Dolomite, as an important industrial raw material, requires crushing and processing as a key step in the production process. For many small and medium-sized production lines, achieving stable and efficient throughput is crucial for improving overall efficiency.

Let's delve into how to scientifically select equipment and optimize the process if the minimum processing capacity for crushing dolomite needs to reach 12 tons per hour, with a feed size range of 40 mm to 3 mm.

I. Understanding the Characteristics and Crushing Challenges of Dolomite

Dolomite is a mineral with medium hardness (Mohs hardness approximately 3.5-4), but it has a certain brittleness. If the crushing equipment or process is improper, it is easy to produce excessive fines, affecting the yield and economic benefits. The feed size range of 40mm to 3mm means that we are dealing with material that has undergone coarse or medium crushing, requiring further medium and fine crushing to achieve a more uniform particle size.

Core Challenges:

• Throughput Requirement: 12 tons per hour is the minimum standard; equipment selection needs to have some leeway to avoid insufficient output due to fluctuations in material moisture or hardness.

• Particle Size Control: The feed already has a certain size range, and the crushing equipment needs to have good particle size adjustment capabilities to ensure concentrated finished product particle size and low over-crushing rate.

II. Key Equipment Selection: Which Crusher is More Suitable?

For a processing capacity of 12 tons per hour and a feed range of 40mm-3mm, the following types of crushing equipment are common choices:

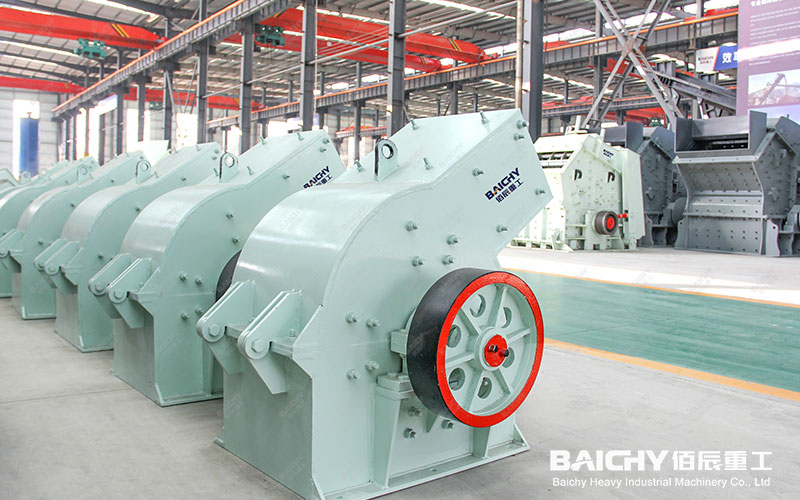

1. Hammer Crusher

• Advantages: Simple structure, large crushing ratio (can directly crush 40mm material to below 3mm in one pass), and moderate price.

• Applicable Scenarios: Suitable for medium and low hardness materials, with good crushing effect on dolomite. The output particle size can be controlled by adjusting the grate gap.

• Capacity Matching: A small to medium-sized hammer crusher (such as PCΦ800×600) can easily meet the 12 tons/hour requirement, and can even reach 15-20 tons/hour, leaving room for subsequent fluctuations.

2. Double Roll Crusher

• Advantages: Gentle crushing process, low over-crushing rate, and uniform finished product particle size (mainly controlled by the gap between the two rollers). • Applicable Scenarios: Particularly suitable for applications requiring high uniformity of particle size, such as chemical or glass raw material preparation.

• Capacity Considerations: To achieve 12 tons/hour, a model with a wider roller surface (e.g., 2PG1000×500) should be selected, and attention should be paid to the impact of roller surface wear on particle size stability.

3. Cone Crusher

• Advantages: Strong wear resistance, stable operation, and low energy consumption, suitable for continuous, large-scale production.

• Applicable Scenarios: If future plans include expanding production capacity, a cone crusher is a more long-term option.

• Note: The equipment investment is higher; for the minimum requirement of 12 tons/hour, it may be slightly "overkill," but the reliability is excellent.

Recommended Solution: For most small and medium-sized projects, the hammer crusher is the most cost-effective option, as it balances throughput, output particle size, and cost well.

III. Optimizing the Process Flow to Ensure Stable Compliance

In addition to selecting the right equipment, a reasonable process flow design is crucial:

• Uniform Feeding: It is recommended to equip a vibrating feeder to prevent material congestion or idling in the crushing chamber, ensuring continuous full-load operation of the equipment.

• Pre-treatment Stage: If the proportion of fine powder (<3mm) in the raw material is too high, consider adding a pre-screening stage to separate the qualified fine material directly, reducing the load on the crusher and increasing the effective throughput.

• Dust Removal Design: Dolomite crushing will produce a certain amount of dust. A matching pulse dust collector can improve the working environment and meet environmental protection requirements.

IV. Practical Points for Achieving 12 Tons/Hour Capacity

1. Allow for Equipment Parameter Margin: When selecting equipment, the theoretical processing capacity should ideally be selected at 15-18 tons/hour to cope with changes in material characteristics and the natural degradation of equipment efficiency.

2. Regularly Inspect Wear Parts: Wear of wear parts such as hammer heads, grate bars, and roller skins will directly affect the output particle size and throughput. Establishing a regular inspection and replacement system is key.

3. Control Material Moisture: If the moisture content of the dolomite raw material is too high (e.g., exceeding 5%), it is prone to sticking in the crushing chamber and on the screen, causing blockages and leading to a decrease in output. If necessary, simple air drying or oven drying of the raw materials can be considered.

Crushing dolomite to achieve a processing capacity of 12 tons per hour is technically mature and easily achievable. The key to success lies in selecting the appropriate crushing equipment (hammer crushers are a popular choice) based on your investment budget, desired finished product particle size, and long-term planning, supplemented by scientific process design and standardized operation and maintenance management.

We hope this analysis will provide inspiration for your project! If you have any further detailed questions regarding equipment selection or process design, please feel free to discuss them with us.

Further considerations: Is your next plan to directly produce aggregates for construction, or to use the material as a raw material for further processing in chemical, agricultural, or other fields? Different product directions may have further requirements for the final crushed particle shape and gradation.