A 100-ton/hour stone production line is the ideal configuration for medium to large-scale sand and gravel aggregate projects. The choice of the "heart" of the production line—the crushing equipment—directly determines the efficiency, finished product quality, and return on investment of the entire line.

This article will delve into the key role of 100-ton/hour crushers, analyze the applicable scenarios for different crushing equipment, and provide a comprehensive selection guide to help you build an efficient and profitable large-scale stone production system.

Why is 100 tons/hour a watershed moment for large-scale operations?

In the sand and gravel aggregate industry, a 100-ton/hour capacity marks the transition of a project from small to large-scale, industrialized operations. This capacity effectively balances the continuous and stable raw material demands of large clients such as infrastructure construction projects and commercial concrete plants with the company's initial investment costs. Therefore, choosing a stable, efficient, and adaptable 100-ton/hour crusher becomes the cornerstone of project success. It is not only the executor of the crushing process but also the "metronome" coordinating subsequent processes such as feeding, screening, and conveying; its performance directly affects the smooth operation of the entire production line.

I. The Key Role of a 100-ton/hour Crusher in the Production Line

As core equipment, the 100-ton/hour crusher undertakes the following key missions:

1. Determining the Maximum Capacity: The production line's designed capacity is based on the throughput capacity of the main crusher. A stable 100-ton/hour crusher is the minimum requirement to ensure the production line reaches its designed capacity.

2. Affecting Finished Product Quality and Particle Shape: The crusher's operating principle (e.g., cone crusher for layered crushing or impact crusher for impact crushing) directly determines the particle shape (cubic content), needle-like and flaky content, and internal cracks of the finished aggregate. These are key indicators for evaluating aggregate quality and price.

3. Dominating Operating Costs: The equipment's energy consumption, wear resistance, and replacement cycle of vulnerable parts (e.g., jaw plates, mantles, hammers) constitute the main components of daily operating costs. A well-designed piece of equipment can significantly reduce the cost per ton.

4. Influencing Overall Line Configuration: The type of main crusher determines the size of the front-end feeder, the area and screen configuration of the rear-end screening machine, and the scale of the dust removal system, serving as the starting point for process design.

II. Comparison and Selection of Common 100-ton/hour Crusher Types

There is no "one-size-fits-all" crusher, only the most suitable solution for specific working conditions and raw materials. Below is a comparison of three core pieces of equipment commonly used to achieve a 100-ton/hour capacity:

| Equipment Type | Core Advantages | Applicable Scenarios and Raw Materials |

| Jaw Crusher (for coarse crushing) | Simple structure, robust and durable, large feed opening, and strong processing capacity; the absolute mainstay of primary crushing. Suitable for primary crushing of high-hardness materials (such as granite and basalt). | Usually used as the first crushing stage in a production line. Finished product particle shape is generally average, with a high content of needle-like and flaky particles; usually needs to be used in conjunction with medium crushing equipment. |

| Cone Crusher (for medium/fine crushing) | Employs the principle of layered crushing, with long wear-resistant parts life and relatively low energy consumption; suitable for secondary crushing of medium to high-hardness materials. The first choice for crushing high-hardness materials; produces good finished product particle shape and is easy to control discharge particle size. |

Higher equipment purchase cost, relatively complex structure, and maintenance requires a certain level of expertise. |

| Impact crushers | (used for medium/fine crushing) employ the principle of impact crushing, producing excellent finished product particle shape (mostly cubic) and a large crushing ratio. The finished product size can be changed by adjusting the rotor speed. | They are ideal for medium-to-low hardness materials (such as limestone) and are commonly used equipment for producing high-quality manufactured sand. However, the wear parts (hammer plates) wear relatively quickly, costs surge when processing high-hardness materials, and dust is generated significantly. |

Selection Decision Path Reference:

• High raw material hardness (such as granite): Jaw crusher (coarse crushing) + Cone crusher (medium-fine crushing). This combination excels in wear resistance and stability, making it a classic solution for high-standard aggregate production.

• Medium-to-low raw material hardness (such as limestone): Jaw crusher (coarse crushing) + Impact crusher (medium-fine crushing). This combination ensures sufficient capacity while obtaining better finished product particle shape, resulting in significant economic benefits.

III. Beyond the Equipment Itself: A Systematic Approach to Building an Efficient Production Line

Selecting a 100-ton/hour crusher requires more than just looking at inpidual machine parameters; a systematic perspective is essential:

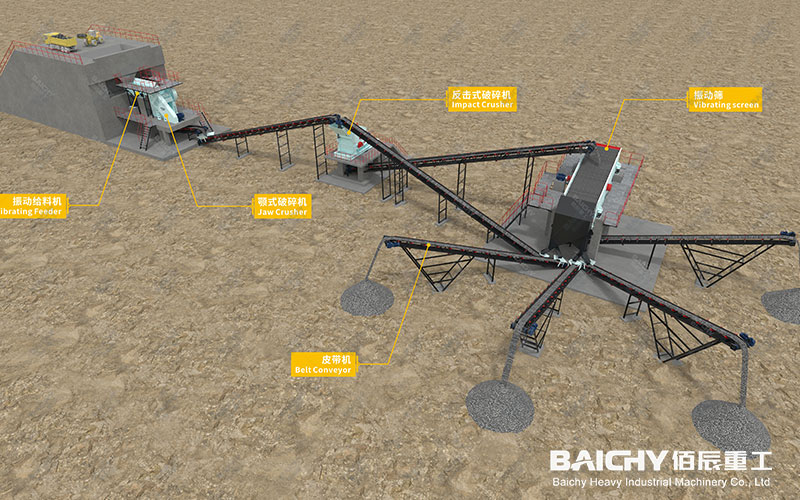

• Synergy of Feeding-Crushing-Screening: Ensure the feeder provides uniform and continuous feed, preventing the crusher from being underfed or overloaded. Efficient screening by the screening machine reduces over-crushing and increases effective capacity.

• Environmental and Intelligent Standards: Large production lines must be equipped with efficient pulse-jet bag filters and sealed conveyor systems. Simultaneously, consider adding an online equipment status monitoring system to enable predictive maintenance and minimize downtime.

• Long-Term Return on Investment Analysis: When purchasing, don't just compare the unit price of the equipment; calculate the cost per ton (equipment depreciation + energy consumption + wear parts consumption + maintenance labor) / total output. A slightly more expensive but energy-efficient and wear-resistant machine typically offers a higher long-term return.

Conclusion: Wise Selection is Half the Battle

Investing in a 100-ton/hour stone production line is a significant decision. Among these factors, the selection of core crushing equipment is of paramount importance. It's not just about purchasing a machine; it's about laying the foundation for your production and profit model for the next 5 to 10 years. We strongly recommend that you provide detailed information on raw material properties, expected finished product specifications, and site conditions, and engage in in-depth communication with professional equipment suppliers to obtain customized solutions, not just product quotes.

Action Recommendation: If you are planning or upgrading your stone production line and have questions about selecting a 100-ton/hour crushing unit, please feel free to contact the technical expert team at [Your Brand Name]. With extensive project experience, we can provide you with free on-site material testing and customized production line process design solutions, using our expertise to help you make the wisest investment decisions.