Recommended manufacturers of 15 t/h river sand drying system

In industries such as construction, building materials, and precast concrete, the moisture content of river sand is a key indicator determining its quality and applicability. Wet river sand is prone to adhesion and clumping, severely impacting transportation, screening, and batching accuracy, and further reducing the strength of the final product. Therefore, an efficient and stable drying system is an indispensable link in the high-value utilization of river sand resources.

A processing capacity of 15 tons/hour is a common requirement for medium to large-scale production lines. It balances investment costs and economies of scale, placing clear demands on the system's reliability, thermal efficiency, and automation level. As a manufacturer, we understand that precise equipment selection is the foundation of project success.

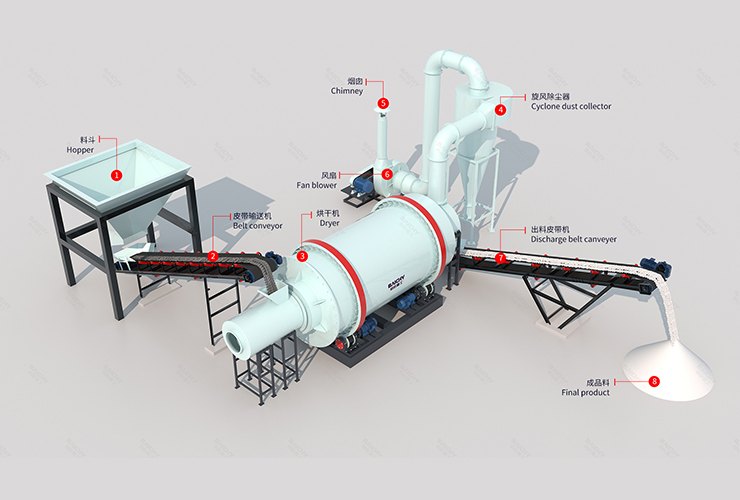

Core Components of a 15 t/h River Sand Drying System

A complete river sand drying production line is not a single piece of equipment, but a collaborative system. The core equipment is our three-pass rotary dryer, specifically designed for sandy materials, but the efficient operation of the entire system depends on the precise coordination of other components.

1. Core Drying Equipment: Three-Pass Rotary Dryer

This model adopts a "sleeve" structure, with three concentric cylinders inside. The wet sand is dried in the innermost layer in a co-current flow, in the middle layer in a counter-current flow, and then again in the outermost layer in a co-current flow for drying and cooling. This design ensures more thorough heat exchange, extremely low heat loss, and energy savings of up to 50% compared to single-drum dryers. It also requires less floor space and produces uniform and stable quality finished sand.

2. Supporting System Equipment

• Hot Air System: Includes coal/gas/oil-fired hot air furnaces and high-efficiency blowers, providing a stable and clean heat source.

• Feeding and Conveying System: Employs a sealed belt conveyor or screw feeder for uniform and continuous feeding, preventing dust generation.

• Dust Removal System: A pulse jet bag filter is essential. It effectively captures fine dust generated during the drying process, ensuring emissions meet environmental standards and allowing for product recovery, thus improving efficiency.

• Discharge and Screening System: The dried river sand is conveyed to a vibrating screen for grading, followed by cooling and packaging.

• Intelligent Control System: PLC centralized control, real-time monitoring of temperature, speed, and airflow, enabling one-button start/stop and fault alarms, ensuring stable system operation.

Dryer Flowchart

Core Advantages of Choosing Our System

With 20 years of experience in mineral processing equipment manufacturing, our river sand drying system boasts unparalleled advantages:

1. Excellent Energy Efficiency Ratio: Unique internal lifting plates and a three-layer structure maximize material residence time and heat exchange area, ensuring efficient river sand drying and significantly reducing fuel costs.

2. Robust and Durable, Stable Operation: The main cylinder is constructed of wear-resistant steel plates, with special treatment of key components, allowing for 24/7 continuous operation, low failure rate, and long service life.

3. Environmentally Compliant, Clean Production: The system operates under full negative pressure, combined with efficient dust removal, resulting in dust emission concentrations far below national environmental protection requirements, creating a friendly working environment.

4. One-Stop Turnkey Project: We provide comprehensive services from process design, equipment manufacturing, installation guidance to commissioning and training, ensuring rapid system commissioning and achieving designed output and quality.

Success Story Sharing

We built a 15-ton/hour river sand drying production line for a large building materials group in Central China. The client previously used an old-fashioned single-drum dryer, which was energy-intensive, had insufficient output, and faced significant environmental pressure. We customized a completely new system centered around a three-pass rotary dryer.

After the system was put into operation, the output stabilized at over 15.5 t/h, the moisture content of the discharged sand was consistently controlled below 0.5%, fuel consumption was reduced by approximately 40%, and gas emissions fully met standards after dust removal. The client recovered the equipment investment cost within 18 months through energy savings.

Equipment Recommendation List (Standard Configuration for a 15 t/h River Sand Drying System)

| Item No. | Equipment Name | Model/Specification | Main Function | Remarks |

| 1 | Three-pass River Sand Dryer | Φ2.2×12m | Core Drying Equipment | Main Motor Power 18.5kW |

| 2 | Biomass Hot Air Furnace | Calorific Value 4,500 Kcal | Provides Heat Source | Compatible with Gas and Oil Fuel |

| 3 | Pulse Bag Filter | 288 Bags | Flue Gas Purification, Dust Recovery | Filtration Area ≥240㎡ |

| 4 | Sealed Belt Conveyor | B650x15m | Feeding and Finished Product Conveying | Multi-stage Configuration |

| 5 | Disc Feeder | Variable Frequency Control | Uniform Quantitative Feeding | Key Stable Production Component |

| 6 | Exhaust Fan and Blower | Matching Model | System Ventilation and Heating | Customized Airflow and Pressure |

| 7 | PLC Control Cabinet | Centralized Control | Automated Operation and Monitoring | Includes Touchscreen |

Frequently Asked Questions (FAQ)

Q1: What is the approximate total installed power of the system for processing 15 tons of wet river sand? What is the daily energy cost?

A: The total power of the entire system (including the main unit, blower, conveyor, etc.) is approximately 80-100kW. Energy costs mainly depend on the heat source. If biomass pellets are used, based on a capacity of 15t/h and 20 hours of operation per day, the daily fuel cost is approximately the local biomass pellet price multiplied by the consumption of about 6-7 tons. Our efficient design can maximize your savings in this area.

Q2: How long does it take from installation to commissioning?

A: For a standard 15 t/h system, assuming your infrastructure is ready, our engineering team can complete the installation, commissioning, and operator training within 25-35 days, helping you to quickly start production.

Q3: What is the stable moisture content of the dried river sand?

A: This is one of the advantages of our system. Through precise control of temperature, air volume, and feed rate, the moisture content of the finished river sand can be stably controlled between 0.3% and 0.8%, fully meeting the requirements for high-quality construction sand.