Vertical Roller Mill

Overview: An Intelligent Hub Connecting Mining and Clinker Calcination

As a professional manufacturer of mobile mining crushing equipment, we have a deep understanding of the complete cement production chain, from mine to finished product. In the cement production line, the raw material vertical roller mill (SRM) is the core of the raw material preparation section. It efficiently grinds crushed raw materials such as limestone, clay, and iron-containing corrective materials into raw meal powder with uniform chemical composition and qualified fineness. This equipment is like the "precision stomach" of a cement plant; its performance directly determines the quality of the raw meal, energy consumption levels, and the stable operation of the entire system.

Technical Analysis: How Does the Cement Raw Material Vertical Roller Mill (SRM) Work?

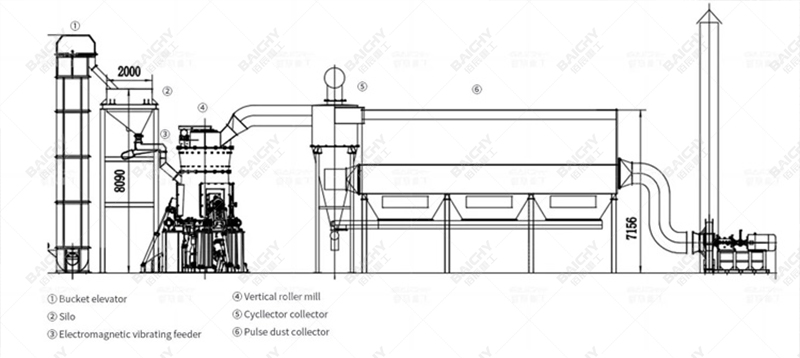

The cement raw material vertical roller mill is a grinding equipment specifically designed for processing cement raw materials. Its working principle is: the mixed raw materials, pre-processed and pre-homogenized by the front-end mobile crushing equipment, enter the center of the grinding disc through the feeding system. The grinding disc rotates under the drive of a reducer, and the material is thrown towards the edge of the grinding disc by centrifugal force. The hydraulic system applies enormous pressure to the grinding rollers, and the material is crushed and ground between the grinding rollers and the grinding disc using the principle of material bed grinding. At the same time, hot air (up to 450°C) introduced from the bottom of the grinding disc fully dries the material. Fine powder is carried into the classifier by the hot air for classification; the qualified raw meal powder is collected, and the coarse powder is returned to the grinding disc for further grinding.

Significant Advantages of the Raw Material Vertical Roller Mill (SRM)

Compared with traditional air-swept mills or ball mill systems, the raw material preparation system using a vertical roller mill has revolutionary advantages.

Unparalleled Energy Saving Effect

This is the core advantage of the SRM. Its unique material bed grinding method has extremely high energy utilization efficiency, and the system's power consumption is 30%-50% lower than that of traditional ball mill systems. A medium-sized SRM can save millions of kilowatt-hours of electricity per year, making it a key equipment for cement plants to reduce overall power consumption and achieve green production.

Excellent Drying and Grinding Capabilities

The SRM integrates grinding, drying, and classification, and can efficiently process mixed raw materials with a moisture content of up to 8%-20%. This powerful drying capability allows it to adapt to various humidity conditions, reducing the need for pre-drying of raw materials and making the layout of the upstream mine crushing process more flexible.

Uniform and Stable Raw Material Quality

Through precise control of the classifier speed and airflow, the fineness of the raw material can be stably controlled (typically 10%-15% residue on a 0.08mm sieve, and <1.5% residue on a 0.2mm sieve), and the chemical composition is highly uniform. This lays a solid foundation for stable calcination in the subsequent rotary kiln and the production of high-quality clinker.

Compact System and Excellent Environmental Performance

The equipment has a high degree of integration and a small footprint, reducing civil engineering investment. The entire system operates under negative pressure in a sealed environment, and with the help of a high-efficiency bag filter, the dust emission concentration can be easily controlled below 20mg/Nm³, far exceeding national environmental standards.

| Key Words |

Dolomite Grinding Equipment |

| Product Model |

Vertical Roller Mill |

| Feed Size |

0-38mm |

| Capacity |

10-120t/h |

| Core Functions |

The crushing and grinding action of the rollers. |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Success Story: A Model Project from Mobile Crushing to SRM Grinding

A turnkey EPC project we undertook in Southeast Asia perfectly demonstrates the seamless connection between mobile mine crushing and raw material vertical mill grinding. The front end of the project uses our designed "mobile jaw crusher + mobile cone crusher" semi-mobile crushing system to crush limestone to 0-50mm at the quarry and transport it to the plant via a long-distance belt conveyor.

Grinding Core: After pre-homogenization, the raw material is fed into a large domestic vertical roller mill. This SRM system has a production capacity of 420 t/h, and the unit power consumption for raw material grinding is only 12.5 kWh/t. It successfully handled the challenge of high raw material moisture content (average 12%) during the local rainy season, achieving a system operating rate of over 95%, creating significant economic benefits for the client.

Related Equipment and System Recommendations

Semi-mobile/Mobile Crushing Station: Provides stable and qualified raw materials for the SRM. It can be configured with a mobile jaw crusher for primary crushing and a mobile cone crusher for secondary medium and fine crushing to ensure optimal particle size for grinding.

Plate Feeder and Stacking/Reclaiming Equipment: Responsible for reliable transportation and homogenization of raw materials from the crushing station to the pre-homogenization stockpile, which is key to ensuring a stable "feed" for the SRM.

High-Efficiency Pulse Jet Baghouse Dust Collector: Paired with the SRM system, it ensures ultra-low dust emissions throughout the entire process, meeting the strictest environmental requirements.

Intelligent Control System: Including DCS and online analyzers, it enables real-time monitoring and automatic adjustment of raw material composition, ensuring optimal and stable quality of raw materials produced by the SRM.

Mobile Jaw Crusher

Mobile Cone Crusher

DMC Pulse Dust Collector

FAQ Frequently Asked Questions

Q1: What are the specific requirements for the raw material particle size provided by the front-end crushing system for the SRM?

A1: The ideal feed particle size should be controlled within 0-50mm, and the particle size distribution should be "small at both ends and large in the middle," avoiding excessive large particles (>50mm) and fine powders. This needs to be achieved through the rational configuration of front-end mobile crushing equipment (such as jaw crusher for coarse crushing + cone crusher for medium and fine crushing). A suitable particle size forms a stable material bed, which is the basis for efficient, low-vibration, and energy-saving operation of the SRM.

Q2: How does the SRM system cope with significant fluctuations in raw material moisture content?

A2: Modern SRM systems are designed to accommodate fluctuations in raw material moisture content. The main countermeasures include: 1) Adjusting the fuel supply of the hot air furnace or introducing higher temperature kiln exhaust gas to increase the temperature and volume of the hot air entering the mill; 2) Setting relevant parameters in the DCS system for automatic adjustment. For special cases with particularly high moisture content (>20%), simple pre-drying facilities can be considered at the front end, or preliminary drying can be carried out at the mine site in conjunction with the mobile crushing system.

Q3: As a crushing equipment manufacturer, why should we understand SRM? What value does this bring to our customers?

A3: Cement production is a systems engineering process; crushing is the starting point, and grinding is the key. A deep understanding of the technical characteristics and raw material requirements of the downstream SRM helps us design more suitable and economical overall front-end crushing solutions for our customers. For example, we can precisely control the particle size and gradation of the crushed products, optimizing the efficiency of the SRM from the source, helping customers achieve the lowest overall cost and energy consumption from the mine to raw material grinding, thus providing value-added services far beyond the sale of individual equipment.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!