Impact Crusher vs. Cone Crusher – What's the Difference?

Impact Crusher vs. Cone Crusher – What's the Difference?

In the field of mining crushing, impact crushers and cone crushers are two core types of medium and fine crushing equipment. As a manufacturer of mining crushing equipment with 20 years of experience, we deeply understand the decisive impact of choosing the right equipment on project efficiency, cost, and final product quality.

This article will delve into the working principles, performance characteristics, and applicable scenarios of both, and combine practical cases to help you make accurate decisions.

Overview: The fundamental difference lies in the crushing principle

The core difference between the two stems from their different crushing principles:

• Cone Crusher: Employs the principle of layered crushing. Within the crushing chamber formed by the moving and fixed cones, the material is repeatedly crushed by compression, bending, and shearing forces, thus achieving "layer crushing." This process is more gradual and controllable.

• Impact Crusher: Employs the principle of impact crushing. The material is either violently impacted and thrown out by the high-speed rotating rotor hammers, colliding with the impact plate or liner for crushing (impact crusher); or it is thrown at high speed into the crushing chamber, violently colliding with the shroud or the material itself for crushing (vertical shaft impact crusher/sand making machine). This is a high-energy, instantaneous process.

Product Advantages Comparison

Advantages of Cone Crusher:

1. High wear resistance and low operating costs: Employing layered crushing, wear primarily occurs between materials, resulting in a long service life for vulnerable parts (such as the jaw and crusher walls). It is particularly suitable for processing highly abrasive materials (such as granite and basalt).

2. Excellent particle shape and stable output: Produces uniform particle size with high cubic content and low needle-like and flaky particles, making it the preferred choice for high-quality aggregate production. Output is stable, and the discharge port is easily adjusted to control product particle size.

3. Relatively economical energy consumption: Typically, it consumes less energy per unit than an impact crusher for processing the same hard rock.

Advantages of Impact Crusher (Vertical Shaft Impact Crusher):

1. Excellent particle shape and strong plasticity: Especially suitable for producing construction sand and high-standard concrete aggregates. The finished particles are rounded and the gradation is adjustable.

2. Flexible switching between "stone-on-iron" and "stone-on-stone" crushing: The vertical shaft impact crusher can easily switch between shaping and sand making and crushing stone processing by adjusting the ratio of center feed and cascade feed, making it a multi-purpose machine.

3. Large feed size and high crushing ratio: The single-machine crushing ratio is large, simplifying the crushing process.

4. Relatively low equipment investment: The initial purchase cost is usually lower than that of a cone crusher of the same size.

Application Scenarios Guide

Preferential choice for cone crushers:

• Processing high-hardness, highly abrasive rocks (such as granite, river pebbles, quartz).

• Large-scale sand and gravel aggregate production lines that pursue high output and long-term continuous operation.

• Medium and fine crushing processes with strict and stable requirements for product particle size distribution.

• Projects that emphasize the control of post-processing wear parts consumption costs.

Preferential choice for impact crushers:

• Primarily processing medium to low hardness materials (such as limestone, calcite, dolomite).

• The core objective is to produce high-quality manufactured sand or aggregates with extremely high particle shape requirements.

• The production line needs flexible raw material adaptability and product structure adjustment capabilities.

• Initial equipment investment budget is highly sensitive.

Global Project Cases

1. Southeast Asia Granite Aggregate Project:

◦ Challenges: The material is extremely hard and highly abrasive, requiring a production capacity of 800 tons per hour, and the product is intended for high-standard commercial concrete.

◦ Solution: We designed a two-stage cone crusher process (coarse crushing + fine crushing). After coarse crushing, a single-cylinder hydraulic cone crusher performs medium crushing, followed by fine crushing and shaping using a multi-cylinder hydraulic cone crusher.

◦ Results: The production line operates stably, wear parts have exceeded expectations in lifespan, the finished aggregate has excellent particle shape, and the needle-like and flaky content is less than 5%, fully meeting customer requirements.

2. Middle East Limestone Sand and Aggregate Joint Project:

◦ Challenges: Primarily limestone, requiring the simultaneous production of 0-5mm high-quality manufactured sand and various aggregate specifications, with rapidly changing market demand.

◦ Solution: A "jaw crusher + impact crusher + vertical shaft impact crusher" scheme is adopted. The impact crusher serves as the medium crusher, while the vertical shaft impact crusher is adjusted to a "stone-on-stone" mode for shaping and sand production.

◦ Results: The production line is flexible and efficient. Through simple adjustments, the sand-to-gravel ratio can be freely controlled within a certain range, perfectly adapting to market demand fluctuations. The sand particle size and gradation meet the Class I sand standard.

Frequently Asked Questions (FAQ)

Q1: Which is more durable, a cone crusher or an impact crusher?

A1: When processing hard rock, the wear resistance of a cone crusher is generally far superior to that of an impact crusher. Its wear parts have a longer lifespan, resulting in lower operating costs. For medium to soft rock, the wear difference between the two is smaller.

Q2: I want to produce high-quality manufactured sand. Which should I choose?

A2: The vertical shaft impact crusher is recognized as the "king of sand production." It uses the centrifugal impact crushing principle, producing sand with rounded particle shape, continuous gradation, and adjustable fineness modulus, making it the preferred equipment for high-quality manufactured sand.

Q3: What are the differences in discharge adjustment methods between the two?

A3: Cone crushers primarily control particle size by adjusting the discharge opening size hydraulically or mechanically, offering precise and stable adjustment. Impact crushers mainly influence product particle size by adjusting rotor speed, impact plate gap (impact crusher) or cascade, and center feed ratio (vertical shaft impact crusher), offering more flexible adjustment but a relatively wider range.

Q4: Can they be substituted for each other?

A4: There is some overlap under specific operating conditions, but they are not completely interchangeable. For hard rock, high output, and low consumption requirements, cone crushers are a better solution. For medium-soft rock shaping and sand making, and flexible production requirements, impact crushers have significant advantages. The best solution is to scientifically select the appropriate crusher based on material characteristics, product requirements, and investment budget.

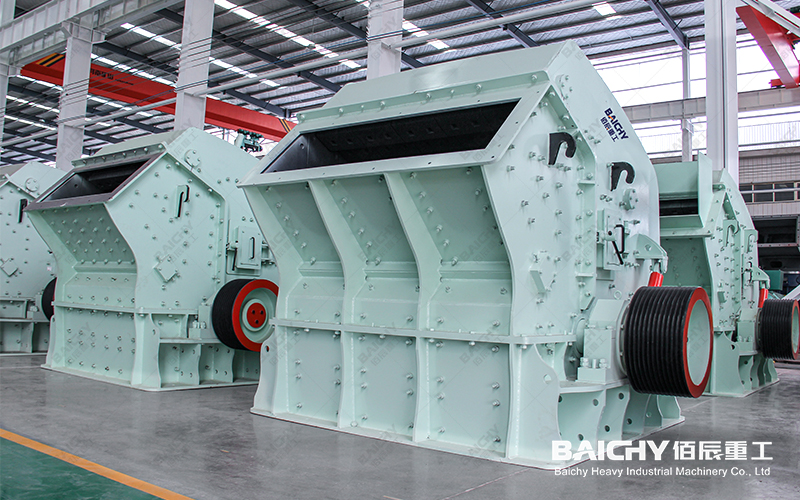

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.