What is the difference between river sand and crushed sand? A comprehensive analysis of the 5 core differences

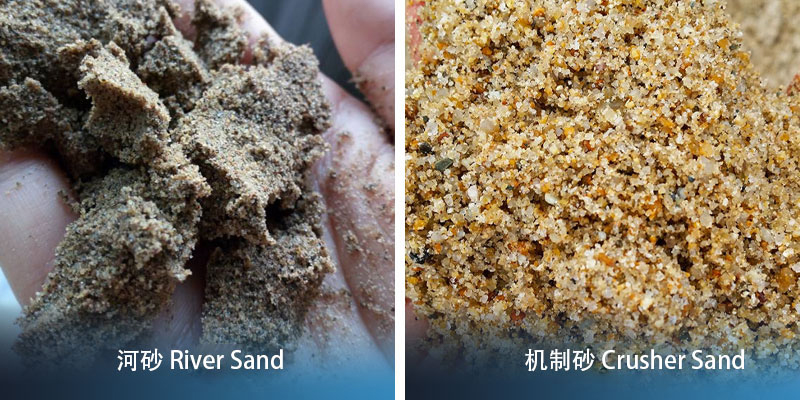

Sand is an indispensable material in construction, concrete, decoration and other projects. But what is the difference between the common river sand (natural sand) and crushed sand (mechanical sand) on the market? Which one is more suitable for your project? This article will make an in-depth comparison from the five dimensions of source, particle shape, mud content, price, and environmental protection to help you make the best choice!

1. Different sources: natural vs. artificial

River sand (natural sand)

• Formed by natural scouring of rivers, after long-term water transportation, the particles are rounded.

• Main ingredients: minerals such as quartz and feldspar, containing a small amount of soil and organic matter.

Crushed sand (mechanical sand)

• Processed by mechanical crushing (such as jaw crusher, impact sand making machine), the raw materials are mostly granite, limestone, basalt, etc.

• The particles are angular and the fineness modulus can be adjusted according to needs

Applicable scenarios:

• River sand: suitable for plastering, masonry, decoration and other scenarios that require high sand fluidity.

• Crushed sand:more suitable for projects that require high compressive strength such as high-strength concrete and roadbed filling.

2. Particle shape comparison: roundedvs.angular

| Characteristics | River sand | Crushed sand |

| Particle shape | Rounded,smooth | Angular,rough |

| Flowability | Flowability | Good,easytoconstruct |Poor,needstoadjusttheproportion |

| Adhesion | General | Stronger(becausetheangularedgesincreasetheaggregatebiteforce) |

Impact:River sandhasgoodfluidityandissuitableforpumpingconcrete;crushedsandhasmanyangularedges,whichmayincreasethestirringresistance,butcanimprovethestrengthofconcrete.

3. Differencesinmudcontent:naturalimpuritiesvs.controllablecleanliness

River sand:naturallyformed,maycontainsoil,shells,organicmatter,andneedstobecleaned(mudcontentisgenerally≤3%).

Crushed sand: artificially produced, the mud content can be controlled (usually ≤1%), but the stone powder content is high (the concrete mix ratio needs to be adjusted).

Standard reference:

National standard "GB/T 14684-2022" stipulates:

Class I sand (high standard): mud content ≤1.0%

Class II sand (for ordinary construction): mud content ≤3.0%

4. Price comparison: Which has lower cost?

| Sand type | Market price (reference) | Influencing factors |

| River sand | Higher (80-150 yuan/ton) | Mining is limited, transportation costs are high |

| Crushed sand | Lower (50-100 yuan/ton) |

Trends:

• River sand is in short supply due to environmental protection restrictions, and prices fluctuate greatly;

• Crushed sand can be produced on a large scale, and long-term costs are more stable.

5. Environmental protection: Which is more sustainable?

River sand:

Disadvantages: Excessive mining damages the riverbed ecology, and mining has been banned in many areas.

Advantages: Natural materials, no additional processing energy consumption.

Crushed sand:

Disadvantages: Production requires electricity and may produce dust and noise pollution.

Advantages: Mine waste (such as tailings sand) can be used, which is in line with the circular economy.

Summary: How to choose?

| Demand | Recommended sand type |

| High-strength concrete, roadbed | Crushed sand (mechanical sand) |

| Plastering, masonry, decoration | River sand (good fluidity) |

| Low cost, stable supply | Crushed sand |

| High environmental protection requirements | Crushed sand (in line with policy trends) |

Final recommendation:

• If the budget is sufficient and the project allows, river sand (good fluidity) is preferred;

• If cost, strength, and environmental protection are considered, crushed sand is a better choice!

Extended question

1. Can crushed sand completely replace river sand?

It is completely possible in high-strength concrete, but ordinary plastering may require adjustment of the mix ratio.

2. How to test the quality of sand?

Pay attention to the mud content, fineness modulus, and crushing value (refer to GB/T 14684-2022).

If you have sand and gravel procurement needs, please leave a message for consultation! WhatsApp: 0086 15093222637

Recommended machine-made sand equipment:impact sand making machine | hammer sand making machine | roller sand making machine | mobile sand making machine