In the field of artificial sand making, the VSI-1145 vertical shaft impact crusher has become a mainstay for many sand and gravel producers due to its stable and efficient performance. This article will provide an in-depth analysis of the technical parameters, working principle, and advantages of the VSI-1145 crusher, helping you to fully understand this equipment.

Sand Making Machine PDF, Download ↓↓↓

I. Overview of Core Parameters of the VSI-1145 Crusher

The VSI-1145 model typically indicates that its rotor diameter is approximately 1145 mm. The following is a table of typical basic parameters for this model; please refer to the data provided by the actual manufacturer when purchasing.

| Parameter Items | Parameter Values | Detailed Description |

| Detailed Description | VSI-1145 | Industry standard model, indicating equipment specifications |

| Maximum Feed Size | ≤ 50 mm | Upper limit of feed size to ensure efficient operation |

| Processing Capacity (Output) | 120 - 280 t/h | Output fluctuates depending on material hardness and finished product particle size requirements |

| Main Shaft Motor Power | 180 - 220 kW | Powerful motor, ensuring crushing force and production efficiency |

| Impeller Speed | 1500 - 2000 r/min | High speed is key to obtaining high-quality particle shape |

| Dimensions (L×W×H) | Approx. 4100 × 2300 × 2500 mm | Space required for equipment installation |

| Total Weight | Approx. 12 - 14 tons | Reflects the robustness and stability of the equipment's materials |

II. In-depth Interpretation of Key Parameters

1. Processing Capacity: Why a Range?

The 120-280 tons/hour shown in the table is a theoretical range. Actual output is affected by several factors:

• Material hardness: When crushing high-hardness materials such as granite and basalt, the output tends to be at the lower-middle limit, around 150-200 tons/hour; while when processing medium-hard materials such as limestone, the output can approach the upper limit.

• Finished product particle size: The finer the finished sand required, the lower the output; conversely, if the fineness requirement is not high, the output will be higher.

• Material moisture/dust content: Materials that are too wet or have too high a dust content are prone to sticking together, affecting the throughput and thus reducing output.

2. Feed particle size: An indispensable "hard requirement"

≤50mm is a parameter that must be strictly adhered to. If the discharge from the upstream crushing equipment (such as jaw crusher and cone crusher) is not effectively controlled, excessively large stones entering the sand making machine will drastically accelerate the wear of the impeller and flow channel plates, and may even lead to impeller imbalance and vibration shutdown, resulting in huge maintenance costs and time losses.

3. Motor Power: The "Heart" of High-Efficiency Production

A power configuration of 180-220kW provides ample power for the high-speed rotation of the impeller. This ensures that the material is accelerated to a sufficient linear velocity, achieving thorough "stone-on-stone" or "stone-on-iron" crushing, thereby obtaining high-quality manufactured sand with excellent particle shape and reasonable gradation.

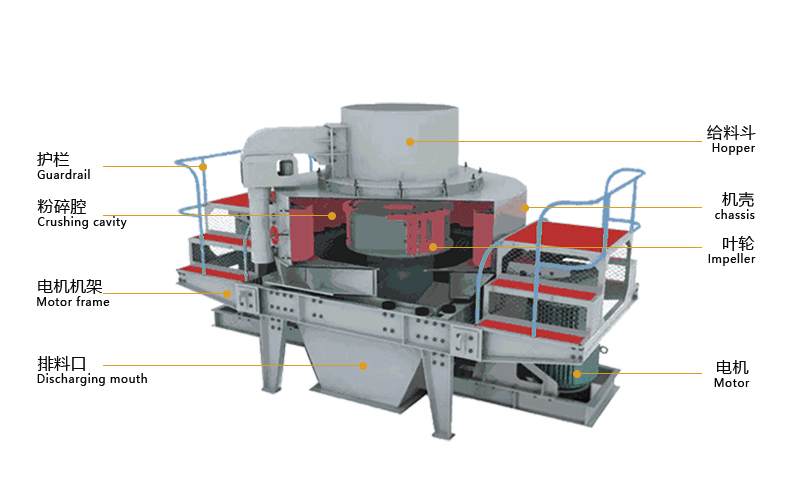

III. What is the Working Principle of the VSI-1145 Sand Making Machine?

The VSI-1145 sand making machine adopts a mature working principle combining "stone-on-stone" and "stone-on-iron" crushing.

• Center Feed: Material falls into the feed hopper and enters the high-speed rotating impeller through the center feed hole.

• Accelerated Projection: The material is rapidly accelerated inside the impeller and projected out of the impeller flow channel at a speed of 60-70 meters per second.

• Impact Crushing: The projected material violently impacts and rubs against the material lining (stone-on-stone) formed in the vortex crushing chamber or the wear-resistant blocks (stone-on-iron) on the peripheral guard plate, thereby achieving crushing and shaping.

This unique self-impact crushing principle produces cubic sand particles with very little needle-like or flaky content, making it an ideal choice for commercial concrete and high-standard construction projects.

IV. Equipment Advantages and Applicable Scenarios

Core Advantages:

• Excellent Particle Shape: The finished sand has a reasonable particle size distribution, strong compressive strength, and higher value.

• Multi-functional: It can be used for sand making and stone shaping, increasing the selling price of aggregates.

• Convenient Maintenance: The side guard plates can be reversed for use, and the wear parts have a long replacement cycle, effectively reducing operating costs.

• Environmentally Friendly and Energy-Saving: It can adopt a closed structure and be equipped with a dust removal system to meet environmental protection requirements.

Applicable Materials: River pebbles, granite, basalt, limestone, tailings, and recycled construction waste, etc.

V. Price and Selection Recommendations

The price of the VSI-1145 sand making machine varies greatly depending on factors such as brand, configuration, and market supply and demand. The price of one machine ranges from tens of thousands to hundreds of thousands of RMB. We recommend the following:

1. Define your needs: Determine the main materials to be crushed, target output, and finished product specifications.

2. Compare manufacturers: Choose reputable and well-known brands like Zhongyu Dingli, and consult multiple manufacturers to obtain detailed quotes.

3. Comprehensive consideration: Consider not only the unit price of the equipment, but also long-term operating costs such as the lifespan of wear parts, power consumption, and after-sales service quality.

The VSI-1145 sand making machine is a medium-sized sand making equipment with balanced performance and high market recognition. By understanding the meaning behind its parameters, you can make a more scientific equipment selection, laying a solid foundation for investing in and building an efficient and profitable sand and gravel production line.