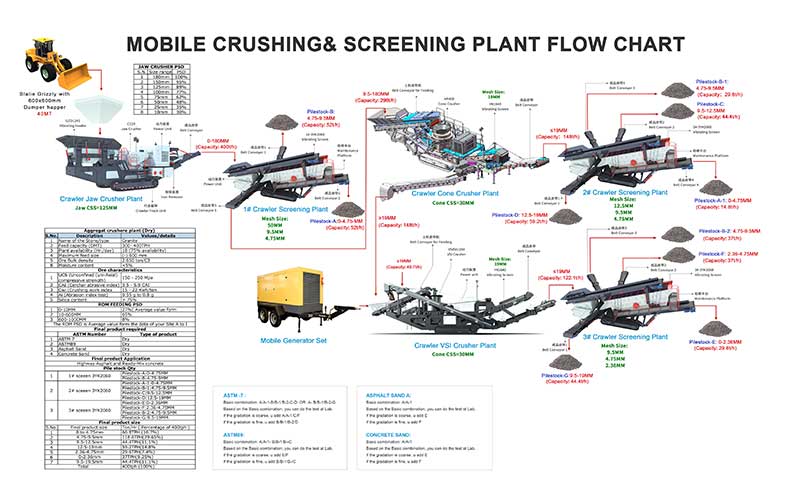

Vibrating screen on-site screening situation

The current mining production sector generally faces the technical challenge of insufficient screening efficiency for fine-grained materials. Traditional vibrating screens suffer from reduced screening efficiency and screen clogging when processing materials smaller than 3mm. As mineral resources become increasingly scarce and refined, higher demands are placed on the ability of screening equipment to handle fine-grained materials. The emergence of high-frequency vibrating screen technology provides a new technical solution for improving screening efficiency.

I. Working Principle and Technical Parameter Analysis

1.1 Characteristics of Traditional Vibrating Screen Technology

Traditional vibrating screens employ a low-to-medium frequency vibration mode, with a working frequency range of 12-20Hz and an amplitude of 4-6mm. Their screening mechanism mainly relies on the gravitational stratification and inertial motion of the material. When processing fine-grained materials with a moisture content exceeding 5%, screen clogging easily occurs, significantly reducing screening efficiency.

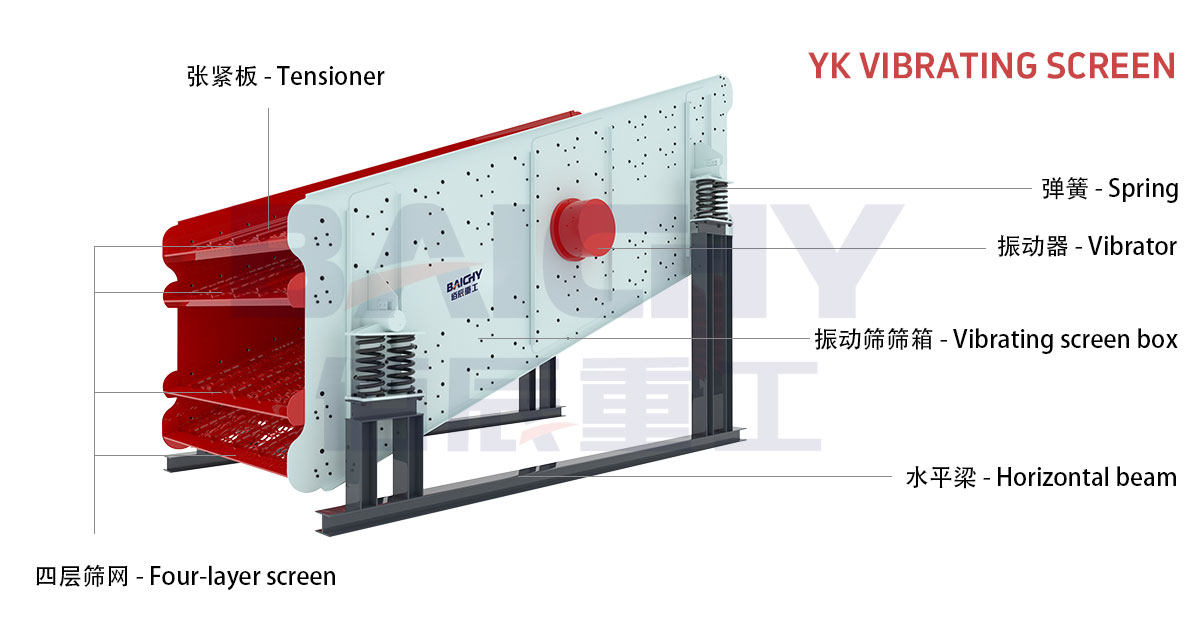

Vibrating-screen-structure-diagram

1.2 Innovation of High-Frequency Vibrating Screen Technology

High-frequency vibrating screens increase the working frequency to 25-50Hz, with the amplitude controlled at 2-4mm. By increasing the vibration acceleration to 6-8g, the kinetic energy and motion intensity of the material particles are enhanced. High-frequency vibration causes a stronger throwing motion of materials on the screen surface, increasing the probability of fine particles passing through the screen.

Technical Parameter Comparison Analysis:

| Performance Indicators | Traditional Vibrating Screen | High-Frequency Vibrating Screen |

| Operating Frequency | 12-20Hz | 25-50Hz |

| Amplitude Range | 4-6mm | 2-4mm |

| Vibration Acceleration | 3-5g | 6-8g |

| Suitable Particle Size | >3mm | 0.043-3mm |

II. Performance Advantages and Application Effects

2.1 Improved Screening Efficiency for Fine Particles

Actual production data shows that the screening efficiency of high-frequency vibrating screens for materials smaller than 3mm is 40%-60% higher than that of traditional equipment. In screening operations at the 0.074mm particle size level, the material recovery rate increased from 58% to 89%. High-frequency vibration effectively breaks down van der Waals forces and liquid bridge forces between fine particles, improving material stratification.

2.2 Improved Wet Screening Performance

The mechanical waves generated by high-frequency vibration effectively disrupt the surface tension of the liquid on the screen openings, preventing fine particles from adhering. In coal washing operations, the screen clogging rate decreased by 75% after 8 hours of continuous operation. Screening efficiency for materials containing moisture increased by approximately 40%, significantly improving the wet screening effect.

vibrating screening for mining

III. Economic Benefit Analysis

3.1 Operating Cost Structure

The motor power of the high-frequency vibrating screen is approximately 15% higher than that of traditional equipment, but the processing capacity is increased by 50%. Improved screening accuracy reduces energy consumption in subsequent grinding processes by 10%-15%. Equipment maintenance frequency is reduced, and effective operating time is increased by more than 25%.

3.2 Investment Return Analysis

Taking a concentrator with an annual processing capacity of 1 million tons as an example:

• Equipment investment increased by 30%

• Annual production increase benefit: 7.5 million yuan

• Increased energy consumption cost: 180,000 yuan

• Overall benefit increase: approximately 8.52 million yuan/year

The investment payback period is estimated at 8-14 months, depending on the ore properties and process conditions.

IV. Technology Selection Recommendations

4.1 Applicable Operating Conditions for High-Frequency Vibrating Screens

• Screening operations for materials with a fine particle content exceeding 30%

• Wet screening with a moisture content greater than 5%

• Separation of viscous materials

• Tailings dewatering and dry discharge processes

4.2 Applicable Operating Conditions for Traditional Vibrating Screens

• Screening operations primarily for coarse-grained materials

• Particle size classification of dried materials

• Application scenarios sensitive to equipment investment

V. Technological Development Trends

High-frequency vibrating screen technology is developing towards intelligentization. Automatic amplitude adjustment systems can optimize equipment parameters in real time based on material characteristics. The application of wear-resistant materials such as polyurethane screens extends the equipment's service life. In the future, high-frequency vibrating screens will further improve energy efficiency and expand the particle size processing range.

High-frequency vibrating screens achieve a significant improvement in screening efficiency by increasing vibration frequency and optimizing motion parameters. This technology is particularly suitable for screening fine-particle materials and is an important direction for the development of mineral processing technology. Equipment selection requires comprehensive consideration of material characteristics, process requirements, and return on investment.

VI. FAQ Regarding High-Frequency Vibrating Screens vs. Traditional Vibrating Screens

Q1: What is the core advantage of a high-frequency vibrating screen?

A1: The core advantage of a high-frequency vibrating screen lies in its superior screening efficiency for fine-grained materials. Through its high-frequency (25-50Hz) and low-amplitude (2-4mm) vibration characteristics, it effectively solves the screening problem for materials <3mm, and is particularly adept at handling wet, sticky, fine-grained materials that are prone to clogging with traditional vibrating screens, increasing efficiency by 40%-60%.

Q2: Is the energy consumption of a high-frequency vibrating screen significantly higher than that of a traditional vibrating screen?

A2: Yes, the motor power of a single unit is indeed higher, and energy consumption is typically about 15% higher than that of a traditional vibrating screen of the same specifications. However, it must be evaluated from the perspective of system efficiency: its processing capacity is increased by about 50%, and the improved screening accuracy can reduce subsequent grinding energy consumption by 10%-15%, while also reducing downtime. In summary, the payback period is typically 8-14 months, with overall positive economic benefits.

Q3: Under what circumstances should a traditional vibrating screen be preferred?

A3: In the following operating conditions, a traditional vibrating screen remains a more economical and practical choice:

• Coarse material particle size: Primarily processing materials >10mm.

• Dry screening: Materials are dry and non-sticky.

• Extremely limited investment budget: And low requirements for fine particle recovery rates.

• Situations where there are stricter limitations on equipment operating noise and foundation vibration.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!