Vertical Grinding Mill Customer Site

Overview: The Key Link Connecting Mines and Kilns

As a professional manufacturer of mobile crushing equipment for mines, we have a deep understanding of the complete process from mining to the final cement product. In cement production, the preparation of cement raw materials is a crucial step, and the vertical roller mill is the core equipment in this process. It efficiently grinds crushed raw materials such as limestone, clay, and iron powder into uniform fine powder, providing qualified raw materials for the subsequent calcination process, acting as a technological bridge connecting the front-end crushing and the back-end calcination.

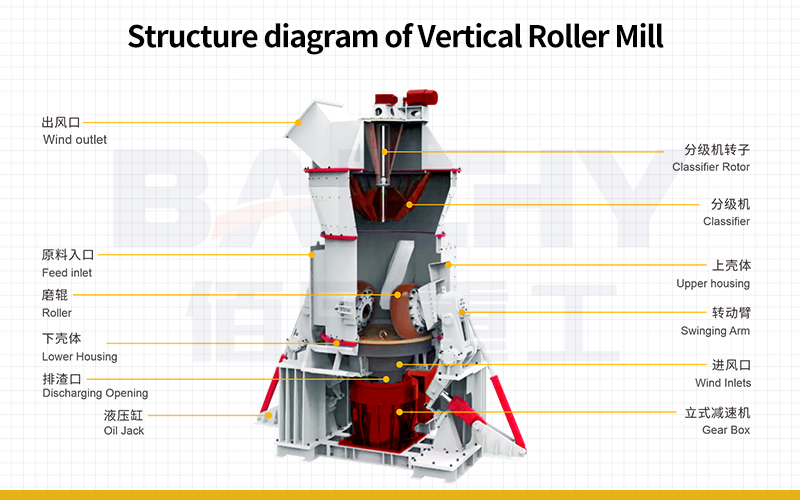

Technical Analysis: Working Principle of Vertical Roller Mills for Cement Raw Materials

The vertical roller mill achieves efficient processing of raw materials through its unique design. Materials enter the center of the grinding plate via the feeding system and move towards the edge under centrifugal force. A hydraulic system drives the grinding rollers to crush the material layer, achieving bed grinding. Simultaneously, hot air (up to 450°C) introduced from the bottom of the grinding plate thoroughly dries the material. Fine powder is carried by the airflow into the classifier for grading, and unqualified coarse powder is returned for further grinding, forming a closed-loop circulation system.

Significant Advantages of Vertical Roller Mills for Cement Raw Materials

Compared with traditional ball mill systems, vertical roller mills demonstrate revolutionary advantages in processing cement raw materials.

Excellent Energy Efficiency

Using the principle of bed grinding, energy is directly applied to the material, reducing electricity consumption by 30-50% compared to traditional ball mill systems. For a standard 5000 t/d production line, this can save millions of yuan in electricity costs annually in the raw material preparation stage alone, significantly reducing production costs.

Excellent Drying Capacity

It can handle raw materials with a moisture content of up to 15-20%, combining drying and grinding into one process. This feature allows it to directly process crushed materials from the front end without the need for separate drying equipment, making it particularly suitable for integrated production systems with mobile crushing plants at the mine site. H3: Stable and Uniform Product Fineness

By adjusting the classifier speed, the product fineness can be precisely controlled (typically 10-15% residue on an 80μm sieve, and <1.5% residue on a 200μm sieve), ensuring uniform chemical activity of the raw material, which is beneficial for the stable operation of the kiln system and the improvement of clinker quality.

Compact and Environmentally Friendly Process Flow

Integrating grinding, drying, and classification into one system, the system is simple and occupies a small footprint. Fully enclosed negative pressure operation ensures dust emission concentration can be controlled below 20mg/Nm³, meeting the strictest environmental standards.

| Key Words |

Dolomite Grinding Equipment |

| Product Model |

Vertical Roller Mill |

| Feed Size |

0-38mm |

| Capacity |

10-120t/h |

| Core Functions |

The crushing and grinding action of the rollers. |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Success Story: A Complete System from Mobile Crushing to Raw Material Preparation

We provided a complete raw material handling solution for a large cement project in the Middle East. The front end was configured with a mobile jaw crusher + cone crusher combination, completing two-stage crushing of limestone at the mine site, with the crushed product particle size controlled at 0-40mm. The material was then transported to the plant's pre-homogenization stockpile via a long-distance belt conveyor.

Core Link: The pre-homogenized raw material was fed into a large domestic vertical roller mill for cement raw materials. This equipment successfully processed mixed raw materials containing a certain amount of moisture, achieving a system output of 420 t/h, with a unit power consumption of only 13.5 kWh/t. The product fineness and moisture content fully met the design requirements. The stable operation of the vertical mill laid a solid foundation for the efficient operation of the subsequent rotary kiln.

Related Equipment Recommendations

Mobile Jaw Crushing Station: As the primary crushing equipment, it provides the first stage of crushed product for the vertical mill system, serving as the "first line of defense" to ensure the stable operation of the subsequent process.

Mobile Cone Crushing Station: Used for medium and fine crushing of raw materials, it can precisely crush materials such as limestone to the optimal feed particle size for the vertical mill (usually <50mm), optimizing the working efficiency of the vertical mill.

Heavy-duty Plate Feeder and Long-distance Belt Conveyor: Responsible for stable transportation from the mobile crushing station to the pre-homogenization stockpile or the vertical mill raw material silo, ensuring the continuous and reliable operation of the entire raw material supply system.

Raw Material Pre-homogenization Stockpile Equipment: Including stackers and reclaimers, ensuring that the raw materials entering the vertical mill have a uniform and stable composition, which is an important link in guaranteeing the quality of the raw materials.

Mobile Jaw Crusher Station

Mobile Cone Crusher Station

FAQ Frequently Asked Questions

Q1: What are the specific requirements for the feed particle size of the cement raw material vertical mill?

A1: The ideal feed particle size should be controlled below 30-50mm. Excessively large particle sizes will increase grinding roller pressure, leading to increased vibration and energy consumption; too much fine powder will affect the stability of the material bed. This is why high-efficiency mobile crushing equipment is needed at the front end, using two or three stages of crushing to provide the vertical mill with raw materials of uniform particle size and reasonable gradation.

Q2: How to handle high-moisture raw materials? Are there any limitations to the drying capacity of the vertical mill?

A2: The vertical mill has powerful drying capabilities and can usually handle raw materials with a moisture content of 6-8%. Through optimized system design, it can handle raw materials with a moisture content of up to 20%. The key is the capacity matching of the hot air system. For raw materials with particularly high moisture content, it may be necessary to increase the hot air furnace capacity or set up a pre-drying system. Our engineering team can provide customized solutions based on the specific characteristics of the raw materials.

Q3: Is the technology of Chinese-made raw material vertical mills mature and reliable? How is the supply of spare parts guaranteed?

A3: The technology of Chinese-made cement raw material vertical roller mills is fully mature and has reached internationally advanced levels. Currently, almost all newly built production lines of mainstream domestic cement companies use domestically produced vertical mills. Our cooperating manufacturers have a complete service network, providing 24-hour response technical support and original spare parts supply to ensure the long-term stable operation of the equipment.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!