Concrete Crushing Plant

With the acceleration of global urbanization and continuous infrastructure upgrades, the amount of construction waste generated is increasing year by year. Waste concrete accounts for a significant proportion of this. How to efficiently and environmentally process this waste concrete and transform it into reusable aggregate has become a crucial issue for the construction and mining machinery industries.

As a manufacturer of mining crushing equipment with 20 years of professional experience, we understand that choosing the right concrete crusher is crucial to the economic and environmental benefits of recycling projects.

This article will provide an in-depth analysis of seven mainstream crushers used for concrete recycling, offering a comprehensive reference for your investment decisions.

Core Equipment for Concrete Recycling Crushing: 7 Models Explained

Jaw Crusher - A Reliable Choice for the Initial Crushing Stage

1. Jaw Crusher - A Reliable Choice for the Initial Crushing Stage

The jaw crusher is the most common initial crushing equipment in concrete recycling production lines. Its working principle is to crush large pieces of waste concrete to a medium particle size through the squeezing action between the moving jaw and the fixed jaw.

Advantages:

• Robust structure, high processing capacity, especially suitable for crushing large pieces of concrete containing reinforcing steel.

• Large feed opening, capable of processing large-sized waste building materials.

• Relatively simple maintenance and controllable operating costs.

Applicable scenarios: Primary crushing in stationary or large mobile concrete recycling plants.

Impact Crusher - Highly Efficient Medium and Fine Crushing Expert

2. Impact Crusher - Highly Efficient Medium and Fine Crushing Expert

The impact crusher utilizes a high-speed rotating rotor to impact materials, causing them to be repeatedly crushed by impact on the impact plates. The finished product has good particle shape, mostly cubic.

Advantages:

• High crushing ratio and high production efficiency.

• Excellent aggregate particle shape, beneficial to the strength of recycled concrete.

• Easy to adjust discharge particle size.

Applicable scenarios: Secondary crushing, suitable for the production of recycled building materials with high requirements for aggregate particle shape.

Cone Crusher - The Nemesis of Hard Materials

3. Cone Crusher - The Nemesis of Hard Materials

The cone crusher uses an eccentric sleeve to drive the rotating cone, achieving layered crushing of materials. It is particularly suitable for processing concrete waste with high hardness and strong abrasiveness.

Advantages:

• Stable operation, long service life of wear parts, and low long-term operating costs.

• High crushing efficiency and relatively low energy consumption.

• Easy to automate.

Applicable scenarios: Fixed production lines handling large volumes of highly abrasive materials in the medium and fine crushing stage.

Mobile Crushing Plant - A Flexible Operation Solution

4. Mobile Crushing Plant - A Flexible Operation Solution

A mobile crushing plant is not a single machine, but rather integrates main crushers such as jaw crushers, impact crushers, or cone crushers onto a mobile vehicle chassis. This is the current trend for on-site concrete recycling.

Advantages:

• Extremely flexible, can be moved with the project site, saving significant transportation costs.

• Quick deployment and commissioning, suitable for demolition projects in urban areas.

• Integrated design reduces on-site installation work.

Applicable scenarios: On-site crushing of construction waste, urban demolition projects, multiple scattered small and medium-sized construction sites.

Impact Crusher (Sand Making Machine) - The Shaper of High-Quality Manufactured Sand

5. Impact Crusher (Sand Making Machine) - The Shaper of High-Quality Manufactured Sand

The impact crusher (VSI) uses the "stone-on-stone" or "stone-on-iron" principle to further shape and finely crush primary crushed concrete aggregate, producing high-quality recycled fine aggregate (manufactured sand).

Advantages:

• Produces aggregate with rounded particle shape, continuous gradation, and high quality.

• Helps remove some of the aged cement paste adhering to concrete fragments, improving the performance of recycled aggregates.

Applicable Scenarios: The downstream of concrete recycling production, used to manufacture high-value recycled sand.

Hammer Crusher - A Simplified Solution for One-Step Crushing

6. Hammer Crusher - A Simplified Solution for One-Step Crushing

The hammer crusher relies on hammers hinged to a rotor to impact materials at high speed, achieving the required particle size in a single step.

Advantages:

• High crushing ratio, enabling single-stage crushing and simplifying the process.

• Compact equipment structure, potentially lower investment costs.

Points to note: When processing concrete containing a large amount of reinforcing steel, attention should be paid to hammer wear and entanglement.

Applicable scenarios: Small to medium-sized recycling projects with less stringent requirements on product particle size.

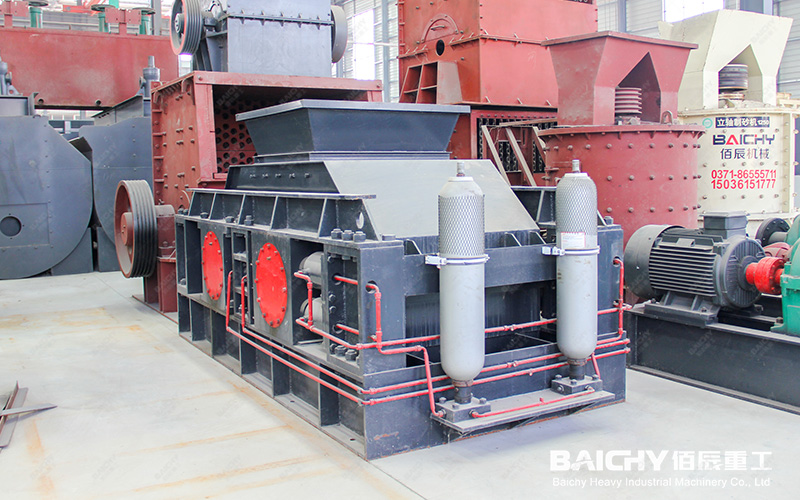

Double Roll Crusher - Suitable for crushing sticky and wet materials

7. Double Roll Crusher - Suitable for crushing sticky and wet materials

The double roll crusher uses two opposing rotating rollers to compress and grind materials. It is suitable for construction waste mixtures with a certain amount of moisture and high viscosity.

Advantages:

• Less over-crushing, resulting in uniform product particle size.

• Simple structure and reliable operation.

Applicable scenarios: For processing complex construction waste mixtures with high moisture content, used for medium to fine crushing.

Comparison of Core Parameters of 7 Types of Concrete Crusher

The table below comprehensively compares the main features of each type of equipment to help you make a quick decision:

| Crusher Type | Main Crushing Method | Optimal Feed Size | Typical Discharge Size | Advantages | Applicable Stage |

| Jaw Crusher | Extrusion | Large (<1200mm) | Medium-coarse (100-350mm) | Robust and durable, handles large pieces | Primary crushing |

| Impact Crusher | Impact | Medium (<500mm) | Medium-fine (0-50mm) | Good particle shape, large crushing ratio | Secondary crushing |

| Cone Crusher | Lamination and extrusion | Medium (<300mm) | Medium-fine (3-60mm) | High efficiency and energy saving, wear-resistant | Secondary/tertiary crushing |

| Mobile Crushing Station | Integrated System | Depends on the host | Adjustable | Flexible and mobile, easy to relocate | All stages (on-site operation) |

| Impact Crusher | Impact, collision | Small (<50mm) | Fine (0-5mm sand making) | Excellent Particle Shape, High Sand Production Rate | Sand Making and Shaping |

| Hammer Crusher | Impact | Impact (<1000mm) | One-pass Medium to Fine Crushing | Single-stage Crushing, Simple Process | Single-stage or Primary Crushing |

| Roll Crusher | Extrusion, Grinding | Medium (<40mm) | Fine (2-10mm) | Less Over-crushing, Uniform Particle Size | Fine Crushing/Wet/Adhesive Materials |

How to Choose Equipment for Your Project?

When selecting a concrete crusher, the following factors should be considered:

1. Material Characteristics: Maximum size, hardness, steel reinforcement content, and impurities (such as wood, plastic) of the concrete blocks.

2. Capacity Requirements: How many tons of waste concrete need to be processed per hour.

3. Finished Product Requirements: Target particle size, shape, and intended use of recycled aggregate (e.g., for roadbed or recycled concrete).

4. Operating Site: Fixed plant or construction site requiring frequent relocation? This directly determines whether to choose a fixed production line or a mobile station.

5. Investment and Operating Costs: This includes equipment procurement, installation, energy consumption, wear parts consumption, and maintenance costs.

As a manufacturer with 20 years of experience, our advice is: For large-scale, long-term recycling plants, stationary production lines (combined jaw crusher + cone crusher/impact crusher) are the most efficient and stable choice. For scattered, short-term demolition projects within cities, mobile crushing plants are undoubtedly the most cost-effective and flexible solution.

Choosing the right crushing equipment is the cornerstone of a successful concrete recycling business. From robust jaw crushers to flexible mobile crushing plants, each piece of equipment plays a crucial role in the resource recycling chain. We hope this guide, based on 20 years of industry experience, will help you plan your concrete recycling project more clearly and contribute to the green and sustainable development of the construction industry.