In high-end industrial sectors such as glass, ceramics, casting, and electronics, extremely stringent requirements are placed on the purity and particle size of silica sand raw materials. A stable, refining silica sand production line is crucial for ensuring product quality and economic benefits.

This article will analyze in detail a refined silica sand production line solution that starts with relatively clean 0-0.5mm raw sand, employing a core process of "washing-magnetic separation-calcination," ultimately achieving a production capacity of 10 tons per hour and a stable silica purity of over 99%.

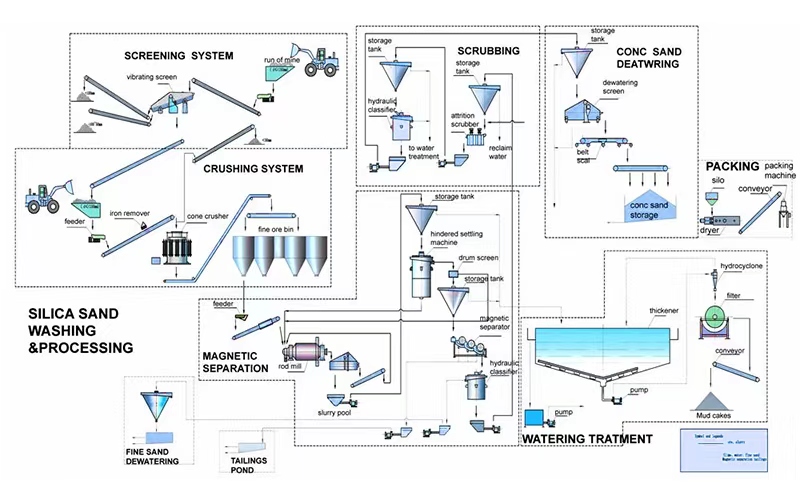

Core Process Analysis

1. Washing Process: Removing Surface Impurities and Dust

◦ Purpose: Although the raw sand is relatively clean, it may still contain washable impurities such as clay and dust. This process is fundamental for improving the whiteness and purity of the product.

◦ Process: A high-efficiency wheel-type sand washer or spiral sand washer is used. Through the friction and scouring action of water flow, sand particles are separated from impurities, and wastewater and fine particles are discharged through overflow.

2. Magnetic Separation Process: Deep Removal of Iron Impurities

◦ Purpose: Iron impurities are a key factor affecting the quality of silica sand, significantly reducing product whiteness and impacting its application in high-end fields. Magnetic separation is the core step in achieving 99% high purity.

◦ Process: A high-gradient, high-intensity magnetic separator is used to process the washed sand. The powerful magnetic field effectively removes iron-containing impurities, including weakly magnetic minerals (such as hematite and limonite), ensuring the chemical stability and high whiteness of the final product.

3. Calcination Process: Thorough Purification and Whitening

◦ Purpose: This is the crucial step in achieving ultra-high purity. Calcination effectively removes residual organic matter and water of crystallization from the sand particles and transforms small amounts of iron impurities into a form easily removed by subsequent acid washing or further magnetic separation, achieving deep whitening and purification.

◦ Process: The sand is heated in a high-temperature rotary kiln or pusher kiln under strictly controlled temperature and atmosphere conditions. This process significantly increases the silica content, ensuring a purity consistently exceeding 99%.

Production Line Advantages Summary

• High Output and Efficiency: The entire line is designed to have a capacity of 10 tons/hour, meeting the needs of large-scale industrial production.

• Superior Purity: Triple process guarantees a final product SiO₂ content ≥99%, meeting high-end application standards.

• Stable Particle Size: The gentle processing effectively maintains the original particle size distribution of the raw material (0-0.5mm), resulting in uniform product particles.

• High Return on Investment: The mature and reliable process route and stable equipment operation continuously generate high-value returns for customers.

Through the classic and efficient combination of "washing + magnetic separation + calcination," ordinary raw sand is successfully transformed into high-value-added refined silica sand products. This solution not only ensures a stable capacity of 10 tons/hour but also elevates the product purity to a high level of over 99%, making it an ideal choice for investors entering the high-end silica sand market.