Double Roll Crushers in Sand and Gravel Production

Sand and gravel, as the staple for infrastructure construction such as buildings, roads, and bridges, have production efficiency and finished product quality that directly impact project costs and final quality. Among numerous crushing equipment, the double-roll crusher (also known as the twin-roll crusher), with its unique structure and performance, plays an indispensable role in specific sand and gravel production processes.

With increasingly stringent environmental policies and higher market demands for sand and gravel particle shape and gradation, the traditional extensive crushing mode is gradually being replaced by refined and efficient production processes. The double-roll crusher, as a medium and fine crushing equipment, crushes materials through the squeezing and grinding forces generated by the counter-rotating rollers, and is particularly suitable for producing manufactured sand and high-quality aggregates of small and medium particle sizes. It demonstrates unique economic and practical advantages over other crushing equipment when processing materials of medium hardness or less (such as river pebbles, limestone, and weathered sand).

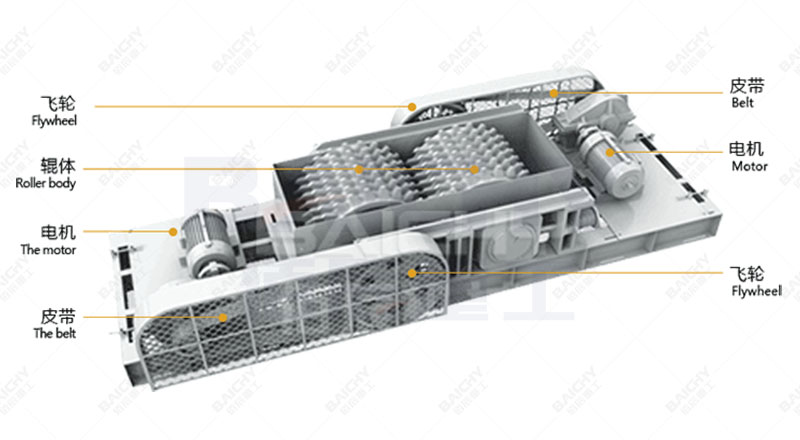

Structure diagram of a double-roll crusher

Simple and Reliable Crushing Principle

The structure of the double-roll crusher mainly consists of a frame, a pair of rollers, a transmission device (motor, pulleys, gears), and a spring or hydraulic adjustment device. Its working principle is intuitive and efficient: the two rollers rotate in opposite directions, and the material to be crushed falls from the top feed opening. Under the action of friction and gravity, it is drawn into the V-shaped crushing chamber between the two rollers, where it is continuously subjected to high-pressure squeezing and shearing forces. The particle size of the crushed product can be precisely controlled by adjusting the gap between the two rollers. This principle inherently gives it the characteristics of a simple structure, less over-crushing, and uniform finished product particle size.

Roller sand making machine for crushing and sand making

Why is it irreplaceable in sand and gravel production?

Based on our 20 years of equipment manufacturing and customer feedback, the double-roll crusher has the following five major advantages in sand and gravel production:

1. Excellent finished product particle shape and controllable gradation

The principle of compression crushing causes the material to break more along its natural cleavage planes, resulting in cubic or polyhedral particles with extremely low needle-like and flaky content. This particle shape is what is sought after for high-quality manufactured sand and high-standard concrete aggregates, effectively improving the workability and strength of concrete. By adjusting the roller gap, the output particle size can be easily controlled to meet different gradation requirements.

2. Low over-crushing rate, easy control of fines content

Compared with equipment that primarily uses impact crushing (such as impact crushers), the crushing process of double-roll crushers is more gentle. The material is not subjected to excessive impact and grinding, so the content of stone powder (<0.075mm) produced is relatively low and more stable. This is a significant advantage for commercial concrete plants and dry-mix mortar sand producers that require strict control of stone powder content.

3. Simple structure, convenient maintenance, and low operating costs

Its mechanical structure is relatively simple, with fewer failure points. The main wear parts are the roller shells (roller surfaces), which are very easy to replace. The daily maintenance workload is small, greatly reducing the long-term operating costs and downtime of the equipment, which is crucial for sand and gravel plants that pursue continuous and stable production.

4. Good adaptability to wet materials and strong anti-clogging ability

When crushing materials with high moisture content, double-roll crushers are less prone to clogging than jaw crushers and cone crushers. Its continuous squeezing action can effectively handle slightly sticky soil and stone mixtures, and in some applications where the raw material requirements are not so stringent, it can eliminate the need for pre-drying.

5. Energy-saving and environmentally friendly, with low noise and dust emissions

Due to its efficient and direct crushing method, the energy is mainly used for the crushing of the material itself, with less wasted energy consumption, so the energy consumption per ton is relatively low. At the same time, the airflow disturbance generated during the squeezing process is small, and there are fewer dust sources. With simple sealing and dust removal devices, a good environmental protection effect can be achieved, and the working noise is also relatively low.

Double-roll crusher customer site

Actual Application Case

In a project at a large green building materials industrial park in East China, we configured a limestone sand production line with a capacity of 500 tons per hour for our customer. The key medium and fine crushing and shaping processes used our large hydraulic adjustable double-roll crusher.

• Challenge: The customer required the final manufactured sand to have a perfect particle shape (high proportion of cubic particles), and the stone powder content needed to be stably controlled between 5% and 10% to meet the needs of high-end concrete.

• Solution: The limestone (≤50mm) after coarse crushing by a jaw crusher was directly fed into our double-roll crusher for closed-circuit crushing and shaping. • Effect: The finished sand particles are round and polyhedral in shape, with continuous gradation, and the stone powder content is stably maintained at around 8%, fully meeting customer requirements. After two years of operation, the maintenance cost of the equipment is only 60% of that of other main crushing equipment in the production line. The customer highly praised its stability and economic efficiency.

Related Equipment Recommendations and Selection Suggestions

Double-roll crushers are not universally applicable; their optimal feed size usually does not exceed 30-50mm. Therefore, they are typically used as secondary or tertiary crushing (fine crushing, shaping) equipment in a production line. For an efficient sand and gravel production line, we recommend the following combination:

| Coarse crushing | Jaw crusher (for processing large raw materials) |

| Medium and fine crushing | Choose a cone crusher (for high-hardness materials) or an impact crusher (for medium-hardness materials, focusing on output). |

| Fine crushing, shaping, and sand making | Double-roll crusher (for optimal particle shape and controllable powder content) or impact sand making machine (for high output and adjustable fineness modulus). |

Selection Suggestions: When choosing a double-roll crusher, please focus on the roller surface material (high-manganese steel, wear-resistant alloy, etc.), adjustment method (mechanical spring or hydraulic, hydraulic is more precise and convenient), and driving power. Be sure to consult a professional manufacturer for solution design based on your raw material characteristics (hardness, humidity, clay content) and target product requirements.

VI. Frequently Asked Questions (FAQ)

Q1: Can double-roll crushers process high-hardness materials such as granite and basalt?

A1: Yes, but it is not economical. Processing high-hardness materials will drastically accelerate roller wear, significantly increasing operating costs. It is more suitable for medium-to-low hardness materials (compressive strength ≤160MPa), such as limestone, marl, slag, coal, clay, etc.

Q2: What are the main differences between double-roll crushers and impact sand making machines in sand making?

A2: Double-roll crushers mainly use extrusion crushing, resulting in good finished particle shape, stable gradation, and controllable powder content, but the processing capacity is relatively small, making it more suitable for high-quality sand production. Impact crushers primarily utilize stone-on-stone or stone-on-metal impact crushing, offering high output and flexible adjustment. However, the finished product tends to have a slightly higher proportion of flaky particles and a higher content of stone powder.

Q3: How is the uniform particle size of the output guaranteed?

A3: This is mainly achieved by ensuring the parallelism of the two rollers and uniform wear of the roller surfaces. Modern hydraulically adjusted double-roll crushers are equipped with an automatic compensation function. When the roller surface wears down, the hydraulic system automatically pushes the rollers to maintain the set gap, thus stabilizing the output particle size over a longer period.

Q4: What special designs does your double-roll crusher have in terms of wear resistance?

A4: Based on 20 years of experience, we offer a variety of replaceable roller shells, including standard high-manganese steel, hardfacing wear-resistant alloys, and composite tungsten carbide alloy roller sleeves suitable for extremely harsh working conditions. At the same time, our innovative roller surface structure design ensures uniform wear of the material on the roller surface, extending the service life by at least 30%.

In summary, the double-roll crusher is one of the ideal choices for sand and gravel production seeking high-quality finished products, controlled operating costs, and green production. We hope our 20 years of professional insights can help you better plan and optimize your production line. For further technical consultation or customized solutions, please feel free to contact us.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.