Horizontal Shaft Impact Crusher

In numerous fields such as mining, building materials, and metallurgy, crushing is one of the first and most critical processes in material handling. Traditional vertical-shaft equipment such as jaw crushers and cone crushers have a long history, but facing increasingly demanding efficiency requirements and cost control pressures, the industry has been calling for better solutions. Horizontal crushers, as an innovative crushing technology, are becoming a powerful force driving the innovation of crushing processes with their unique structure and working principle.

As a manufacturer with 20 years of experience in mining crushing and grinding equipment manufacturing, we have witnessed every iteration of crushing technology. Today, we will combine our deep industry experience to provide you with a comprehensive analysis of the core advantages and application value of horizontal crushers.

Impact Crusher PDF, Download ↓↓↓

| Product Name | Horizontal Crusher |

|---|---|

| Brand | Baichy Heavy Industry |

| Place of Origin | Zhengzhou,China |

| Type | Impact Crusher |

| Capacity | 10-400tph |

| Motor Type | AC Motor |

| Motor Power | 45-315Kw |

| Application | Mines and quarries |

| Materials | Ores and hard materials |

| OEM/ODM | Acceptatble |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Customization options | customized on demand,sample processing... |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Working Principle and Core Structure of Horizontal Crushers

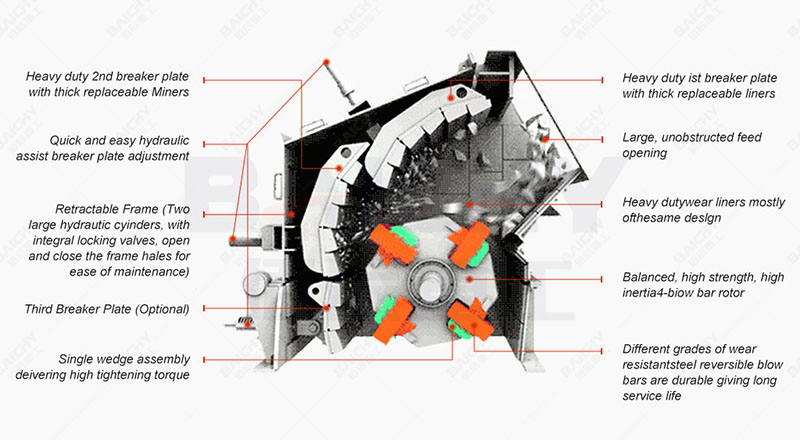

I. Working Principle and Core Structure of Horizontal Crushers

Unlike vertical-shaft crushers that rely on gravity and compression for crushing, the core of a horizontal crusher (usually referring to the horizontal design of an impact crusher or hammer crusher) lies in its horizontally placed rotor. The high-speed rotating rotor drives the hammers or impact plates, applying enormous impact energy to the material fed into the crushing chamber, causing the material to be rapidly crushed through the impact of the impact plates, counter-impact plates, and the material itself.

Its core structure includes:

• Heavy-duty rotor: The heart of the equipment, possessing extremely high rotational inertia, ensuring efficient and stable crushing force.

• Wear-resistant impact hammers: Made of high-strength wear-resistant alloy materials, they can be rotated or replaced, extending their service life.

• Hydraulic opening device: Convenient and quick opening of the machine frame facilitates maintenance and replacement of wear parts, significantly reducing downtime.

• Adjustable impact plates/liners: The output particle size can be flexibly controlled by adjusting the gap between the rotor and the impact plates.

II. Why Choose a Horizontal Crusher? Analysis of Four Core Advantages

1. High Crushing Ratio and Excellent Particle Shape: The impact crushing principle allows for a higher crushing ratio, enabling a single machine to complete medium and fine crushing operations. The resulting finished material is mostly cubic in shape, with excellent particle shape and low needle-like and flaky content, making it particularly suitable for high-standard aggregate production and concrete mixing plants.

2. High Efficiency and Energy Saving, Lower Operating Costs: The horizontal design allows for smoother material flow within the crushing chamber, reducing blockages and over-grinding. At high rotational speeds, the combination of stone-on-stone and stone-on-metal crushing principles utilizes energy more efficiently, resulting in lower power consumption per unit of output.

3. Flexible Adjustment, Multi-purpose Use: By simply adjusting the rotor speed or the gap between the impact plates, without replacing major components, the product's output particle size can be easily changed to meet the needs of different customers, offering exceptional application flexibility.

4. Easy Maintenance, High Reliability: The modular design and hydraulic opening mechanism make daily maintenance, inspection, and replacement of hammers or liners exceptionally simple. Combined with our 20 years of accumulated experience and mature manufacturing processes, the core components of the equipment are reinforced, ensuring long-term stable operation even in harsh mining environments.

III. Application Areas: Which Scenarios are More Suitable for Horizontal Crushers?

Horizontal crushers are not universally applicable, but they perform exceptionally well in their areas of strength:

• Medium-fine crushing of medium-hardness ores: Such as limestone, dolomite, gypsum, and coal.

• Recycling of construction waste: Its impact crushing can effectively process concrete blocks containing rebar and separate the rebar from the concrete.

• High-quality aggregate production lines: For the production of high-grade aggregates for highways, railways, and buildings with strict requirements on finished particle shape.

• Crushing of cement raw materials/clinker.

IV. Twenty Years of Dedication, Our Manufacturing Philosophy

Twenty years of deep industry experience have given us a profound understanding of the meaning of reliability for our customers. Every horizontal crusher we manufacture embodies the following considerations:

• Structural optimization based on massive data: We have accumulated data from thousands of application cases, and through finite element analysis, we perform dynamic analysis and reinforced design on key components such as the rotor, bearing housing, and frame.

• Design with maintainability as a priority: From the very beginning of equipment design, we have considered how to enable on-site engineers to perform maintenance more quickly and safely as a core consideration. • Rigorous Material and Quality Control: From the hammerheads to the main shaft, we carefully select materials and implement a quality inspection system throughout the entire casting, heat treatment, and machining processes, ensuring that every piece of equipment leaving our factory stands the test of time.

Choosing crushing equipment is not just about choosing a machine; it's about choosing a production philosophy and a long-term partner. Horizontal crushers represent the efficient, flexible, and economical direction of modern crushing technology. If you are looking for solutions to improve the efficiency of your crushing production line, enhance product quality, and reduce overall costs, horizontal crushers are definitely worth considering.

Welcome to contact us. With our 20 years of professional experience, we can provide you with the most suitable crushing solutions.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Aggregate crusher equipment

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.