Roads are the lifeblood of economic development, and high-quality aggregates (crushed stone) are the foundation for building strong and durable pavements. As a manufacturer of mining crushing equipment with 20 years of experience, we understand that choosing the right crushing and screening equipment is crucial for the success, cost control, and on-time delivery of road construction projects. This guide will take you through an in-depth look at integrated crushing and screening solutions for quarries.

I. Stringent Requirements for Aggregates in Road Construction

Different structural layers of roads (subbase, base course, surface course) have strict standards for aggregate particle size, shape, gradation, and cleanliness. For example, the base course requires aggregates with continuous gradation and sharp edges to achieve high load-bearing capacity and stability; while asphalt surface courses require aggregates with near-cubic particle shapes and low needle-like and flaky content to ensure pavement durability and rutting resistance. A well-designed crushing and screening production line is key to producing qualified aggregates.

II. Core Equipment Analysis: Crushing and Screening Systems

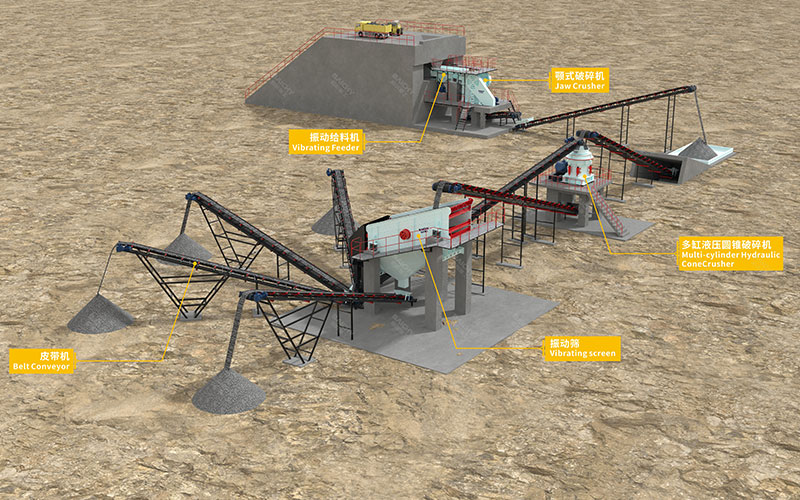

An efficient crushed stone production line typically consists of feeding, crushing, screening, and conveying systems. Crushing and screening are the core processes.

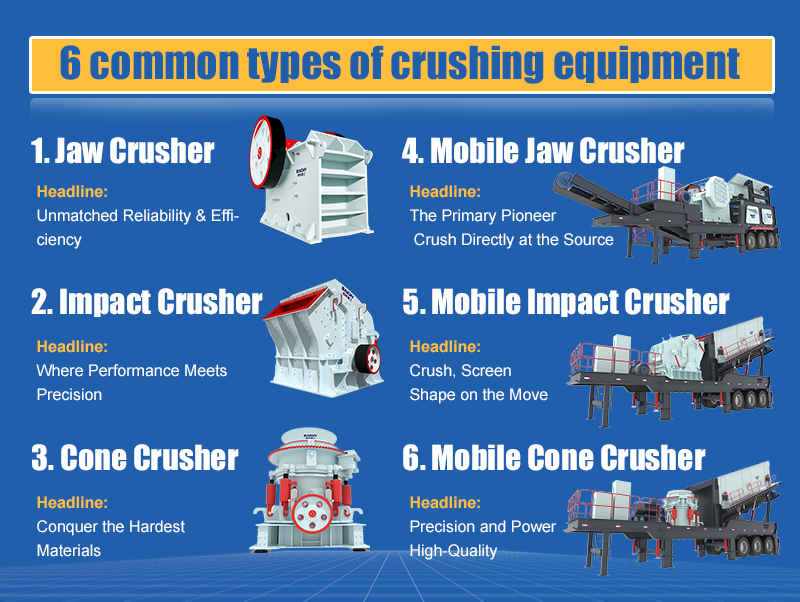

• 1. Primary Crushing (Coarse Crushing): Primarily responsible for crushing large stones after blasting to medium particle size. Jaw crushers are the preferred choice for primary crushing due to their robust structure, large processing capacity, and strong adaptability. Their working principle is similar to the jaws of an animal, crushing materials through the squeezing action of the moving and fixed jaws.

• 2. Secondary and Tertiary Crushing (Medium and Fine Crushing): Designed to further process the materials after primary crushing to obtain the desired particle shape and size. Cone crushers are suitable for medium and fine crushing, excelling at handling high-hardness materials, offering high crushing efficiency and good finished particle shape. Impact crushers are more suitable for medium to low hardness materials, producing high-quality aggregate with a high cubic particle content through the stone-on-stone principle, making them an ideal choice for improving particle shape.

• 3. Screening Equipment: Vibrating screens are the command center of the production line, responsible for classifying the crushed mixture according to size. Multi-layer vibrating screens can simultaneously separate products of various sizes (e.g., 0-5mm, 5-10mm, 10-20mm, etc.). Unqualified materials are returned to the corresponding crushers for reprocessing, forming a closed-loop cycle to ensure efficiency and finished product quality.

III. How to Plan the Optimal Production Line for Your Road Project?

There is no one-size-fits-all solution. Production line configuration needs to comprehensively consider the following factors:

• Raw material characteristics: Rock type (granite, limestone, etc.), hardness, abrasiveness, feed particle size.

• Capacity requirements: How many tons of material need to be processed per hour?

• Finished product requirements: What sizes of aggregate are needed? What are their proportions?

• Site and investment: Is the site limited? Is a fixed or mobile production line more suitable?

IV. Mobile Crushing Plants: A Flexible Choice for Modern Road Engineering

For linearly distributed highway projects, mobile crushing plants offer significant advantages. It can be moved directly to the work site, greatly reducing material transportation costs and environmental impact, achieving a highly efficient crush on the go operation mode, making it particularly suitable for projects with tight schedules and dispersed work sites.

Twenty years of industry experience have taught us that an optimized crushing and screening production line is a powerful support for cost reduction, efficiency improvement, and quality assurance in road construction projects. From equipment selection to process design, every detail is related to the final benefits of the project.

We are not only an equipment manufacturer, but also your trusted process partner. If you are preparing a crushing production line for a road project, please contact us. Our team of experts will provide you with a one-on-one customized solution.