Complete Gold Centrifugal Concentrator | BC-30 Configuration

Below is a detailed analysis of the needs of a Bolivian customer based on inquiries from BAICHY, along with the information framework typically prepared for you as a supplier (or information provider).

Analysis of Customer Needs

1. Clear Objectives: You require a complete, immediately operational system, not just the main unit. Your mention of "motors, pumps, control panels, and all accessories" is crucial, avoiding potential compatibility and integration issues during subsequent procurement.

2. Specific Model: Mentioning "BC-30 or equivalent" indicates you've conducted preliminary research. BC-30 typically refers to a centrifugal concentrator with a processing capacity of approximately 30 tons/hour, suitable for concentrate processing in small to medium-sized placer gold mines or gravity separation plants. This allows us to precisely target our product line.

3. Focus on After-Sales Support: Requesting a "spare parts list and warranty terms" demonstrates your concern not only for purchase cost but also for the equipment's total lifecycle costs, operational reliability, and long-term support—a sign of a mature buyer.

4. Potential Application Inferences: Based on the selected equipment type, your project may involve:

◦ Roughing or cleaning of placer gold deposits.

◦ Recovery of liberated coarse gold particles from rock gold deposits via gravity separation after crushing and grinding.

◦ Gold recovery from heavy gold minerals or old tailings.

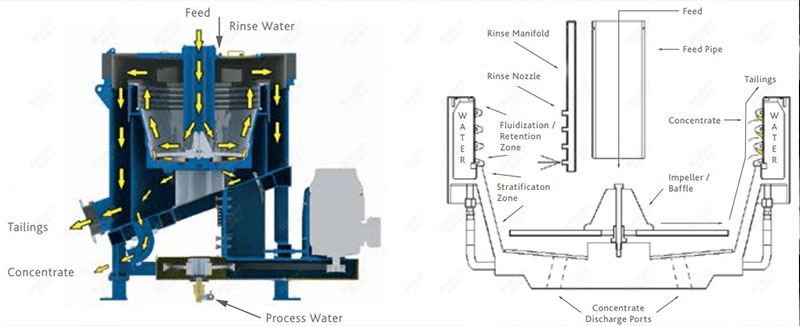

Centrifugal concentrator structure and principle

Comprehensive Information to Meet Your Needs

Based on your needs, a professional quotation or solution should include the following:

Part One: Core Equipment Configuration List (Taking the BC-30 equivalent model as an example)

| Component Category | Detailed Description | Remarks |

| 1. Main Unit | Centrifugal concentrator body, including centrifugal drum, feeder, discharge device, concentrate washing system, frame, and protective cover. | Core sorting components, typically made of wear-resistant steel or lined with polyurethane/rubber. |

| 2. Power System | Main Motor: Typically a 7.5-11kW 4-pole explosion-proof/outdoor three-phase asynchronous motor, adaptable to your site voltage (e.g., 380V/50Hz or 440V/60Hz). | Provides the core power for the centrifugal drum rotation. |

| 3. Water Supply System | Water Pump: Matching centrifugal clean water pump, power approximately 1.5-3kW, with filter. Includes necessary valves and piping. | Used for concentrate washing and possible sorting makeup water, crucial for normal equipment operation. |

| 4. Control System | Control Panel: Integrated starter cabinet, containing circuit breakers, contactors, thermal overload protection, emergency stop button, and run/fault indicator lights for the main motor and water pump. | Optional PLC and touch screen for automated flushing control. Ensures safe and convenient operation. |

| 5. Necessary Accessories - Feed hopper and regulating valve | - Finished concentrate collection bucket/bag - Included tools (wrench, etc.) - Anchor bolts - Electrical terminal blocks - Lubricating grease |

- Equipment operation and maintenance manual (Chinese and English) Ensure immediate installation and commissioning upon unpacking. |

Part Two: Recommended Spare Parts List (For Initial Purchase)

To ensure continuous equipment operation, it is recommended to purchase the following consumable parts and critical spare parts for the initial purchase:

| Spare Part Name | Estimated Service Life | Recommended Initial Purchase Quantity |

| Centrifugal Drum Liner (Polyurethane/Rubber) | 6-12 months (depending on ore abrasiveness) | 1 set |

| Flush Water Nozzle | 3-6 months | 2-4 pieces |

| Feed Hose/Line | 12 months | 1 set |

| Main Bearing (if replaceable) | 2-3 years | 1 set |

| Sealing Ring/O-ring Kit | Replace during maintenance | 1 set |

| Motor Belt (if belt driven) | 6-12 months | 1-2 sets |

Part Three: Standard Warranty and Service Terms

This typically includes the following, subject to the contract:

• Warranty Period: Main unit typically 12 months, from the date the equipment arrives at its destination and is installed and commissioned, or 12-15 months from the date of shipment (whichever comes first). Purchased components such as motors and pumps are covered by their original manufacturer's warranty (usually 12 months).

• Warranty Coverage: Covers failures caused by defects in materials and manufacturing processes. Excludes:

◦ Normal wear and tear on consumable parts (e.g., linings, nozzles).

◦ Damage caused by misoperation, overloading, unauthorized modifications, natural disasters, or improper maintenance.

◦ Consumables.

• Technical Support: Free remote technical guidance (telephone, email, video). On-site installation guidance, commissioning, and operation training services are available for a fee (travel expenses not included).

• Spare Parts Supply: Free replacement of defective parts during the warranty period. After the warranty period, spare parts and technical support are provided at preferential prices for life.

Gold Concentrate of Centrifuge

To provide you with the most accurate quote and solution, we usually need you to confirm the following information:

1. Processing Material Details: Ore type (placer or rock?), feed particle size (mm), expected feed concentration, approximate gold grade and particle size characteristics? 2. Site Conditions: Power supply voltage and frequency? Is the installation environment indoors or outdoors? What is the water supply situation?

3. Production Targets: What are your expected throughput (tons/hour) and recovery rate targets?

4. Logistics Information: What is the destination port? This will affect freight cost estimates.

You have provided an excellent starting point for your needs. A complete proposal will be developed around the above framework and customized based on your responses to the clarified questions. Our next step can be to prepare a detailed pro forma invoice for you, including equipment specifications, a clearly defined contract, and optimized spare parts procurement recommendations based on your material needs.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!