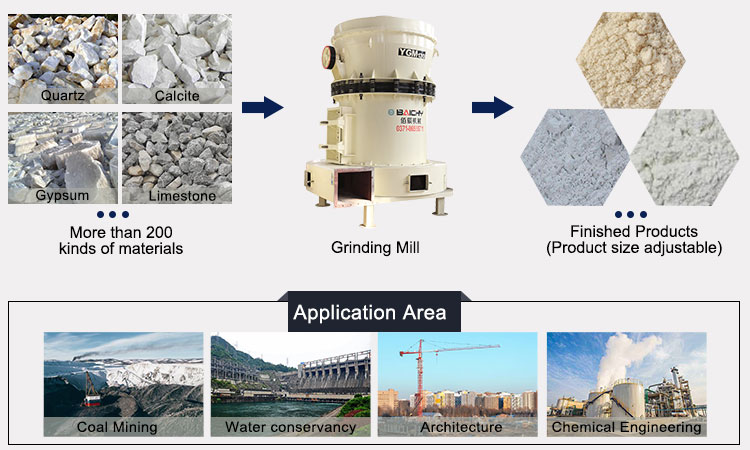

Raymond mill is usually used for grinding mineral products in the fields of metallurgy, building materials, chemical industry, mining, etc. It is often used for grinding coal powder, limestone grinding, barite grinding, dolomite grinding, and feldspar grinding, etc., sells well in Uzbekistan, Indonesia, India, Bangladesh, Ethiopia, Nigeria, and other countries.

Baichy will recommend different models according to different product particle sizes and products, such as the YGM130 grinder mill.

| Model | Roller number(pc) | Roller size | Max.feeder size(mm) | Output size(mm) | Capcity(t/h) | power(kw) | Overall dimension |

| YGM130 | 5 | 410x23030 | 30 | 0.613-0.033 | 0.613-0.033 | 90 | 7900x8000x9700 |

The number of grinding rollers of the YGM130 high-pressure pulverizer is 5, the diameter of the grinding roller is 410mm, the height of the grinding roller is 210mm, the diameter of the grinding ring is 1280mm, the height of the grinding ring is 210mm, the maximum feeding particle size is less than 30mm, the production capacity: 9t/h The finished product particle size is 0.95mm- 0.033mm, the host power is 75kw, the overall dimensions (length 7.85m, width 8m, height 9.7m).

The Grinding mill is usually equipped with a corresponding jaw crusher, impact crusher, cone crusher, vibrating feeder, and other equipment for rough ore crushing operations.

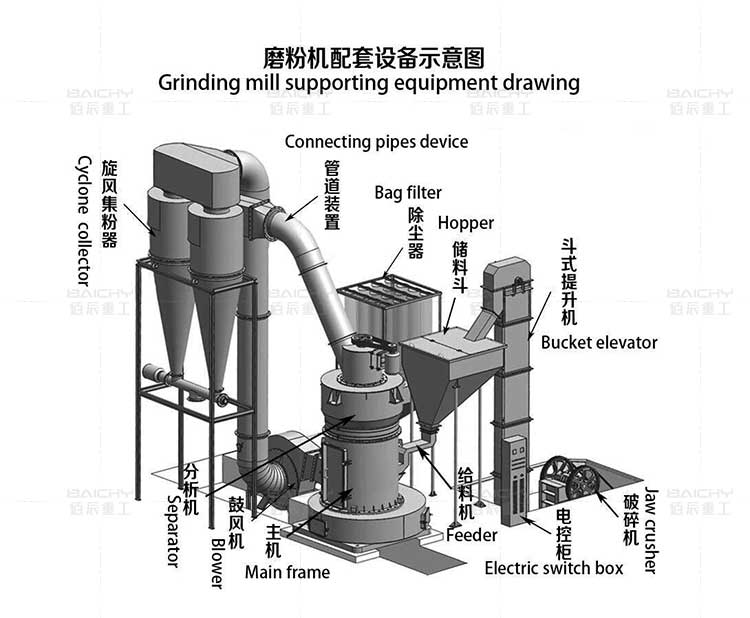

The high-pressure grinding roller mill is mainly composed of the main engine, a fineness analyzer, a blower, a finished cyclone powder accumulator, a bag filter, and a connecting air duct. The machine can produce 30-80 mesh coarse powder by adding a special device. The current main models are: YGM65, YGM75, YGM85, YGM95, YGM130

YGM High-pressure Grinding Mill Advantage

The high-pressure grinder mill is optimized and improved on the basis of the Raymond mill. Compared with the ball mill, the equipment has higher efficiency, lower power consumption, smaller floor space, and less one-time investment. The grinding roller is tightly pressed on the grinding ring under the action of centrifugal force, so when the grinding roller and the grinding ring are worn to a certain thickness, the output and fineness of the finished product will not be affected. The grinding roller and grinding ring have a long replacement cycle, which eliminates the shortcoming of the short replacement cycle of the wearing parts of the centrifugal pulverizer. The airflow of this machine is circulated in the fan-grinding shell-cyclone separator-fan, so it has less dust than the high-speed centrifugal pulverizer, and the operation workshop is clean.

The working principle of raymond mill

When the Raymond mill is working, the bulk raw materials are crushed to the required feeding particle size, and the materials are transported to the storage bin by the bucket elevator, and then evenly sent to the grinding chamber of the main machine by the electromagnetic vibrating feeder. The material in the grinding chamber is shoveled by the shovel and enters between the grinding roller and the grinding ring to be ground. For the sorting of the rotating analysis impeller, the large particle material falls back to the grinding chamber, regrinds, and the qualified fine powder enters the finished product cyclone powder collector with the airflow, and after being separated from the air, it is discharged from the discharge port as the finished product. During the working process of the main engine, the blade system plays a very important role. It is located at the lower end of the grinding roller. During the co-rotation of the shovel blade and the grinding roller, the material is shoveled and thrown into between the grinding roller rings to form a padding layer. Grinding to achieve the purpose of milling.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.