In the sand and gravel aggregate and mining industry, selecting efficient and reliable production equipment is crucial to the success of an investment. For large-scale stone quarries and mining projects pursuing large-scale, continuous, and low-cost operations, stationary crushing and screening production lines are undoubtedly the ultimate solution to achieve this goal. This article will provide you with a comprehensive understanding of all aspects of stationary crushing and screening systems.

I. What is a Stationary Crushing and Screening Production Line?

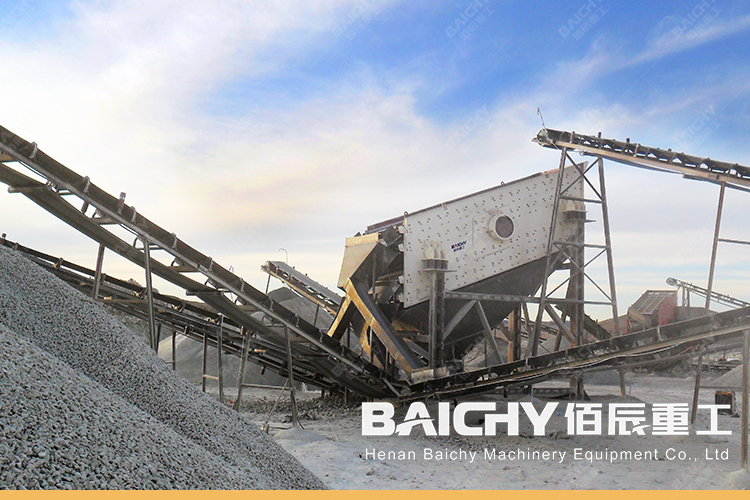

A stationary crushing and screening production line refers to a complete production system where all main equipment (such as feeders, crushers, screening machines, conveyors, etc.) is fixedly installed at a specific work site. It is typically planned and constructed around the raw material extraction point or quarry, forming a coherent crushing-screening-conveying closed loop, specifically designed for processing high-hardness, high-volume raw materials (such as granite, basalt, limestone, etc.).

II. Core Advantages of Stationary Production Lines: Why is it the cornerstone of long-term investment?

Compared to mobile crushing plants, stationary production lines offer irreplaceable advantages in specific scenarios:

1. Unparalleled stability and high capacity: The robust foundation allows the equipment to withstand continuous, high-intensity vibration and loads, enabling 24/7 continuous operation. A single line can achieve a capacity of hundreds to thousands of tons per hour, meeting the aggregate needs of large-scale projects.

2. Superior finished product quality and economic benefits: The system can employ multi-stage crushing (coarse, medium, and fine crushing) and fine screening processes, combined with specialized equipment such as jaw crushers and cone crushers, resulting in superior aggregate particle shape and reasonable gradation, leading to higher market value.

3. Lower long-term operating costs: Although initial civil engineering investment is higher, the equipment boasts high efficiency and relatively low energy consumption. Furthermore, the core crushers (such as cone crushers) have long wear-resistant parts and a low failure rate. From a life-cycle perspective, the overall operating cost is significantly lower than that of mobile plants.

4. Highly Automated and Intelligent Control: The entire production line can be started and stopped with a single button, monitored online, and alarmed for faults through a central control system, significantly reducing reliance on manual labor and improving production safety and management efficiency.

III. How is a Typical Production Line Configured?

A highly efficient stationary crushing and screening production line is the result of a customized solution. A typical configuration is as follows:

• First Stage: Coarse Crushing - Jaw Crusher

◦ Task: Performs the first crushing of large pieces of raw stone (rough material), serving as the choke point of the production line.

◦ Key Equipment: Large, deep-cavity jaw crusher, renowned for its powerful crushing force and high reliability.

• Second Stage: Medium Crushing - Cone Crusher or Impact Crusher

◦ Task: Performs secondary crushing of the coarsely crushed stone, also serving a shaping function.

◦ Key Equipment: For high-hardness rocks, a cone crusher is preferred, offering layered crushing and good wear resistance; for medium-hardness rocks, an impact crusher can be selected, resulting in a better finished particle shape.

• Third Stage: Screening and Fine Crushing - Vibrating Screen and Sand Making Machine

◦ Task: To screen stone into finished products of different specifications (e.g., 0-5mm, 5-10mm, 10-20mm, etc.) using a multi-layer vibrating screen. Materials that do not meet the requirements are returned to the impact crusher (fine crusher) for third-stage crushing, forming a closed-loop cycle to ensure maximum resource utilization.

IV. Is a Stationary Production Line Suitable for Your Project?

If you meet the following conditions, a stationary crushing and screening solution will be your best choice:

• Large Project Scale: Annual output typically exceeds one million tons, with a service life exceeding 5-8 years.

• Fixed Raw Material Characteristics: Concentrated mineral resources and relatively simple raw material types.

• High Requirements for Finished Product Quality: Requires stable, multi-specification, and high-quality aggregates with excellent particle shape.

• Pursuit of Long-Term Return on Investment: Focus on the total life cycle cost of equipment, rather than just the initial investment.

Stationary crushing and screening production lines are not only the production heart of large-scale stone quarries and mining projects, but also a solid guarantee for their long-term stable profitability. They represent the direction of large-scale, professional, and modernized production.

Baichy Heavy Industry has been deeply involved in the mining machinery field for decades. We not only provide a full range of high-performance, high-reliability equipment such as jaw crushers, cone crushers, and vibrating screens, but also scientifically plan and tailor the optimal overall stationary crushing and screening solution according to your site conditions, raw material characteristics, and finished product requirements, providing full-cycle technical support from installation and commissioning to operation and maintenance.

Contact us now to get a free, customized production line design plan and equipment quotation, giving your project a head start!