1.Equipment introduction

PE jaw crusher is a kind of stone crushing equipment widely used for coarse crushing and medium crushing of various materials with compressive strength below 320 MPa, it is usually used as primary crushing equipment, and its popular models are PE400×600 jaw crusher, PE500×750 jaw crusher, PE600×900 jaw crusher, PE750×1060 jaw crusher, PE900×1200 jaw crusher, etc.

| Model | Max. Feeding Size (mm) |

Outlet adjusting Size(mm) |

Capacity (t/h) |

Motor Power (kw) |

Overall Dimension (mm) |

|---|---|---|---|---|---|

| PE400x600 | 350 | 40-90 | 15-60 | 30 | 1700x1750x1680 |

2.Applied material

Jaw crusher can be widely used in quarry, metallurgy, construction, cement, chemical industry and other industries. In quarries, it is usually used to break stone, limestone, granite, marble and other ores; In metallurgy, construction, cement and other industries, it is used to break materials with higher hardness, such as coal ash, limestone, iron ore and so on. In addition, jaw crusher can also be used to break some special materials, such as cellulose board, concrete blocks from old buildings, steel scrap and so on. In the field of environmental protection, jaw breakers can be used to recycle and dispose of waste, reducing the impact on the environment.

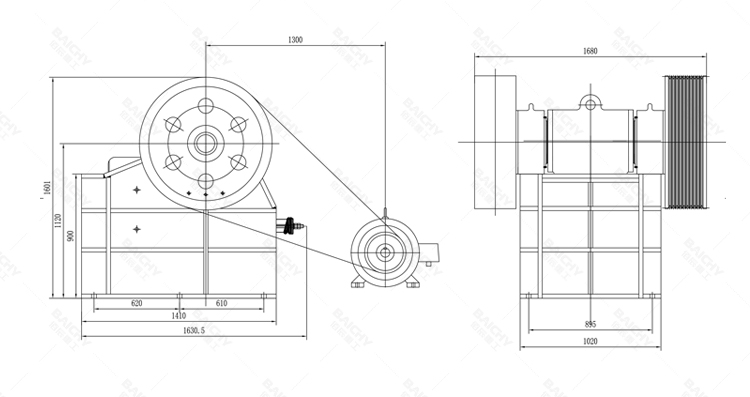

3.Equipment structure

Jaw crusher is mainly composed of body, eccentric shaft, fixed jaw plate, moving jaw plate, adjusting device, transmission device, power part and so on.

4.Working principle

The electromotor drives the belt and the pulley to make the movable jaw move back and force, up and down through the eccentric shaft. The raw material is squashed or split when the movable jaw plate moves towards the fixed jaw plate. When movable jaw plate turns back by eccentric shaft, spring and pull rod, the raw material, which is squashed or split before discharges from the bottom outlet under jaw plate. The bulk-production comes true while electromotor rotates continuously and the movable jaw crushes and discharges the raw material periodically.

5.Equipment advantage

PE jaw crusher has many advantages, such as large crushing ratio, uniform discharge particle size, and large discharge port adjustment range can meet the needs of different customers. In the later work, the machine lubrication system is safe and reliable, the replacement of spare parts is simple and convenient, and the maintenance workload is small. Another feature is that the equipment structure is simple, which can reduce operating costs.

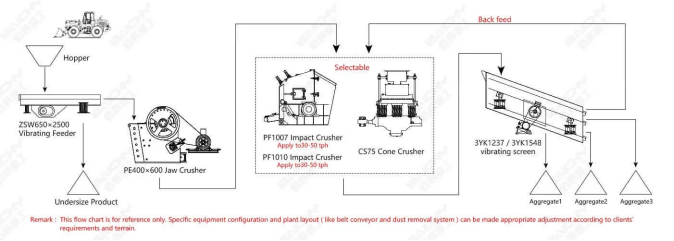

6.Production line

The equipment can be used for 40-60 tph stone crushing production line, it can be matched with ZSW650×2500 vibrating feeder, secondary crushing equipment like PFW1007 / PFW1007 impact crusher / CS75B cone crusher, 3YK1237 / 3YK1548 vibrating screen, return belt and other equipment for production. And this is for reference only, specific equipment configuration and plant layout (like belt conveyor and dust removal system) can be appropriately adjusted according to the requirements of our users.

7.Production line fit object

PE400×600 jaw crusher can break a variety of stone, such as granite, marble, bluestone, quartz, dolomite, pebbles, slag, steel slag, construction waste, bricks and other more than 100 kinds of materials, so its high applicability, general stone can be used to break, but the crusher's output is not high, the maximum can reach 60 tons per hour, therefore, it is very popular in small and medium-sized sand and stone factories. In the second place, this machine is light in weight, easy to use, occupies a relatively small area, so the equipment is strong in adaptability. It is also highly important to point out that PE400×600 jaw crusher power is low, so the energy saving effect is good, which can effectively reduce the operation cost, reduce the burden of your enterprise, and it can also help you save the early investment, quick return.

If you need a smaller or larger output of jaw breaking machine, or do not know whether your sand and stone factory can use this model in the end, you can directly consult technicians online to tailor the type selection or customized model for you to meet your production needs.

8.Portable crushing plant

PE400×600 jaw crusher is often used in simple mobile station, mainly for small mine crushing systems with low cost investment. This mobile crusher is suitable for dealing with all kinds of rock, concrete and other hard stone, it is regarded as the combination of feeding and crushing in mobile crushing equipment, and it is composed of vibrating feeder, jaw crusher, belt conveyor, power system and chassis.

With convenient and strong mobility, the simple portable crushing plant can save a lot of infrastructure and relocation costs. It can crush materials on-site and move around to different places according to your needs. It has greatly reduced the material transport cost.