Light Expanded Clay Aggregate(LECA) Ceramsite Production Line

In today's global wave of environmentally friendly building materials and green building, Lightweight Expanded Clay Aggregate (LECA), as a high-performance new building material, is poised to take center stage in the market. The core behind it the LECA expanded clay aggregate production line is not only a testament to technological strength but also a potential gold mine.

As a manufacturer with decades of experience in the mining machinery industry, we will provide you with an in-depth analysis of how to build a highly competitive LECA expanded clay aggregate production line, helping you seize the high ground in the new materials field.

I. LECA Expanded Clay Aggregate: Small Particles, Big Market

LECA is a lightweight, porous aggregate made from raw materials such as expanded clay, shale, or sludge through high-temperature calcination. Why is it so popular?

• Lightweight and High-Strength: Significantly reduces the self-weight of buildings, saving on structural and foundation costs.

• Thermal Insulation: Excellent thermal insulation performance, making it an ideal choice for green and energy-efficient buildings.

• Fireproof and Corrosion-Resistant: Class A fire resistance, excellent durability.

• Environmentally Friendly and Waste-Utilizing: It can absorb large amounts of river silt, shale, and even some industrial waste, aligning with the national policy of a circular economy.

Applications range from lightweight concrete aggregates and roof insulation slope finding to hydroponics and water conservancy greening, with an extremely broad market prospect. Investing in a LECA production line is a crucial step into this blue ocean market.

II. Core Components and Technological Essence of a Top-Tier LECA Ceramsite Production Line

A mature production line is far more than a simple collection of equipment; it is a sophisticated system with interconnected stages. Its main sections include:

1. Raw Material Pretreatment and Homogenization Section: This is the lifeline of quality. Our core equipment includes jaw crushers, roller pelletizers, and twin-shaft mixers, ensuring that the raw materials are crushed, mixed, and homogenized to their optimal plasticity, laying the foundation for subsequent pelletizing and expansion.

2. Aging and Molding Section: After homogenization, the raw materials enter the aging silo for further conditioning, enhancing their plasticity. Subsequently, using an advanced two-stage mixing extruder or roller pelletizer, raw material pellets with uniform specifications and high density are produced. The uniformity of the pellets directly determines the final grade of the ceramsite.

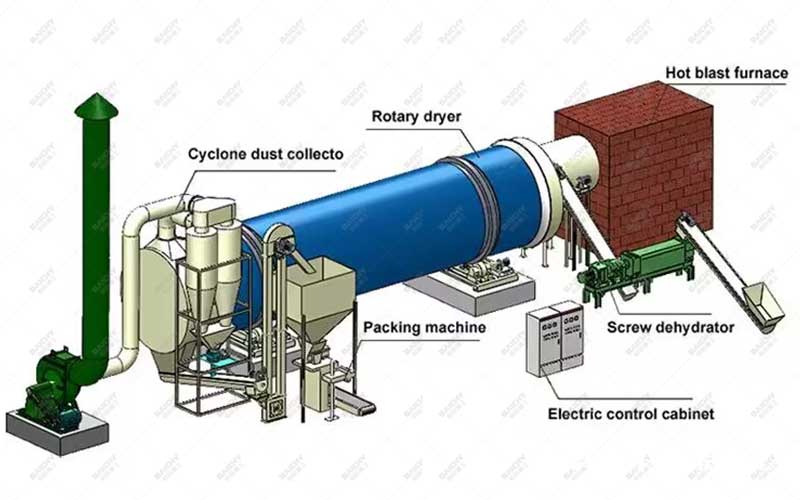

3. Drying and Preheating Section: Wet raw material pellets have low strength and must pass through a single-layer drum screen drying and preheating equipment to gradually remove moisture and increase strength to withstand the subsequent high-temperature impact.

4. Calcination and Cooling Section: This is the soul of the entire production line. The raw material pellets undergo calcination at temperatures as high as 1100-1200℃ in a rotary kiln. At this temperature, the clay melts, and the gas expands, forming an internal porous structure. Our intelligent rotary kiln can precisely control the temperature, ensuring maximum expansion rate and minimum energy consumption. Subsequently, the ceramsite enters a cooler for rapid cooling, locking in the microstructure.

5. Screening and Packaging Section: The cooled ceramsite is graded by particle size (e.g., 0-5mm, 5-10mm, etc.) through a multi-layer high-efficiency vibrating screen, and finally packaged and stored as a commercial product.

III. Why Choose Us as Your Strategic Partner?

You're not just purchasing equipment, but a complete solution and a guarantee of long-term profitability. Our advantages include:

• Turnkey Project Management Capabilities: From project planning, process design, equipment manufacturing and installation, commissioning to personnel training, we provide one-stop service, saving you time and effort.

• Independent R&D and Optimization of Core Equipment: Especially in key processes such as crushing, homogenization, pelletizing, and calcination, our equipment has significant advantages in efficiency, energy consumption, and durability.

• Intelligent Control System: Integrating PLC and online monitoring, we achieve visualized monitoring and intelligent adjustment of the entire production line, significantly reducing reliance on operators and improving product stability.

• Full Lifecycle Service: We provide ample spare parts support and rapid-response technical maintenance to ensure the long-term stable operation of your production line and maximize your return on investment.

Investing in a LECA expanded clay aggregate production line is a wise move to keep pace with the green building era. Partnering with a seasoned partner who understands technology, the market, and your needs will be key to project success. We cordially invite you to visit and inspect our facilities, and together we can discuss how to tailor a high-efficiency, energy-saving, and high-return LECA ceramsite production line for you, and jointly create a new chapter in our business.