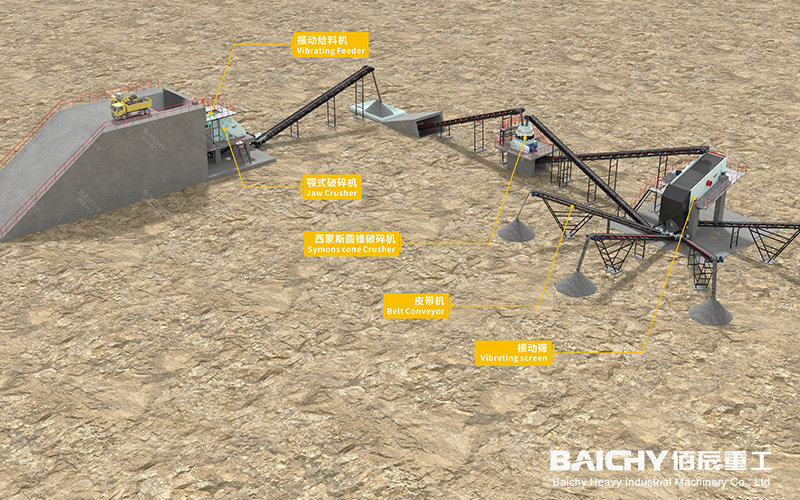

In today's booming market for sand and gravel aggregates, a scientifically designed and stably operating crushing production line is key to cost reduction and efficiency improvement for enterprises. A capacity of 200 tons per hour is a classic and highly efficient configuration, widely used in small and medium-sized stone quarries, commercial concrete plant support facilities, and various engineering construction projects. Today, we will delve into a 200-ton-per-hour crushing production line to see how it produces high-quality aggregates of various specifications through a perfect combination of "coarse crushing + medium and fine crushing + high-efficiency screening."

I. The Three Musketeers of the Production Line's Core Equipment

The stability and efficiency of this production line are inseparable from its core crushing and screening equipment. Each component performs its specific function, and they are interconnected.

1. Jaw Crusher: The Solid "Pioneer"

◦ Role: Primary Crushing (Coarse Crushing)

◦ Core Function: As the first stage in the entire production line, the jaw crusher, with its powerful crushing force and robust structure, is responsible for the initial "breaking down" of large pieces of raw ore (typically with a particle size of 500-600mm or even larger), crushing them into smaller stones with a particle size of approximately 150-250mm. Its stability and output particle size directly affect the production efficiency of subsequent equipment.

2. Cone Crusher (Cone Breaker): The Precise "Shaper"

◦ Role Positioning: Secondary crushing (medium and fine crushing).

◦ Core Function: Receives raw materials from the jaw crusher for further crushing and shaping. The cone crusher uses the principle of layered crushing, producing finished materials with excellent particle shape and low needle-like and flaky content, making it particularly suitable for producing high-standard concrete aggregates. It is wear-resistant and durable, making it an ideal choice for processing ores of medium hardness and above (such as granite and basalt).

3. 4-Layer Vibrating Screen: The Precise "Sorter"

◦ Role Positioning: Aggregate grading and screening.

◦ Core Function: This is the key equipment for ensuring the final product specifications. The 4-layer screen design allows for the precise separation of materials into up to 5 different sizes in a single pass.

Depending on the screen specifications you provide (S1, 3/8”, 3/4”, G1+1”), the screening process is typically as follows:

▪ Top Layer (G1+1” screen): Oversize aggregate larger than 1 inch (approximately 25.4 mm) is typically returned to the cone crusher for further crushing (forming a closed-loop cycle) to ensure maximum resource utilization.

▪ Second Layer (3/4” screen): Screens out aggregate between 3/4 inch (approximately 19 mm) and 1 inch, which is one of the commonly used and important sizes.

▪ Third Layer (3/8” screen): Screens out aggregate between 3/8 inch (approximately 9.5 mm) and 3/4 inch.

▪ Bottom Layer (S1 screen): Undersize material smaller than 3/8 inch, typically manufactured sand or stone powder.

II. Complete Production Line Equipment List

A complete production line includes far more than just the three main machines; it also includes crucial conveying and feeding systems:

• Feeding Equipment: Vibrating feeder, responsible for evenly and continuously feeding the stone from the raw material hopper into the jaw crusher, preventing the equipment from idling or overloading, acting as the "metronome" for efficient production.

• Crushing Equipment: Jaw crusher (1 unit), cone crusher (1 unit).

• Screening Equipment: 4-layer vibrating screen (1 or more units in parallel).

• Conveying Equipment:

◦ Belt Conveyors (multiple): Connecting all the equipment, forming the "arteries" for material flow. This includes conveyors from the feeder to the jaw crusher, from the jaw crusher to the cone crusher, from the cone crusher to the vibrating screen, and from each discharge port of the vibrating screen to the finished product stockpile.

◦ Waste Conveyor: Used to remove dirt, impurities, and other waste materials mixed in with the raw materials, improving the purity of the final aggregate and ensuring product quality.

• Auxiliary Systems: Electrical control system (the brain of the production line), dust removal system (ensuring environmental protection), etc.

III. Detailed Production Process Flow (Closed-Loop Cycle)

The material's journey in this production line is clear and efficient:

1. Feeding and Primary Screening: Raw ore is conveyed to the jaw crusher by a vibrating feeder. The feeder's built-in grates can pre-screen out some soil and fine materials.

2. Primary Crushing: Large stones are crushed into medium-sized particles in the jaw crusher.

3. Secondary Crushing and Screening: The material crushed by the jaw crusher is conveyed by a belt conveyor to a cone crusher for fine crushing. The crushed material is then lifted to a 4-layer vibrating screen.

4. Aggregate Grading: In the vibrating screen, the material is precisely screened into 4-5 types of finished products:

◦ Qualified Finished Products: 3/4″ aggregate, 3/8″ aggregate, and S1 sand are directly conveyed to different finished product stockpiles through their respective discharge ports by belt conveyors.

◦ Return Material: Oversize material larger than 1 inch (non-compliant large material) is returned to the cone crusher via a return conveyor belt for further crushing, forming a closed-loop cycle until it is crushed to the required particle size.

5. Finished Product Output: Ultimately, the production line simultaneously produces high-quality crushed stone and manufactured sand of various specifications.

IV. Core Advantages of this Configuration

• High and Stable Output: A configuration with an hourly output of 200 tons can meet the aggregate requirements of most projects, ensuring stable operation.

• Superior Product Quality: The combination of a jaw crusher and a cone crusher, especially the shaping function of the cone crusher, ensures that the aggregate has a cubic shape, reasonable gradation, and higher value.

• Energy Saving and Environmental Protection: The closed-loop design reduces waste; combined with dust removal equipment, it meets environmental protection requirements.