Coal crushing

In coal crushing production lines, coarse crushing is the cornerstone of the entire process, and the selection of its equipment directly affects the efficiency of subsequent processes and the quality of the final product. This article will delve into why jaw crushers are the enduring and reliable choice for the coarse crushing stage of coal processing.

I. Challenges and Core Requirements of Coal Coarse Crushing

Coal, as a relatively soft mineral that may contain impurities such as gangue, faces several core challenges in its coarse crushing stage:

1. Large Piece Processing Capacity: The large particle size of raw coal requires equipment with a strong initial biting force.

2. High Impact Resistance and Abrasion Resistance: Hard gangue that may be mixed in the material poses a severe test to the vulnerable parts of the equipment.

3. High Processing Capacity and Stability: Coal production lines aim for continuous, stable, and efficient production, requiring reliable equipment operation.

4. Appropriate Discharge Particle Size: The discharge from coarse crushing needs to be uniform and moderate to prepare for subsequent medium and fine crushing processes, avoiding clogging or over-crushing.

Jaw Crusher - Coal Crushing Plant

II. The "Stabilizing Force" in the Coarse Crushing Stage

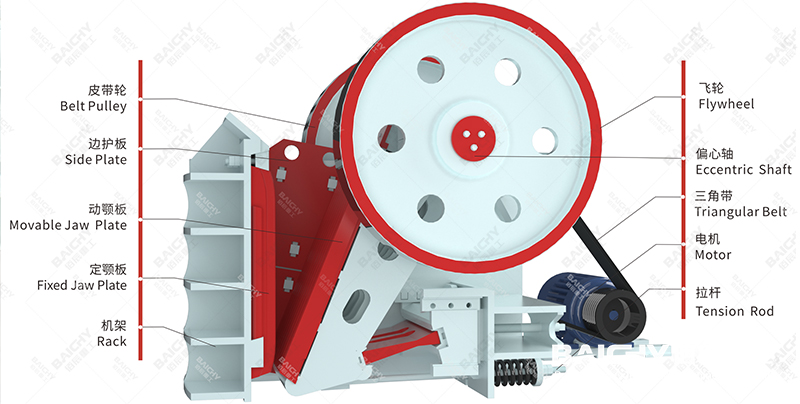

The jaw crusher, or jaw breaker for short, has long held a leading position in coarse crushing equipment due to its simple structure, reliable operation, convenient maintenance, and strong adaptability. Its working principle mimics the movement of an animal's jaws; the moving jaw plate periodically approaches and moves away from the fixed jaw plate, squeezing, splitting, and bending the material falling into the chamber, thus achieving crushing.

PE jaw crusher structural diagram

Why Does Coal Coarse Crushing Prefer Jaw Crusher? Four Core Advantages

1. Exceptional "First Crushing" Capacity and High Crushing Ratio

The jaw crusher has a large feed opening, easily accepting large pieces of raw coal. Its powerful compressive force is sufficient to crush large pieces of coal to a size suitable for subsequent processing in one go. The high crushing ratio effectively reduces the number of crushing stages and simplifies the process flow.

2. Robust Structure and Strong Impact Resistance

The main structure of the equipment is robust, with the moving jaw assembly made of heavy-duty cast steel and the eccentric shaft made of high-strength forged billets. It can withstand occasional impacts from gangue in coal, ensuring stable operation and a low failure rate.

3. Easy Maintenance and Controllable Operating Costs

The jaw crusher's structural design is intuitive, and easily replaceable wear parts (such as jaw plates). As a manufacturer with 20 years of experience, we provide high-manganese steel jaw plates with excellent wear resistance, significantly extending maintenance cycles and reducing long-term spare parts costs and downtime.

4. Wide Adaptability

Whether it's hard coal, lignite, or mixed gangue, the jaw crusher can effectively handle the raw materials. By adjusting the discharge port, the product particle size can be flexibly controlled to meet the next stage of feeding requirements for different customers.

Successful Case Study: Application of Jaw Crusher in Coal Crushing Plants

A large domestic coal washing and processing enterprise experienced frequent failures of its original coarse crushing equipment, affecting the entire production line. We recommended and configured a PE-900×1200 large-scale deep-cavity jaw crusher for them. After the modification:

• Processing capacity: Stably reaches 220-380 tons/hour, fully matching the designed capacity.

• Discharge particle size: Controlled below 150mm, with uniform particle size, creating perfect conditions for subsequent hammer crushing.

• Maintenance feedback: After one year of operation, the core components showed no abnormalities, and jaw plate wear was within the expected range. The customer highly praised its stability and low maintenance costs.

Equipment Recommendation and Process Matching Suggestions

We recommend using the classic process of "jaw crusher (coarse crushing) + impact crusher/hammer crusher (medium and fine crushing) + vibrating screen (classification)" in a complete coal crushing and screening production line. For those focusing on coarse crushing, we recommend the following model:

• PE series deep-cavity jaw crusher: A classic model, the king of cost-effectiveness, suitable for most standard coal coarse crushing scenarios.

• HD German-style high-power jaw crusher: Utilizing superior cavity design and manufacturing processes, it achieves higher output at the same power level and longer wear part life, making it suitable for large-scale projects with higher requirements for capacity and durability.

Frequently Asked Questions (FAQ)

Q1: What are the differences between jaw crushers and hammer crushers for primary coal crushing?

A1: Jaw crushers are more suitable as the first primary crusher, handling large pieces of raw coal, offering strong impact resistance and good controllability of output particle size. Hammer crushers are typically used for medium and fine crushing. Although they can produce a single-stage crush, the hammers wear very quickly when handling large pieces of raw coal containing impurities, making them uneconomical. Therefore, a combination of "jaw crusher for primary crushing + hammer crusher for fine crushing" is more efficient and economical.

Q2: Will jaw crushers easily clog when handling wet coal?

A2: High moisture content in sticky, wet coal does increase the risk of clogging. Our solutions are: First, when selecting equipment, choose a larger size and adjust the discharge port; second, optimize the jaw plate tooth design to facilitate material discharge; third, and most fundamentally, we recommend initial drying or moisture reduction of the material upstream, as this is a process issue that requires a systematic solution.

Q3: How to maximize the service life of the jaw crusher's jaw plates?

A3: There are three key points:

① Select jaw plates made of high-hardness material; we use custom-made alloy high-manganese steel;

② Regularly check and tighten bolts to prevent loosening and accelerated wear;

③ Ensure that material is fed evenly and continuously into the crushing chamber to avoid unilateral wear or iron damage; consider equipping with an iron separator and a feeder.

In the field of coal crushing, using a jaw crusher for coarse crushing is a proven, efficient, and reliable technology. Its superior coarse crushing capacity, robust and durable structure, and economical operating costs are the cornerstone of ensuring the stable operation of the entire production line.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!