeder and pre-screening device, used to uniformly and continuously feed material into the crushing chamber and pre-screen out soil and fine materials to improve the efficiency of the main machine.

2. Crushing Host: Uses a classic jaw crusher, consisting of a fixed jaw plate and a movable jaw plate to form the crushing chamber. The motor drives the eccentric shaft, causing the movable jaw plate to perform periodic reciprocating motion, crushing the material through compression and bending. Its robust structure is particularly suitable for processing hard, abrasive materials such as granite, basalt, and river pebbles.

3. Power System: Can be driven by a diesel engine or external power supply, providing power to the entire unit and ensuring normal operation even in remote areas without mains electricity.

4. Conveying System: Includes a discharge belt conveyor, used to transport the crushed finished material to a designated stockpile or the next stage of equipment.

5. Mobile Chassis: Uses heavy-duty truck axles and a powerful hydraulic drive system to ensure the equipment can move flexibly within the construction site and even be transported on roads.

III. Key Advantages: Why Choose a Mobile Jaw Crusher?

Based on our 20 years of manufacturing and service experience, customers choose mobile jaw crushers primarily for the following irreplaceable advantages:

• Extremely high flexibility and convenient relocation: The equipment can move independently or be towed by a trailer, allowing for quick switching between different work sites, especially suitable for urban construction waste treatment projects with dispersed workloads and limited space.

• Significantly reduced operating costs: Eliminates the huge transportation costs of materials from the mining site to a fixed production line, and avoids complex steel frame foundations and installation work, resulting in a shorter return on investment period.

• Integrated unit, ready to use: After the equipment arrives at the site, it requires almost no complex installation; it can be put into production after connecting the hydraulic support legs for leveling, truly achieving rapid commissioning.

• Adaptable to various complex working conditions: Whether in rugged mines or muddy demolition sites, its strong passability can handle the challenges, making it a true mobile crushing plant.

• Environmental protection and intelligent control: Modern models are equipped with advanced dust removal and noise reduction systems and intelligent control systems, which can monitor the operating status in real time, achieving energy saving, environmental protection, and stable production.

IV. Application Scenario Analysis

• Construction waste recycling: Directly crushing concrete and bricks at the demolition site, converting them into recycled aggregates, is the most efficient way to achieve turning waste into treasure.

• Sand and gravel aggregate production: Near mines or rivers, it can directly perform primary crushing of raw materials, forming a flexible production line.

• Road construction and maintenance: It can crush curbs and discarded asphalt materials on-site for roadbed paving, greatly saving material transportation costs.

• Small to medium-sized quarries: As the main crushing equipment, it can move with the advancement of the mining face, optimizing the mining process.

V. Key Factors in Choosing a Reliable Manufacturer

A manufacturer with 20 years of experience means a deeper understanding of equipment reliability, durability, and the challenges of actual working conditions. When choosing, please pay attention to:

• Structural design and materials: The materials and processes of core components such as the main frame and jaw plates determine the equipment's lifespan.

• Power matching and energy consumption: An efficient power system can reduce fuel or electricity consumption while ensuring output. • After-sales service and parts supply: Extensive experience means more accurate fault diagnosis and faster parts support, ensuring the continuity of your production.

In summary, a mobile jaw crusher is not just a piece of equipment, but a strategic choice that enhances project economic efficiency and production flexibility. Choosing an experienced partner will lay a solid foundation for the success of your project.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Aggregate crusher equipment

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.