Crawler Mobile Impact Crusher

As a leading manufacturer of mobile crushing equipment, we understand that today's mining and demolition contractors face two major challenges: meeting strict environmental regulations while maintaining profitability. This guide explores how modern tracked mobile crushing plants deliver both green operation and superior economic returns.

Environmental Compliance: Meeting Global Standards

Modern construction sites require equipment that meets international environmental standards. Our tracked mobile crushing plants come with integrated systems designed for regulatory compliance.

1.1 Advanced Dust Suppression Systems

Dust control remains a primary concern on crushing sites. Our plants feature intelligent spray systems with strategically placed nozzles at transfer points, crusher inlets, and screening decks. These systems use minimal water while maintaining effective dust suppression, keeping airborne particulate matter within safe limits.

1.2 Acoustic Performance Solutions

Noise reduction enclosures are engineered to lower operational decibel levels without compromising accessibility for maintenance. Customizable panels allow for different configurations based on local noise regulations and site requirements.

1.3 Water Management Systems

Closed-loop water recycling systems process wastewater from washing operations, separating solids and returning clean water to the circuit. This reduces freshwater consumption by up to 90% compared to traditional methods.

Circular Economy Applications: Turning Waste into Value

Mobile crushing technology plays a crucial role in the circular economy by transforming demolition materials into valuable products.

Case Study: Urban Demolition Project

-

Input Material: Demolition concrete from city redevelopment

-

Processing: Primary crushing with jaw crusher, secondary processing with impact crusher

-

Output: High-quality recycled aggregates meeting BS/EN standards

-

Application: Base material for road construction projects within 15-mile radius

This approach demonstrates how mobile crushing creates local supply chains while reducing landfill dependency and transportation emissions.

Operational Efficiency: Maximizing Your Investment

The true economic advantage of mobile crushing comes from operational excellence across the equipment lifecycle.

3.1 Fuel Efficiency Optimization

Modern Tier 4 Final/Stage V engines combined with intelligent power management systems adjust output based on actual load requirements. Operator training programs further optimize consumption through proper operating techniques.

3.2 Wear Parts Management Program

Our wear parts monitoring system tracks component performance and recommends optimal replacement timing. Rotating and repositioning wear elements extends service life while maintaining product quality.

3.3 Production Ramp-Up Protocol

New site deployment follows a structured 5-day optimization protocol:

-

Day 1-2: Equipment setup and preliminary testing

-

Day 3: Gradual production increase with parameter adjustments

-

Day 4-5: Full production with final optimization

This systematic approach minimizes downtime during site transitions.

Investment Analysis: Clear Financial Modeling

Every project requires transparent financial planning. Our investment model evaluates:

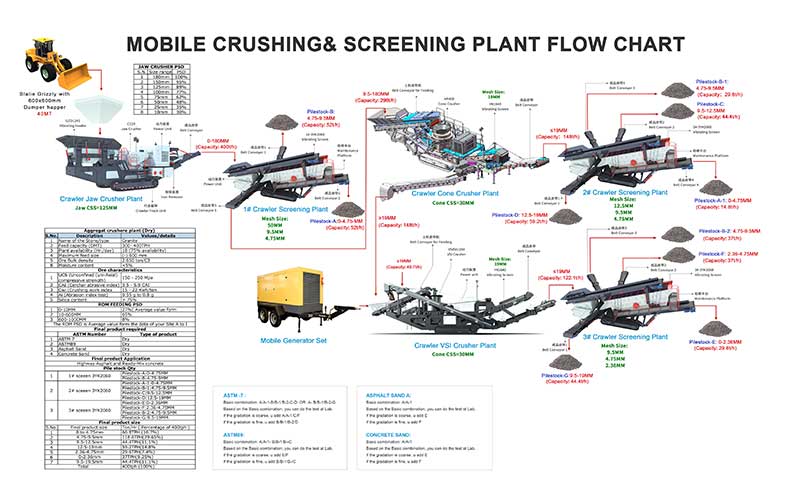

Equipment Configuration Analysis

-

Small-scale operations (150-250 TPH): Single unit setup with pre-screen

-

Medium operations (250-450 TPH): Two-unit configuration with independent crushing and screening

-

Large operations (450-800 TPH): Multiple units with closed-circuit design

Break-Even Analysis Framework

The model calculates payback periods based on:

-

Capital investment (equipment + ancillaries)

-

Operational costs (fuel, maintenance, labor)

-

Production output (tons per operating hour)

-

Material value (local market prices)

-

Utilization rate (projected operating days)

Typical payback periods range from 8-18 months depending on project scale and material value.

Frequently Asked Questions

Q1: How quickly can a tracked plant be relocated between sites?

A: With self-propelled mobility and hydraulic setup systems, most plants can be packed in 2-4 hours and operational at a new site within 4-8 hours of arrival, including setup and testing.

Q2: What maintenance intervals should operators follow?

A: We recommend daily inspections (fluids, wear parts), weekly maintenance (component lubrication, system checks), and scheduled major services at 500, 2000, and 5000 operating hours.

Q3: Can these plants process reinforced concrete with steel?

A: Yes. Standard configurations include overband magnets for continuous ferrous metal removal. For heavily reinforced concrete, we recommend optional reinforcement crushers and additional magnetic separation stages.

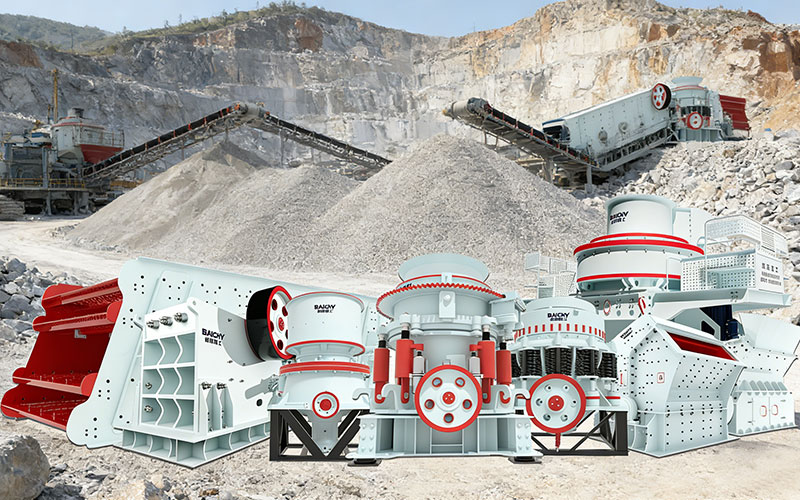

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!