European-Style Impact Crusher Technology Solution

In the field of mining crushing, the choice of technical route directly determines production efficiency, product quality, and operating costs. As a mining crushing equipment manufacturer with 20 years of professional experience, we deeply understand that traditional crushing solutions can no longer meet the market's demand for high-specification aggregates and refined production. Against this backdrop, the European-style impact crusher technology solution, with its superior design philosophy and technical advantages, is leading the innovation trend in medium and fine crushing operations. This article will delve into this technical solution, revealing its core value as an industry benchmark.

| Key Words | Mobile Impact Crusher | Crushing Machines |

|---|---|

| Product Model | Impact Crusher |

| Feed Size | ≤400mm |

| Motor Power | 45-315kw |

| Capacity | 10-400 t/h |

| Core Advantages | High efficiency and energy saving, excellent particle shape, flexible adjustment, and simultaneous shaping capabilities. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

What is the European-style Impact Crusher technology solution?

The European-style impact crusher is not simply a geographical concept; it represents a complete technical system derived from advanced European engineering design concepts. Compared to ordinary impact crushers, its core lies in the deep integration of structural innovation, materials science application, and dynamic optimization. This solution typically employs a keyless heavy-duty rotor design, a hydraulic opening device, wear-resistant composite material hammer plates, and a smoother cavity curve. Its goal is to improve the crushing ratio and output while achieving more precise control over the shape and size distribution of the output material, making it particularly suitable for producing high-quality cubic aggregates used in high-grade construction and road building.

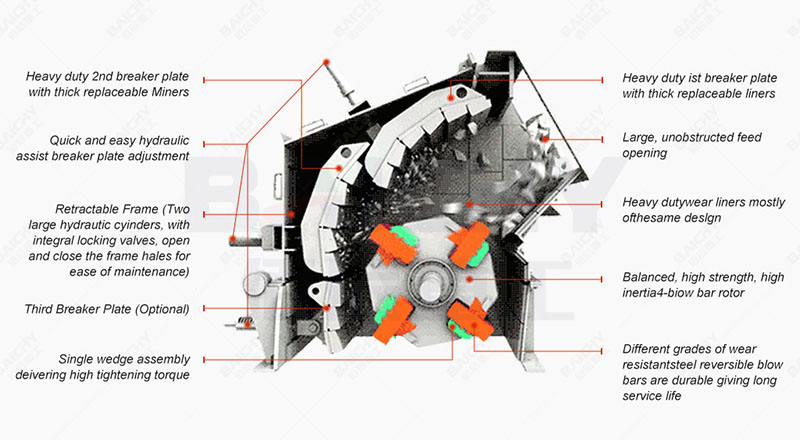

Overview of Core Design Highlights

Our European-style impact crusher technology solution embodies twenty years of manufacturing experience and cutting-edge international technology. Its main highlights include:

1. Heavy-duty Rotor Structure: Adopting a high-inertia, keyless integrated rotor or a split-type welded rotor, it offers greater rotational inertia, stronger crushing force, and more stable operation, especially suitable for processing hard materials.

2. Hydraulic Adjustment and Maintenance System: Equipped with a hydraulically assisted frame opening device, it makes maintenance work such as hammer plate replacement and liner inspection safe and fast, significantly reducing downtime.

3. Three-chamber/Two-chamber Optimized Design: Through a finely designed crushing chamber, it provides multiple impact and grinding opportunities for the material, ensuring higher crushing efficiency and better particle shape, resulting in cubic products with low needle-like and flaky content.

4. High-Performance Wear-Resistant Components: The composite cast hammerheads and liners, made with alloy elements such as chromium, molybdenum, and nickel, significantly improve wear resistance and impact toughness, extending service life and reducing per-ton cost.

PF Impact Crusher Structure Diagram

Core Advantages: Creating Real Value for Customers

Choosing our European-style impact crusher technology solution means guaranteed benefits in the following areas:

• Excellent Product Particle Shape: The produced aggregate has a good cubic shape and uniform gradation, greatly increasing the market price and application range of the product.

• Higher Processing Capacity: The optimized cavity design and heavy-duty rotor allow for a larger material throughput per unit time, increasing output by approximately 20%-30% compared to traditional equipment.

• Lower Overall Operating Costs: Long wear part life, convenient maintenance, and high energy utilization efficiency significantly reduce the per-ton production cost in the long run.

• Flexible Adjustability: By adjusting the rotor speed and impact plate gap, the output particle size can be easily controlled to meet various production needs, enabling multi-purpose use of a single machine.

• Stable and Reliable Operation: The robust structural design and precise dynamic balancing test ensure long-term continuous and stable operation of the equipment under heavy-duty working conditions.

PF impact crusher crushing site

Application Case: Witnessing the Effectiveness of the Technology Solution

We provided a European-style impact crusher technology solution to a large granite quarry in East China. The customer's original production line had poor particle shape and weak product competitiveness. After adopting our solution and using our company's European-style high-performance impact crusher as the core of the secondary crushing process:

• Finished Product Particle Size: The needle-like and flaky content in the 25-40mm aggregate was successfully reduced from 15% to below 8%.

• Production Efficiency: Under the same feeding conditions, the hourly output increased by approximately 25%.

• Maintenance Costs: The service life of the hammerheads was extended by 40%, and the annual maintenance time was reduced by approximately 60 hours.

This case fully demonstrates the powerful capabilities of this technology solution in improving product added value and economic benefits.

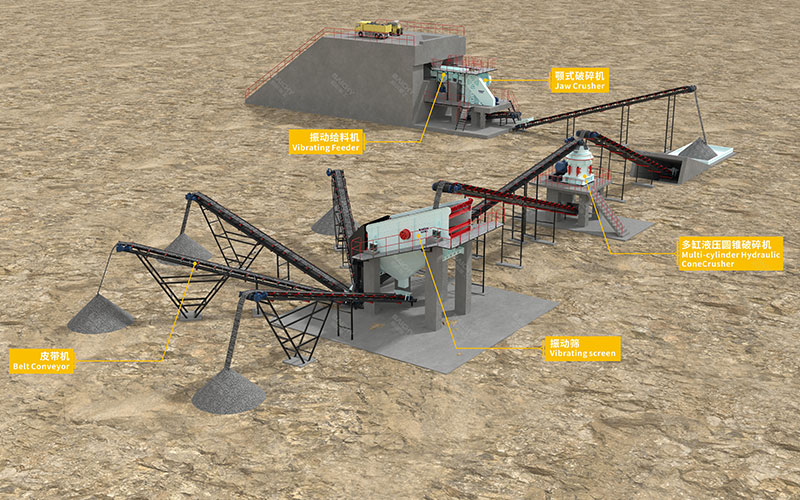

Related Equipment Recommendations: Building an Efficient Production Line

A complete European-style impact crusher technology solution requires the coordination of upstream and downstream equipment. We recommend the following equipment to build an optimal production line:

• Upstream: Pair with our company's deep-cavity jaw crusher for primary crushing, providing stable and uniform feeding to the impact crusher.

• Downstream: Connect to a circular vibrating screen to form a closed-loop system, or connect to a vertical shaft impact crusher (sand making machine) for sand production and shaping, achieving simultaneous production of sand and aggregate for maximum efficiency.

Impact crushing production line

FAQ

Q1: What are the main differences between European-style impact crushers and ordinary impact crushers?

A1: The main differences lie in the design philosophy and manufacturing standards. European-style crushers focus more on heavy-duty, high efficiency, and high-quality finished products, reflected in the heavy-duty rotor, hydraulic system, precision cavity design, and higher-grade wear-resistant materials, while ordinary impact crushers may focus more on basic functionality.

Q2: Is this solution suitable for processing very hard rocks (such as granite and basalt)?

A2: Absolutely. This is precisely where the European-style impact crusher technology solution excels. Its heavy-duty rotor and high-strength blow bars are specifically designed for hard rock crushing, but it is important to properly configure the production line and control the upstream feed size.

Q3: Is the replacement of wear parts complicated? What are the consumable costs?

A3: Thanks to the hydraulic opening design, replacing blow bars and opening the machine frame is very convenient. Although the cost of a single wear part may be slightly higher, its exceptionally long service life and the resulting high output and low downtime make the overall cost per ton significantly lower than ordinary equipment, offering better value for money.

Q4: Can we get on-site testing or solution design support?

A4: Absolutely. We provide free experimental analysis and production line process design based on customer material samples, and can arrange visits to successful operating case sites so you can witness the results firsthand.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.