In many industrial sectors, the particle size of powder materials often determines the performance and value of the final product. When processing requires ultrafine particles of 800 mesh (approximately 15-20 micrometers), a high-efficiency and stable ultrafine grinding mill becomes the core of the production line. So, how do you choose a suitable 800-mesh mill? What breakthroughs can it bring to your business? This article will provide a comprehensive analysis.

I. Why is 800-mesh particle size so important?

Powders around 800 mesh fall into the micrometer-level category. Materials of this particle size have a larger specific surface area and higher reactivity, thus significantly improving product performance. For example:

• Coatings and paints: Makes pigment distribution more uniform, colors brighter, and hiding power stronger.

• Plastics and rubber: As a filler, it enhances product strength, toughness, and smoothness.

• Pharmaceuticals and food: Improves the bioavailability and mixing uniformity of raw materials.

• High-end ceramics: Makes the body structure denser, resulting in superior performance after sintering.

Therefore, investing in a reliable 800-mesh ultrafine grinding equipment is a crucial step in enhancing product added value and entering the high-end market.

II. How does an 800-mesh ultrafine grinding mill work?

Common grinding mills capable of achieving 800-mesh fineness fall into the following categories, each with its own unique working principle:

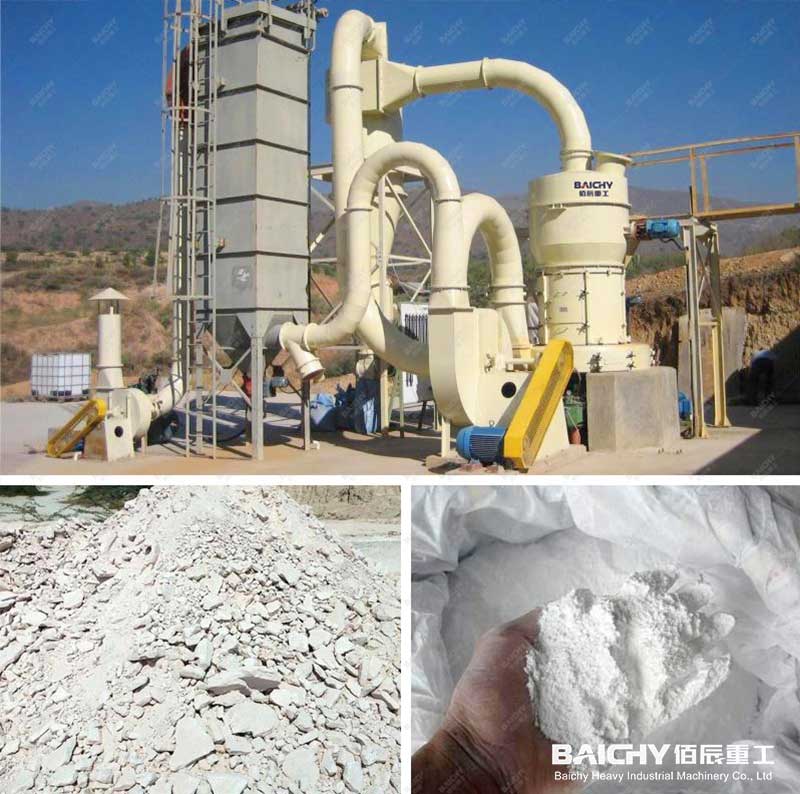

1. Vertical Grinding Mill: This is a typical example of a high-efficiency, energy-saving 800-mesh grinding mill that we recommend. It uses a grinding roller to crush materials, resulting in low energy consumption, high output, and low noise. It is particularly suitable for large-scale production of non-metallic minerals (such as calcium carbonate, talc, and barite).

2. Airflow Mill: This uses high-speed airflow to pulverize materials by causing collisions between particles. This is currently one of the most mainstream ultrafine grinding solutions, especially suitable for pulverizing high-hardness, high-purity, and heat-sensitive materials. The pulverization fineness can easily reach over 800 mesh, and the product purity is extremely high.

3. Vibratory Mill: This uses high-frequency vibration of grinding media (balls or rods) to impact and grind materials. Suitable for small-batch, multi-variety fine processing.

III. How to Choose the Right 800-Mesh Mill for You? — A Practical Selection Guide

When faced with differences in 800-mesh mill prices, you need to consider the following aspects comprehensively, rather than just focusing on the equipment price:

• Material Properties: Hardness, moisture content, viscosity, and heat resistance are primary factors to consider. For example, high-hardness materials are more suitable for air jet mills or vibratory mills.

• Capacity Requirements: Is it for experimental research and development or large-scale production? This directly determines the equipment model and investment scale.

• Particle Size Distribution Requirements: Is strict particle size control and pollution-free processing required? Air jet mills excel in this regard.

• Investment and Operating Costs: Although the initial purchase cost of a vertical mill may be higher, its low energy consumption significantly reduces long-term operating costs.

IV. Advantages of Our 800-Mesh Ultrafine Grinding Solution

Our multi-functional 800-mesh fine grinding mill integrates multiple advanced technologies, ensuring a stable and reliable micron-level grinding solution for you:

• Precise and Controllable Particle Size: Utilizing a high-efficiency grading system, it ensures that over 99% of the finished product passes through 800 mesh, with a concentrated particle size distribution and no large particles.

• High Efficiency, Energy Saving, and Environmental Protection: Compared to traditional equipment, energy consumption is reduced by up to 30%, and it is equipped with a pulse dust removal system for green production.

• Wear-Resistant Core Components: Key components such as grinding rollers and grinding rings are made of highly wear-resistant materials, resulting in a long service life and low maintenance costs.

• Wide Range of Applications: The equipment is suitable for numerous industries including chemical, pharmaceutical, food, mining, and new materials, providing a strong guarantee for your powder technology upgrade.

Choosing a suitable 800-mesh ultrafine grinding mill is a strategic investment to enhance your company's core competitiveness. We are not only an 800-mesh grinding mill equipment manufacturer, but also your trustworthy powder technology partner. If you are facing a bottleneck in powder fineness, please feel free to contact us. Our technical engineers will provide you with a customized 800-mesh pulverization solution and the most competitive equipment quote based on your specific material and production capacity requirements.