Gold Ore Processing Small Hammer Mill

In the field of gold mining, especially for small and medium-sized mines, inpidual miners, or experimental projects in remote areas, efficiently and economically crushing ore is crucial to determining initial project costs and efficiency.

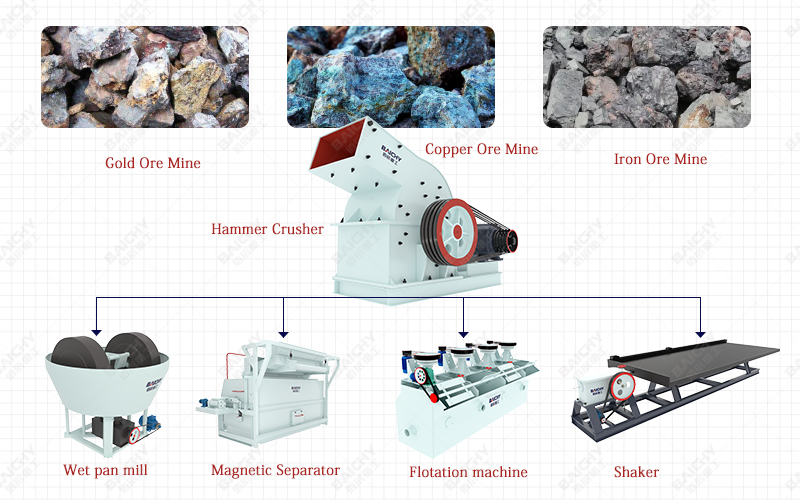

Crushing is the first and most critical step in the gold ore processing flow. Among numerous crushing equipment options, small hammer crushers have become the preferred choice for many operators due to their unique advantages.

Gold ore is usually hard and often contains abrasive minerals such as quartz. While traditional jaw crushers are reliable, they sometimes fall short in terms of flexibility, output fineness, and handling of sticky or wet materials. Large production lines, on the other hand, require high investment and are not suitable for small-scale operations.

Small means low investment costs, easy installation, and flexible mobility, making it ideal for scenarios with low processing volumes or those requiring frequent relocation. Hammer type represents its high crushing ratio, uniform product particle size, and simplified process. Small hammer crushers combine these two aspects, precisely meeting the core needs of the small and medium-sized gold mining market for efficiency, flexibility, and economy.

Gold ore crusher, small hammer crusher, gold processing equipment

How does a small hammer crusher work?

A small hammer crusher mainly consists of a casing, rotor, hammers, grate bars, and a driving device. Its working principle is simple yet powerful:

1. Feeding: The raw ore (usually already coarsely crushed to a certain particle size) is fed into the machine through the feed opening.

2. Impact Crushing: The high-speed rotating rotor drives the hammers, violently impacting the ore falling into the machine, causing it to collide at high speed with the crushing plate.

3. Grinding and Screening: The ore is repeatedly struck and ground between the hammers and the crushing plate. Material smaller than the grate bar gap is discharged, while larger pieces remain in the chamber to be crushed until they reach the required particle size.

This equipment can crush gold ore to a medium-fine particle size (e.g., 10-25mm or less) in a single pass, creating favorable conditions for subsequent grinding or direct cyanide leaching.

Gold Ore Processing Small Hammer Mill

Core Advantages: Why choose it for gold ore processing?

Based on our 20 years of manufacturing and customer feedback experience, small hammer crushers offer the following five major advantages in gold ore processing:

1. High crushing ratio and simplified process: A single machine can achieve a crushing ratio of up to 10-25 or even higher, reducing the number of crushing stages, simplifying the process flow, and lowering investment in plant and supporting equipment.

2. Uniform product particle size and less over-crushing: By adjusting the grate gap, the output particle size can be effectively controlled. Uniform particle size is beneficial for improving subsequent grinding efficiency or leaching rate, and reduces gold loss in fine powders.

3. Compact structure and flexible mobility: The equipment is small in size and light in weight, and can be installed as a fixed unit or mounted on a mobile chassis to form a mobile crushing unit, making it ideal for mining areas with complex terrain.

4. Low investment and operating costs: The purchase cost is far lower than that of cone crushers or compound crushers with equivalent processing capacity. The simple structure and easy maintenance result in more competitive daily energy consumption and maintenance costs.

5. Strong adaptability to muddy and wet ores: Compared with jaw crushers, its grate structure has a relatively lower risk of clogging when dealing with slightly sticky and wet materials (pre-treatment is still required in extreme cases).

Actual Application Case Study

One of our clients owns a small vein gold mine in Africa. The ore hardness is medium (f=8-10), the initial budget was limited, and the mining area was scattered. We recommended a PC series small hammer crusher with a capacity of 5-8 tons per hour.

• Configuration: The equipment has a 22kW motor, an input particle size of <200mm, and an adjustable output particle size (≤15mm).

• Application: The equipment was combined with a small jaw crusher (for primary crushing) and a belt conveyor to form a simple production line.

• Results: The production line was installed and commissioned within three days. The crushed product had a uniform particle size and was directly fed into the ball mill, increasing grinding efficiency by approximately 15%. The client reported that the equipment ran stably, and thanks to its flexible mobility, it could be quickly moved to the next mining point after completing operations at one point, greatly improving asset utilization. The investment cost was recovered within six months.

Related Equipment Recommendations and Selection Suggestions

To select a suitable small hammer crusher, the following points should be considered. We recommend:

• Clarify processing capacity and particle size: Determine how many tons of ore need to be processed per hour and the required final output particle size. This is the fundamental basis for selection.

• Analyze ore properties: Understand the hardness, moisture content, clay content, and silica content (abrasiveness) of the gold ore. For high-silica ore, we recommend using high-manganese steel or composite alloy hammer heads.

• Consider power supply and mobility: Is the power supply in the mining area stable? Does the equipment need to be mobile? We can provide mobile solutions with diesel engine or electric motor drives.

• Focus on manufacturer qualifications: Choose a manufacturer with many years of experience, like us, to ensure mature equipment technology, robust materials, and reliable after-sales service and supply of wear parts (such as hammer heads and grate bars).

Frequently Asked Questions (FAQ)

Q1: What is the maximum particle size of gold ore that a small hammer crusher can handle?

A1: Generally, the recommended feed particle size is no more than 200mm. If the raw ore size is larger, a jaw crusher is needed for primary crushing.

Q2: What is the service life of the hammer heads? Is replacement complicated?

A2: The service life depends on the abrasiveness of the ore; generally, it can last for hundreds of hours when processing medium-hardness gold ore. Our design allows for easy opening and replacement, usually completed by 1-2 workers in a few hours.

Q3: How does the equipment handle ore with high moisture content?

A3: It can handle slightly wet ore. If the ore is highly viscous and has high moisture content, it is recommended to air-dry or use drying equipment for pretreatment, or inform us during the selection process so we can adjust the grate bar structure accordingly.

Q4: What are the advantages compared to roller crushers?

A4: The main advantages are a higher crushing ratio and a stronger ability to process lumpy ore. Roller crushers are more suitable for medium and fine crushing, requiring a more uniform feed particle size, and are prone to producing flaky products.

Q5: Can you provide customized solutions?

A5: Absolutely. With 20 years of experience in design and manufacturing, we can provide customized solutions and equipment, from single machines to small-scale complete production lines, based on our clients' specific ore samples, site conditions, and budget.

In summary, for gold ore processors seeking an efficient, flexible, and economical entry-level solution, a small hammer crusher is a proven and reliable choice. It not only lowers the initial investment threshold, but its efficient crushing performance also lays a solid foundation for the success of the entire mineral processing process. If you are looking for suitable crushing equipment for your gold mining project, please feel free to contact us and share your needs. We will provide you with the best solution based on our professional experience.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.