Vertical Shaft Impact Crusher | Challenging The Ultimate Particle Size

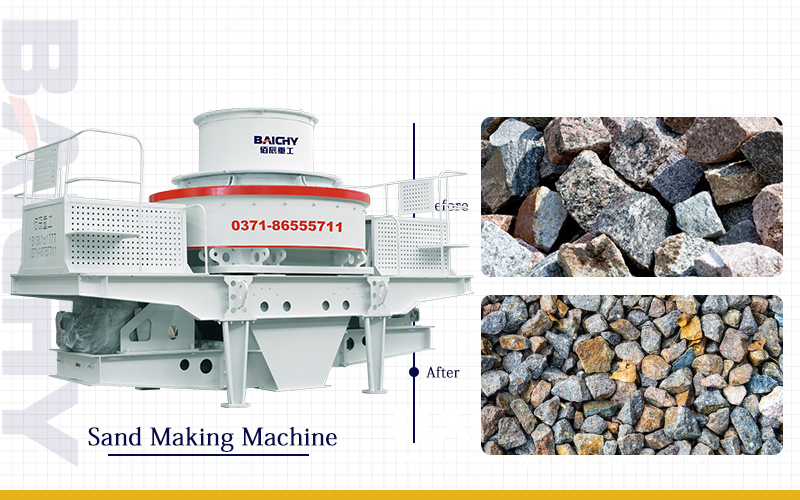

In the mining crushing industry, the pursuit of finer and more uniform product particle size has always been the core of technological breakthroughs. Vertical shaft impact crushers, as key technological equipment in modern crushing processes, are constantly pushing the limits of particle size control with their unique stone-on-stone and stone-on-iron crushing principles.

As a manufacturer of mining crushing equipment with 20 years of professional experience, we are committed to providing global customers with comprehensive solutions for all scenarios, helping them optimize product particle shape and maximize production capacity while reducing energy consumption.

Core Product Advantages: Why Choose Our Vertical Shaft Impact Crusher?

1. Ultimate Particle Size Control: Through optimized rotor design and speed regulation, precise control of the output particle size is achieved, making it particularly suitable for manufactured sand production and fine crushing operations, easily obtaining cubical, well-graded final products.

2. High Efficiency and Energy Saving: The unique centrifugal crushing principle results in high energy utilization. Under the same particle size requirements, it consumes less energy than traditional equipment, significantly reducing customers' long-term operating costs.

3. High Wear Resistance and Low Maintenance: Key components utilize high-quality alloy wear-resistant materials, and the flow channel design reduces direct friction between vulnerable parts and materials, extending service life and minimizing downtime for maintenance.

4. All-Scenario Flexibility: The equipment has a compact structure, adaptable to both fixed and mobile production line configurations. It can handle high-hardness materials such as granite and basalt, as well as medium-hardness materials like limestone, with ease.

5. Intelligent Control: An optional advanced automatic control system monitors key parameters such as vibration and temperature in real time, enabling intelligent operation and fault warnings, ensuring continuous and stable production.

Vertical Shaft Impact Crusher Challenging The Ultimate Part

Wide Application Scenarios

The vertical shaft impact crusher is a versatile machine, excelling particularly in the following scenarios:

• Manufactured Sand Production: Meets the stringent particle shape and gradation requirements for sand used in construction, bridges, and high-grade concrete.

• Fine Ore Crushing: Used for the fine crushing stage of metal ores such as iron ore, copper ore, and gold ore, creating favorable conditions for subsequent grinding.

• Building Material Processing: Shaping building stone to obtain high-value, uniformly sized, high-quality aggregates.

• Pre-crushing for Industrial Powder Making: High-efficiency pre-crushing in the deep processing of non-metallic minerals (such as calcium carbonate and quartz sand).

• Tailings and Construction Waste Recycling: Achieving refined crushing and recycling of solid waste resources, contributing to a green circular economy.

Global Project Cases Demonstrate Our Strength

Our equipment has served more than 50 countries and regions worldwide. Below are some typical examples:

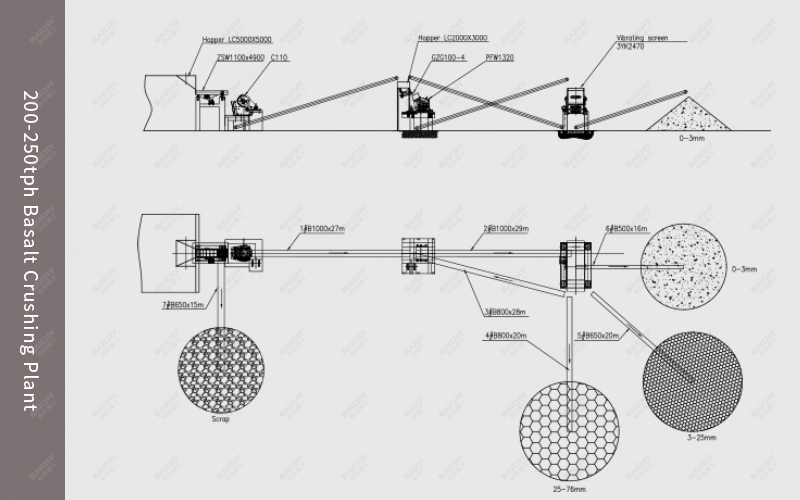

• Southeast Asia Large-Scale Granite Sand Making Project: Using a VSI-1140 vertical shaft impact crusher as the core of the sand making process, 25-40mm crushed stone is processed into 0-5mm high-quality manufactured sand, producing over 1500 tons of high-quality sand per day. The product has a rounded particle shape and gradation that fully meets national standards, helping the client successfully enter the local high-end building materials market.

• African Copper Mine Beneficiation Plant Fine Crushing Upgrade Project: Replacing the old cone crusher for tertiary fine crushing of copper ore. With a feed particle size ≤40mm and an output P80 below 8mm, the system significantly improves the processing capacity of subsequent ball mills, increasing overall system capacity by approximately 20% and reducing energy consumption by 15%, earning high praise from customers.

• Construction Waste Resource Utilization Center in East China: Utilizing a mobile vertical shaft impact crusher and screening unit, the system crushes, screens, and shapes demolition waste on-site, producing high-quality recycled aggregates widely used in roadbed filling and low-grade concrete, achieving significant environmental and economic benefits.

Frequently Asked Questions (FAQ)

Q1: What are the main differences between vertical shaft impact crushers, cone crushers, and impact crushers in fine crushing applications?

A1: Cone crushers rely on layered crushing and are more suitable for coarse and medium crushing of medium-hard and harder materials, but the product particle shape is generally average. Impact crushers utilize impact energy and are suitable for medium-soft materials, producing better particle shape. Vertical shaft impact crushers utilize high-speed centrifugal force to cause materials to collide with or impact wear-resistant anvils, combining crushing and shaping functions. They are particularly suitable for producing fine materials with excellent particle shape and uniform particle size (such as manufactured sand), making them the preferred choice for shaping and sand making.

Q2: What is the lifespan of the key wear parts of the equipment? Is replacement complicated?

A2: Core wear parts such as the throwing head, peripheral guard plates, and persion cones all adopt a modular design and high wear-resistant composite materials, resulting in a long service life. Taking granite processing as an example, the normal service life of the throwing head can reach 300-600 hours. Our design standardizes the replacement process, and with the assistance of specialized tools, the replacement of major wear parts can be completed within a few hours, minimizing downtime.

Q3: Does it support customized configurations to adapt to specific mineral properties?

A3: Of course. We offer in-depth customization services, tailoring our rotor structure, speed, crushing chamber type, and wear-resistant component materials to your specific material properties (such as hardness, moisture content, and silicon content), target product particle size distribution, production capacity requirements, and installation site limitations. This ensures the equipment performs optimally under your operating conditions.

Q4: What special environmental features are included?

A4: The equipment employs a fully enclosed structure, effectively suppressing dust escape. It can be easily connected to external dust collection systems. Simultaneously, the optimized flow channel design and internal airflow circulation reduce dust generation points. Low-noise design and a robust vibration-damping foundation also help customers meet stringent environmental and occupational health standards.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.