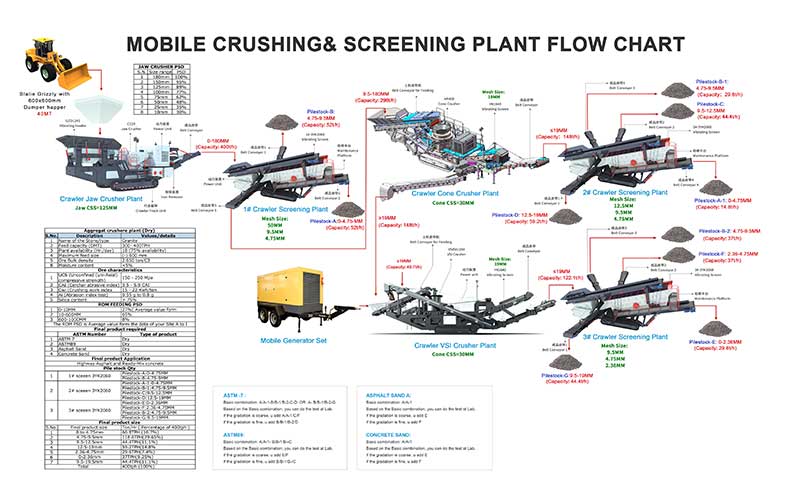

Crawler Mobile Jaw Crusher

As a leading manufacturer of track-mounted mobile crushing stations (or mobile crushers), we understand that maximizing the productivity and lifespan of your equipment hinges on two pillars: intelligent operation and rigorous safety management. This practical handbook consolidates essential knowledge for operators and site managers, ensuring your mobile crushing equipment delivers optimal performance while safeguarding personnel and assets.

I. Intelligent Control System Operation: Mastering the "Smart Brain"

Remote Monitoring & Data Acquisition

Fault Self-Diagnosis & Early Warning

Automatic Feed Regulation & Load Control

II. Relocation & Transport Safety Protocols: Ensuring Safe Movement

Self-Propelled Track Travel (Walking) Precautions

-

Route Inspection: Prior to movement, inspect the ground for firmness, levelness, and allowable gradients (typically ≤25° longitudinal, ≤15° lateral). Clear sharp rocks, holes, and obstacles.

-

Secure All Components: Fully retract and lock the feeder, side conveyors, and other extensions into travel position.

-

Low & Steady Speed: Travel at low speed (typically <1 km/h). Avoid sharp turns and rapid movement on uneven ground. For long-distance moves, trailer transport is strongly recommended.

Low-Loader (Trailer) Transport Safety Essentials

-

Proper Securing: Position the plant at the trailer's center of gravity. Chock the tracks front and rear with wedges, and securely fasten the undercarriage to the trailer using rated chains or straps to prevent any movement.

-

Check Dimensions & Weight: Verify overall transport height and width to avoid bridge/tunnel strikes. Ensure total weight does not exceed the trailer's rated capacity.

-

Legal Compliance: Obtain necessary permits for oversized loads. Use appropriate warning signs and markings during transport.

III. On-Site Operational Safety Essentials: Safety First, Production Follows

Feed Size & Uniformity Control

CSS (Closed Side Setting) Adjustment Protocol

Dust Suppression & Noise Control Measures

-

Dust Control: Ensure the water tank for the spray system is full and nozzles are unclogged, providing effective mist at feed, crush, and transfer points. Connecting to an external dust collector is optimal.

-

Noise Reduction: Operators must wear hearing protection (ear plugs or muffs). Position the plant away from sensitive areas where possible, or use acoustic barriers.

IV. Daily Maintenance & Inspection SOP: Prevention is Better Than Cure

Hydraulic System Maintenance

-

Daily: Check oil level, temperature, and for any leaks.

-

Weekly/Monthly (or by hours): Clean or replace hydraulic filters. Periodically sample oil for cleanliness and performance analysis.

-

Scheduled: Replace all hydraulic fluid per manufacturer's intervals (e.g., every 2000 operating hours).

Undercarriage (Track System) Inspection

-

Daily: Check track tension and remove any material wrapped around the tracks or rollers.

-

Every 50-100 Hours: Inspect wear on carrier rollers, idlers, and sprockets. Check the tightness of track shoe bolts.

Crushing Chamber & Wear Parts Check

-

Daily (after shutdown): Inspect jaw dies, blow bars, liners, mantles, concaves, etc., for wear and cracks.

-

Scheduled: Rotate, adjust, or replace wear parts based on wear to maintain product gradation and output. Always replace wear parts in sets (e.g., symmetrically in jaw crushers) to maintain balance.

V. Common Fault Emergency Response: Quick Action Guide

|

Fault/Symptom

|

Potential Causes

|

Immediate Actions & Solutions

|

|---|---|---|

|

Blockage (Bridging/Jamming)

|

Over-feeding, oversized material, uncrushable object, downstream blockage.

|

1. STOP the plant immediately and halt feeding.

2. Attempt to reverse the crusher (if designed for reversible operation). 3. Manually clear the obstruction from the feed hopper and chamber. 4. Check if the discharge conveyor is running freely. |

|

Overload Shutdown

|

Excessive feed, CSS too small, change in material hardness, electrical fault.

|

1. Check the fault code on the control panel.

2. Clear the crushing chamber, then reset the overload protection. 3. Check and increase the CSS if needed. 4. Restart feeding at a reduced rate. |

|

Conveyor Belt Misalignment

|

Material buildup on rollers, faulty tracking roller, improper belt splice, off-center loading.

|

1. Stop the conveyor and clean any material stuck on pulleys/rollers.

2. Adjust the snub/idler roller on the side the belt is running towards. 3. Check and correct the loading chute to ensure centered feed onto the belt. |

VI. Frequently Asked Questions (FAQ)

Q1: Does the remote monitoring function work in remote areas with poor network signal?

Q2: How often does the undercarriage (track system) need to be replaced?

Q3: What should we do if a major breakdown occurs on-site that we cannot fix?

About of Baichy Heavy Industry

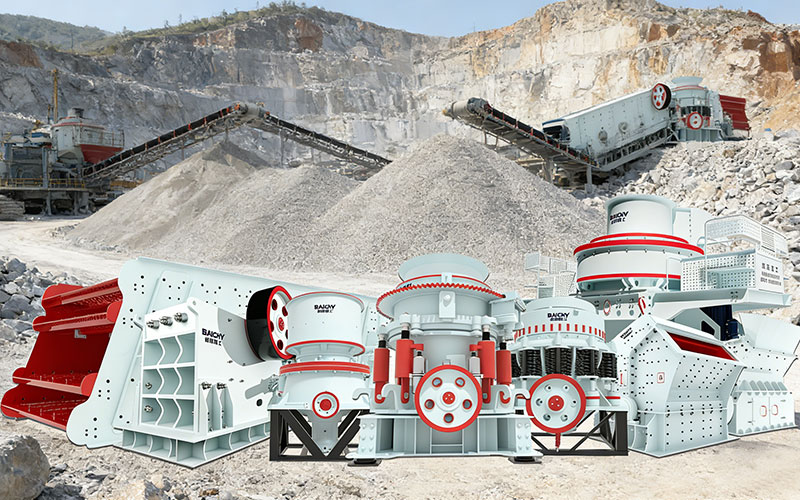

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!