In the fields of mining, aggregate production, and large-scale engineering construction, stable, efficient, and reliable crushing and screening production lines are crucial for enterprises to ensure supply, control costs, and win market competition. For enterprises pursuing large-scale and continuous operations, a fixed crushing and screening system with precise capacity design and stable operation is the core engine of production. Today, we take the 100-ton/hour capacity fixed crushing and screening equipment, which has received much attention in the industry, as an example to deeply analyze its core advantages, configuration options, and investment value, providing professional reference for your decision-making.

Why Choose a 100-ton/hour Fixed Production Line?

A fixed crushing and screening station, as the name suggests, has all main equipment permanently fixed on a solid concrete foundation or steel structure platform. Compared to mobile production lines, its biggest advantages are extremely stable operation, strong capacity guarantee, relatively lower energy consumption, and a high degree of automation, making it very suitable for use in large quarries, cement plants, or large-scale engineering projects with stable raw material sources and long production cycles (usually several years or more).

A capacity of 100 tons/hour is precisely the golden ratio for medium to large-scale production lines. It meets the continuous demand for sand and gravel aggregates in most regional markets while achieving an excellent balance between equipment investment, floor space, and energy consumption. This configuration can handle common materials such as limestone, granite, and river pebbles, and by adjusting the crushing chamber shape and screen specifications, it can also adapt to perse product particle size requirements.

Core Equipment Configuration Scheme Analysis

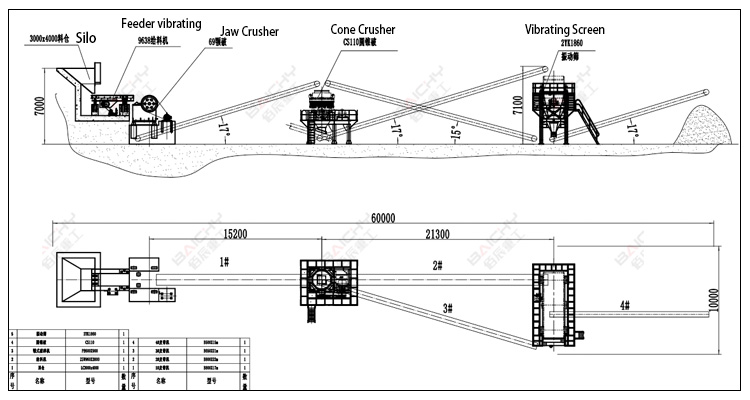

A high-efficiency 100-ton/hour stationary production line is not simply a combination of inpidual pieces of equipment, but a scientific system integration based on crushing and screening principles. Typical "two-stage closed-circuit" or "three-stage closed-circuit" processes are the mainstream choices. Below is an overview of a classic configuration scheme for medium-hardness materials (such as limestone):

| Section Name | Recommended Equipment Type | Model Reference Example | Main Functions and Features |

| Coarse Crushing Section | Jaw Crusher | PE600×900 | Responsible for the first stage of material crushing, with strong impact resistance and a large feed opening; it is the "throat" of the production line, determining the overall processing capacity limit. |

| Medium and Fine Crushing Section | Impact Crusher or Cone Crusher | PF-1214 / PY-1750 | Responsible for secondary crushing. Impact crushers are more suitable for applications with medium hardness and high product particle shape requirements; cone crushers are more wear-resistant, suitable for high-hardness materials, and have lower operating costs. |

| Screening Section | Circular Vibrating Screen | 3YK-1860 | Classifies crushed materials. Qualified materials enter the finished product stockpile, while substandard materials are returned to the crusher for further crushing (closed-loop circulation), ensuring a high product particle size qualification rate. |

| Feeding and Conveying | Vibrating Feeder, Belt Conveyor | GZD-960×3800, B650/800 |

Ensures uniform and continuous feeding, serving as the "lifeblood" of the production line's smooth operation. Its stability and sealing directly affect the on-site environment and efficiency. |

Ensures uniform and continuous feeding, serving as the "lifeblood" of the production line's smooth operation. Its stability and sealing directly affect the on-site environment and efficiency.

Note: The above are general reference configurations. Actual selection requires strict scientific calculation and design based on parameters such as material hardness, abrasiveness, inlet and outlet particle size, moisture content, and final product ratio.

Investment Return and Operational Advantages Analysis

From a marketing and investment perspective, this 100-ton/hour fixed production line brings long-term value to the company:

1. Stable and High Output, Guaranteed Profits: The fixed design avoids production stoppages caused by relocation and leveling of mobile stations. Equipment utilization can reach over 90%, and the annual effective production time far exceeds that of mobile production lines, ensuring annual output targets and contract fulfillment.

2. Lower Overall Costs: Although the initial infrastructure investment is higher, the unit price, service life, energy consumption per ton, and maintenance costs are generally superior to mobile stations with the same capacity. Its cost per ton is significantly advantageous over a lifespan of 5-10 years.

3. Intelligent Control, Convenient Management: Fixed stations are easier to integrate with advanced centralized control systems (PLCs), enabling one-button start/stop, remote monitoring, fault alarms, and automatic output data statistics. This significantly reduces reliance on operators and improves the level of management precision.

4. Environmental Protection and Image Enhancement: Systematic planning of dust collection (pulse bag filter), noise isolation, and wastewater recycling systems creates a green and environmentally friendly mine, complying with national environmental policies, enhancing the company's social image, and facilitating the acquisition of long-term mining permits.

Successful Application Scenarios

This scale production line is ideal for the following scenarios:

• Large commercial quarries: Continuously supplying various specifications of aggregates to commercial concrete plants, asphalt plants, precast component plants, and large-scale infrastructure projects.

• Cement companies' own mines: Providing high-quality limestone raw materials for cement production, while simultaneously producing commercial aggregates to increase profit margins.

• Long-term large-scale engineering projects: Dedicated sand and gravel processing bases established along water conservancy projects, highways, railways, etc.

• Solid waste resource utilization projects: Processing construction waste, tailings, etc., to produce recycled aggregates.

Choosing a 100-ton/hour fixed crushing and screening system is essentially choosing a robust and sustainable production model. It's not just about procuring hardware; it's the beginning of a partnership with an equipment supplier who possesses deep industry knowledge, comprehensive service capabilities, and a long-term cooperative relationship. As a company deeply rooted in the mining equipment field, we not only provide durable standalone machines, but also offer full lifecycle solutions from site surveys, process design, equipment selection, installation and commissioning to operation training, maximizing your return on investment and ensuring a solid foundation in market competition.