Having dedicated 20 years to the mining crushing equipment manufacturing industry, we deeply understand that while standardized equipment is readily available, systematic solutions are hard to come by. This is especially true when facing challenging working conditions such as preparing ultra-fine fuel from high-moisture coal (moisture content >20%). Selecting a single piece of equipment is insufficient; it requires a profound understanding of the entire process flow and system integration capabilities.

I. Why is ultra-fine crushing of high-moisture coal a challenge for the industry?

The client's core objective is to stably and continuously process high-moisture (>20%), large-particle (≤50mm) coal into ultra-fine powder with a D80 < 0.2mm for use as fuel. This is far beyond the capabilities of a single powerful crusher.

• Core conflict: The conflict between high viscosity and the requirement for high fineness. Moisture is the natural enemy of crushing; it causes material to adhere to the crushing chamber, screens, and conveying equipment, leading to severe blockages and shutdowns, resulting in failure to meet both production capacity and fineness requirements.

• Technical bottleneck: Traditional single-stage crushing or simple two-stage crushing solutions experience a sharp decline in efficiency when the moisture content exceeds 12-15%. Attempting to forcibly process the material with equipment marketed as blockage-proof often results in frequent maintenance and low output.

II. Three-stage progressive, graded processing

Based on 20 years of application data and engineering experience, we have developed and verified through numerous projects a golden rule: Pre-treatment crushing + efficient drying and dewatering + fine grinding and classification. This is a system engineering process with interconnected stages.

Process Flow Overview

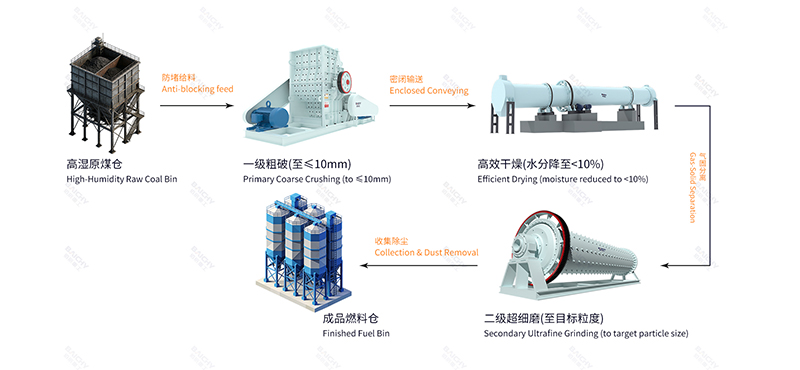

High-moisture raw coal silo → [Anti-blocking feeding] → Primary coarse crushing (to ≤10mm) → [Closed conveying] → Efficient drying (moisture reduced to <10%) → [Gas-solid separation] → Secondary ultra-fine grinding (to target particle size) → [Collection and dust removal] → Finished fuel silo.

Process Flow Overview

III. Analysis of Core Equipment Advantages: Targeted Selection Logic

High-Moisture Coal Ultrafine Crushing System Solution

First Stage: Breaking and Homogenizing – Double-Stage Crusher

As the pioneer of the system, its advantage lies in using the impact force of high-speed rotating chains to crush materials. It has a natural immunity to high-moisture and viscous materials, and the cavity design prevents clogging, providing uniformly sized raw materials for subsequent drying, serving as the first guarantee for stable production.

Second Stage: Dehumidification and Problem Solving – Cyclone Rotary Dryer

This is the core hub for solving fundamental problems. We recommend a hot-air rotary dryer integrated with high-efficiency lifting plates. Its advantages are sufficient heat exchange, large processing capacity, and stable operation. It can forcibly reduce the material moisture to the safe zone for crushing (below 8%), completely unleashing the capacity and precision potential of subsequent processes.

Third Stage: Precision Pulverization – European Trapezium Mill

For dried coal, achieving the stringent fineness of D80<0.2mm is beyond the capabilities of traditional Raymond mills. The European trapezium mill, as its revolutionary upgrade, adopts curved shovels, large-diameter grinding rollers, and a variable-frequency speed-regulating three-dimensional classification system, which can easily achieve precise adjustment and stable output of products between 0.038-0.18mm (80-400 mesh), and has lower energy consumption than air-flow mills, making it the optimal solution to meet your D99, D90, and D80 distribution requirements.

IV. Successful Case Study: 4 tons/hour High-Moisture Coal Pulverizing System

• Customer: A certain environmental fuel company in North China

• Challenge: Lignite raw material, moisture content 22%-28%, requiring finished product D90<0.5mm, used as boiler pulverized coal.

• Our Solution: Chain crusher + Φ1.5x12m rotary dryer + MTW175 European trapezium mill, with a complete set of anti-clogging feeding, dust removal, and electrical control systems.

• Operating Results: The system has been running stably for over 3 years, with an actual output of 4.5 tons/hour, product moisture content <6%, and D80 stable at around 0.18mm, fully meeting the customer's boiler combustion requirements. It has replaced the original production line which suffered from severe clogging, reducing maintenance costs by 60%.

V. System Extension Recommendations: Essential Supporting Equipment and Details

1. Intelligent Anti-Clogging Feeding System: Utilizes a heavy-duty plate feeder with variable frequency control to ensure uniform feeding from the source.

2. High-Efficiency Pulse Bag Dust Collection System: Configured throughout the entire process, especially at the drying and mill outlets, to ensure environmental compliance. Explosion-proof design is recommended for safety.

3. Integrated Electrical Control System: One-button start/stop, interlocking control, and remote monitoring enable intelligent operation with minimal human intervention.

VI. Frequently Asked Questions (FAQ)

Q1: Can a screenless, anti-sticking double-stage crusher be used to skip the drying step?

A1: This is highly unrecommended. While this type of equipment has some effect at low moisture levels (<15%), its anti-sticking capability quickly reaches its limit for coal with >20% moisture. Forcing its use will lead to internal cavity caking, coarse output, and a drastic drop in production, ultimately resulting in a total cost of ownership far higher than the drying + fine grinding system solution.

Q2: What heat source options are available for the drying process? Is the energy consumption high?

A2: Heat sources can include natural gas, diesel, biomass pellets, or a small hot air furnace (burning part of the finished coal powder). While the dryer does consume energy, the significant improvements in subsequent crushing efficiency, equipment stability, and product quality make the overall economics more favorable. We can design the most economical heat source solution based on your site conditions.

Q3: What are the investment and construction cycle for the entire system?

A3: As a turnkey project supplier, we provide a full range of services from design, manufacturing, installation to commissioning. For a 4-5 tons/hour system, the typical construction cycle is approximately 3-4 months. While the investment is higher than for a single machine, considering the lifespan of over 10 years, stable high-yield capacity, and extremely low downtime losses, it is a high-value long-term investment.