China Crusher Manufacturer, Supplier

Why are Made in China crushers attracting global attention?

Chinese crusher manufacturers and suppliers are not just a simple industry label, but a crucial link in the global supply chain for mining, aggregate, construction, and recycled resource industries. After decades of technological accumulation and market experience, Chinese manufacturers have transformed from early imitators and followers into synonyms for technological innovation, large-scale production, and high cost-effectiveness in the global crushing and screening equipment market. This article, from the perspective of a manufacturer with 20 years of deep industry experience, will delve into this topic, showcasing the true strength and future prospects of Chinese manufacturing.

Stone Crushing Plant PDF,Download ↓↓↓

In-Depth Analysis of the Chinese Crusher Manufacturing Industry

Industry Overview: A Comprehensive Rise from Scale to System

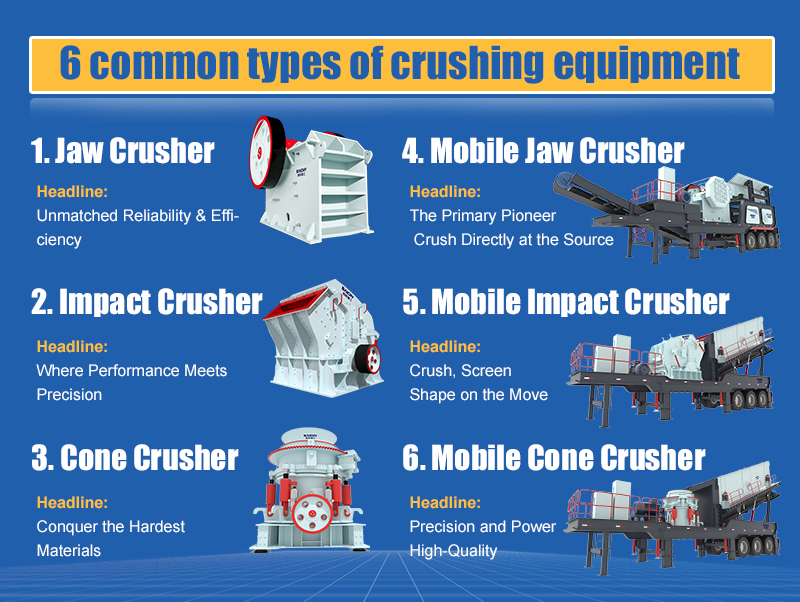

The Chinese crusher manufacturing industry, relying on the vast domestic infrastructure construction and mineral resource development market demand, has formed the world's most complete and largest industrial cluster. From core jaw crushers, cone crushers, and impact crushers to supporting feeding, screening, and conveying equipment, the upstream and downstream of the industrial chain are highly efficient and collaborative. This not only guarantees supply stability but also continuously drives technological iteration and cost optimization through sufficient internal competition, enabling Chinese suppliers to provide technologically advanced and reliable equipment at highly competitive prices.

Twenty Years of Dedication, Our Core Advantages

As a part of this thriving industry, our twenty years of dedication have forged a unique value that sets us apart from ordinary suppliers.

1. Technological Accumulation and Continuous Innovation

For twenty years, we have witnessed the industry's transformation from traditional to intelligent. Our engineering team works closely with the front lines, understanding various ore characteristics and working conditions. We not only master mature designs and processes but also continuously conduct research and development in energy saving, intelligent control, and wear-resistant materials, ensuring that every piece of equipment integrates reliability and cutting-edge technology.

2. Full-Chain Manufacturing and Quality Control

From casting and forging to precision machining, we achieve independent production in key links, ensuring controllable quality at the source for core components (such as rotors, main shafts, and frames). The consistently applied ISO quality management system, along with rigorous factory testing (no-load and load tests), is the cornerstone of our commitment to delivering reliable equipment to our customers.

3. Customized Solutions and Global Service Network

We understand that no two mines or projects are exactly alike. Therefore, we provide a complete set of solutions, from on-site surveys, process design, and equipment selection to installation guidance, operation training, and lifelong after-sales support. Our ever-improving global service network ensures that customers receive timely technical support and spare parts supply, no matter where they are located.

China Crusher Manufacturer, Supplier

Case Studies: Our Equipment Around the World

Southeast Asia Granite Crushing Production Line

In a large granite quarry in Malaysia, we provided a complete crushing and screening production line with a capacity of 800 tons per hour. The core equipment includes our high-performance hydraulic jaw crusher and multi-cylinder hydraulic cone crusher. After three years of operation, the equipment has operated stably, producing excellent aggregate particle shape, fully meeting the high standards for commercial concrete aggregate in the region, giving the customer a significant competitive advantage.

Central Asia Iron Ore Crushing System Upgrade

A certain iron ore plant in Kazakhstan had an existing system with low efficiency and high energy consumption. We upgraded their secondary crushing stage, replacing the old equipment with a large inertial cone crusher. After the upgrade, the product over-crushing rate decreased by 15%, and system energy consumption decreased by approximately 20%, effectively improving the iron concentrate recovery rate, and the return on investment far exceeded the customer's expectations.

Related Product Recommendations

Based on different application scenarios, we recommend the following core equipment series:

C Series Jaw Crusher: High crushing ratio, robust and durable, a reliable choice for primary crushing.

HP Multi-cylinder Hydraulic Cone Crusher: Suitable for medium and fine crushing, highly automated, and produces excellent product particle shape.

VSI Impact Crusher: Designed specifically for high-quality manufactured sand and aggregate shaping, combining crushing and shaping functions.

Mobile Crushing Station: Wheel-mounted and crawler-mounted options, suitable for flexible operations such as demolition waste processing and on-site recycling of construction aggregates. H2: Frequently Asked Questions (FAQ)

1. What are the advantages of Chinese crushers compared to European brands?

Our core advantages lie in superior cost-effectiveness, faster delivery times, and more flexible customization services. While offering comparable technical performance, Chinese equipment significantly reduces customers' initial investment costs. At the same time, our rapid response to market demands and personalized service better adapt to the specific project needs of our customers.

2. How do you guarantee the long-term stable operation and after-sales service of equipment overseas?

We have established a three-tiered after-sales support system:

1) Remote online diagnostics;

2) Spare parts warehouses and service engineers in key regions;

3) Provision of detailed maintenance manuals and regular follow-up visits.

In addition, we provide comprehensive operation and maintenance training for the equipment to ensure that the customer's team can perform standardized daily maintenance.

3. Can you conduct tests and design solutions based on my raw material samples and final product requirements?

Absolutely. We encourage customers to provide representative raw material samples and clear product specifications. We can utilize our own testing center to conduct crushing tests, obtain key data, and based on this, design the most economical and efficient process equipment solution tailored to your needs, and provide detailed capacity and power consumption reports.