Vertical Roller Mill

Overview: Revolutionary Equipment for Modern Cement Processing

As a professional manufacturer of mobile crushing equipment for mining, we consistently focus on the latest technological advancements in downstream processing of mining raw materials. In cement production, the vertical roller mill is no longer just one option among many grinding devices, but represents the mainstream direction of efficient and energy-saving production in the modern cement industry. This highly efficient cement processing equipment has completely revolutionized traditional grinding processes, playing a core role in several key processes such as raw material preparation, coal powder preparation, and cement grinding.

In-depth Analysis: Technological Evolution and Application Expansion of Vertical Roller Mills

Since its large-scale application in the cement industry in the 1980s, the vertical roller mill has expanded from initial raw material grinding to multiple fields including cement, slag, and non-metallic minerals. Its technical principle is based on the material bed grinding theory, where pressure is applied to the grinding rollers through a hydraulic system, causing the material to be crushed between the grinding disc and the rollers. This innovative principle has led to a qualitative leap in grinding efficiency.

Core Advantages of Vertical Roller Mills in Cement Processing

Compared to traditional ball mill systems, vertical roller mills demonstrate significant advantages in multiple dimensions, becoming a key piece of equipment for modern cement plants to reduce operating costs and improve competitiveness.

Excellent Energy Saving and Consumption Reduction Capabilities

This is the most prominent advantage of the vertical roller mill. Due to its special material bed grinding principle, energy is directly applied to the material, resulting in extremely high energy utilization efficiency. Actual operating data shows that in raw material grinding applications, the power consumption of vertical roller mills can be 30-50% lower than traditional ball mill systems. For a standard 5000 t/d production line, this can save millions of yuan in electricity costs annually, significantly shortening the investment payback period.

Powerful Integrated Drying and Grinding Function

A large amount of hot air is introduced into the vertical roller mill, allowing for simultaneous grinding and drying operations. This integrated design enables it to process raw materials with a moisture content of up to 15-20%, making it particularly suitable for processing materials such as limestone and clay with a certain amount of moisture. This characteristic allows it to be directly matched with front-end mobile crushing equipment, maintaining stable operation even when the raw material moisture content is high. H3: High System Integration and Small Footprint

The vertical roller mill integrates multiple processes such as grinding, drying, and classification into a single piece of equipment, resulting in a simple and compact process flow. Compared to traditional ball mill systems, it reduces the footprint by 30-50%, lowering civil engineering investment, and is particularly suitable for use in factories with limited space or in old factory renovation projects.

Stable Product Fineness and Flexible Adjustment

By adjusting the classifier speed and system airflow, the product fineness can be flexibly controlled within a wide range, and the product particle size distribution is uniform and stable. This is of great significance for meeting the production requirements of different cement varieties and provides technical assurance for the production of high-performance cement.

| Key Words |

Dolomite Grinding Equipment |

| Product Model |

Vertical Roller Mill |

| Feed Size |

0-38mm |

| Capacity |

10-120t/h |

| Core Functions |

The crushing and grinding action of the rollers. |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Typical Case: Application of Vertical Roller Mill in a Modern Cement Production Line

In the complete raw material processing solution we provided to a large cement group in South Asia, we successfully demonstrated the perfect combination of the vertical roller mill and the mobile crushing system. The front end of the project uses a combination of a mobile jaw crusher and a mobile cone crusher to complete two-stage crushing of limestone at the mine site, with the crushed product particle size controlled within the range of 0-40mm.

Core process: After pre-homogenization, the crushed raw materials enter two large raw material vertical roller mills. Each vertical roller mill has a designed output of 320 t/h, and the actual operating power consumption is only 12.8 kWh/t, significantly better than the design specifications. The vertical roller mill system operates stably, with a product qualification rate of over 99.5%, providing a solid guarantee for the stable operation of the subsequent rotary kiln. This project has become a benchmark project for energy saving and consumption reduction in the region.

Equipment Matching and System Integration Suggestions

Mobile Crushing System: Including mobile jaw crusher and mobile cone crusher, providing raw materials with uniform particle size and reasonable gradation for the vertical roller mill, which is a prerequisite for ensuring the efficient and stable operation of the vertical roller mill.

Raw Material Pre-homogenization Equipment: Ensuring the uniform composition of raw materials entering the vertical roller mill is an important guarantee for producing qualified raw materials.

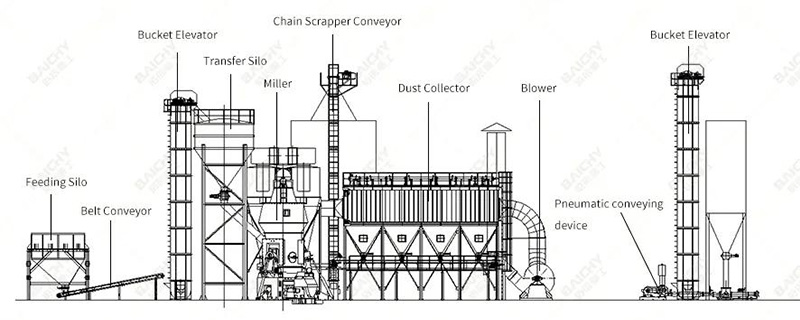

High-efficiency Dust Collection System: The bag filter matched with the vertical roller mill ensures that the system's dust emissions meet environmental protection requirements. Automated Control System: The advanced DCS control system enables automatic start-up and shutdown, parameter optimization, and fault diagnosis of the vertical roller mill system, improving operational reliability.

Mobile Jaw Crusher

Mobile Cone Crusher

DMC Pulse Dust Collector

Frequently Asked Questions

Q1: What are the main applications of vertical roller mills in cement plants?

A1: Vertical roller mills have three main applications in modern cement plants: raw material grinding (the most common application, processing mixed raw materials such as limestone, clay, and iron powder), coal powder preparation (for coal powder preparation in kilns and decomposition furnaces), and cement grinding (grinding clinker to produce cement, a relatively complex technology but with significant energy-saving contributions). With technological advancements, the application of slag vertical roller mills is also becoming increasingly widespread.

Q2: How to optimize the matching with upstream crushing equipment?

A2: The optimal feed size for vertical roller mills is usually 0-50mm. The upstream mobile crushing system requires two stages of crushing: primary crushing (usually using a jaw crusher) to crush the raw material to below 250mm, and secondary crushing (usually using a cone crusher or impact crusher) to further crush it to below 50mm. Appropriate particle size distribution not only increases the output of the vertical roller mill but also reduces unit power consumption. As a professional manufacturer of mobile crushing equipment for mining, we can provide complete crushing system solutions.

Q3: What are the key points for maintenance of vertical roller mills?

A3: Main maintenance includes: wear inspection and replacement of grinding rollers and grinding disc liners (depending on the material and material abrasiveness, the lifespan is usually 6000-10000 hours); regular inspection and maintenance of the hydraulic system; cleaning and maintenance of the lubrication system; and balance inspection of the classifier rotor. Modern vertical roller mills are usually equipped with an online monitoring system to monitor the equipment's operating status in real time, enabling predictive maintenance.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!