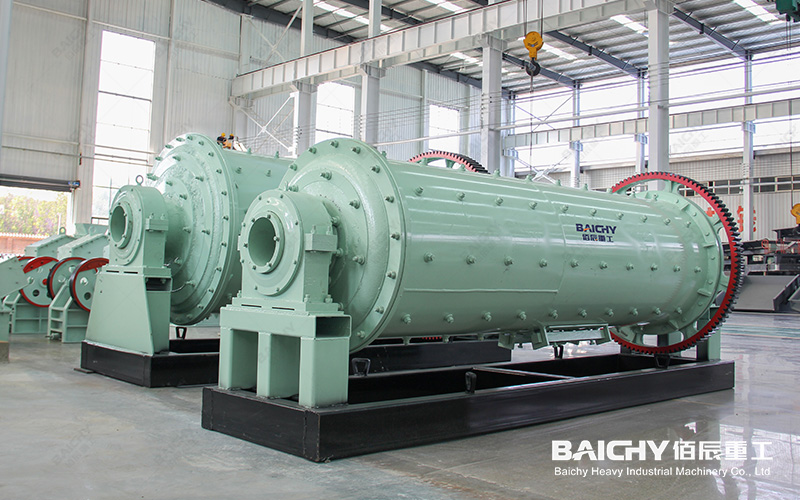

As the world's largest nickel producer and exporter, Indonesia's nickel ore mining and processing industry is developing at an unprecedented pace. In this industrial chain, the ore grinding stage is crucial, directly impacting the recovery rate of subsequent beneficiation and the quality of the final product. The 2400x4500 ball mill, with its excellent processing capacity and stable performance, has become the "heart" of many Indonesian nickel ore production lines.

Why is the 2400x4500 ball mill an ideal choice for Indonesian nickel ore production?

1. Superior Processing Capacity: This model of ball mill has a cylinder diameter of 2.4 meters and a length of 4.5 meters, classifying it as a medium-to-large-sized grinding device, ideally suited for processing raw ore from medium-to-large-scale nickel ore projects in Indonesia. Its single-unit processing capacity is considerable, effectively meeting the needs of large-scale production.

2. Strong Grinding Adaptability: Nickel ore is typically hard and may contain a certain amount of moisture. The 2400x4500 ball mill boasts a robust structure and a powerful transmission system, easily handling nickel ores of various properties to ensure uniform grinding fineness and create excellent conditions for subsequent processes such as flotation.

3. Stable Operation and Easy Maintenance: In Indonesia's relatively hot and humid environment, equipment reliability is crucial for continuous production. This ball mill utilizes mature design and manufacturing processes, with key components such as bearings and gears undergoing reinforcement treatment, resulting in a low failure rate and long maintenance cycles, minimizing downtime.

4. Balance of Energy Consumption and Efficiency: Through optimized design, the modern 2400x4500 ball mill prioritizes energy conservation and consumption reduction while ensuring grinding efficiency. The use of high-efficiency motors and transmission systems helps mining companies effectively control operating costs and improve overall economic benefits.

Special Considerations for Indonesian Application

When deploying the 2400x4500 ball mill in Indonesia, localized support must also be considered. Choosing an equipment supplier that can provide timely spare parts supply, localized technical guidance, and after-sales service is crucial to ensuring the production line operates efficiently 24/7.

In conclusion, the 2400x4500 ball mill has proven its value in the highly competitive Indonesian nickel ore market with its powerful processing capacity, excellent stability, and good economics. Investing in a high-performance ball mill injects powerful core power into the entire production line. Choosing the right equipment partner will be a crucial step towards success in the Indonesian nickel ore industry.