Discover the Integrated Drying & Crushing Solution

When Drying Meets High-Hardness Agglomeration: A Common Processing Trap

In industries such as mineral processing, ceramics, and glass micronization, drying finely ground filter cakes is a common post-processing step. However, many engineers encounter a troublesome problem: materials severely agglomerate during the drying process, and the resulting clumps are extremely hard, making them impossible to easily break up using conventional methods.

For example, a recent client inquiry we received highlighted their concerns regarding finely ground glass filter cakes. When evaluating a three-cylinder dryer, they expressed a similar concern: Can the glass be adequately broken up in a three-cylinder dryer? If it hardens after drying, will we need to purchase an additional crushing system?

This precisely addresses a core pain point in traditional drying processes: the disconnect between drying and crushing. Traditional rotary equipment like three-cylinder dryers primarily rely on heat conduction and convection. Their built-in chains or lifting plates are effective for the initial dispersion of soft, wet materials, but for materials with high surface tension, such as glass powder, quartz powder, and ceramic powder, which harden rapidly during dehydration, their crushing force is often insufficient. This ultimately leads to lengthy processes, increased energy consumption, and doubled equipment investment.

Simplifying Complexity: A Revolution from Dry First, Crush Later to Dry and Crush Simultaneously

As experts with 20 years of experience in solid waste treatment and mineral processing, our core concept is that for fine filter cakes prone to hardening, the optimal process path is to use integrated drying and crushing equipment.

This means that we need to apply strong mechanical shearing and dispersing forces during the material's most vulnerable wet stage, crushing it before it forms hard lumps and ensuring full contact with hot air for simultaneous drying. This not only yields a uniform dry powder product but also eliminates the need for expensive high-hardness crushing processes at the back end, achieving a one-stop solution that saves energy, space, and investment.

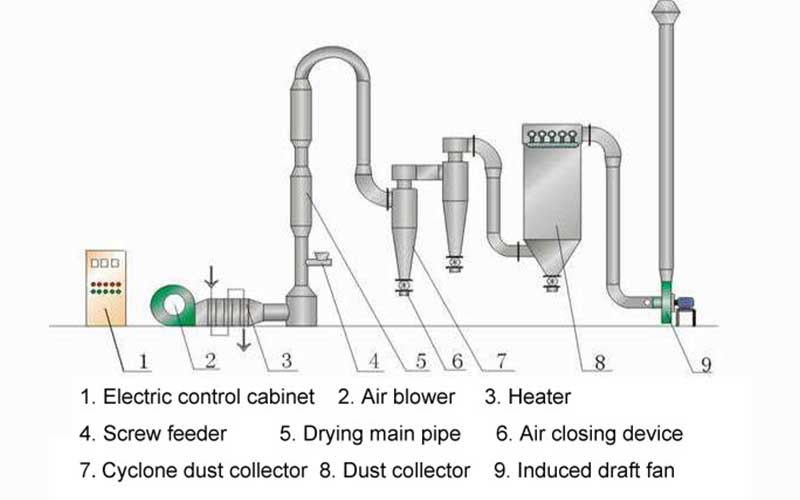

integrated-drying-and-crushing

Why is a flash dryer the ideal choice for such materials?

Among various drying equipment, the flash dryer (also known as a rotary high-speed dryer) perfectly meets the process requirements of drying and crushing simultaneously, and is particularly suitable for materials such as finely ground glass filter cakes, silica powder, aluminum hydroxide, and ceramic raw materials.

1. Powerful Crushing, Prevention is Better than Cure

The equipment is equipped with a high-speed rotating crushing rotor (adjustable speed) at the bottom. After the wet filter cake enters the drying chamber, it is first violently broken down and crushed by the hammers or blades on the rotor, decomposing it into fine particles before the material hardens internally due to heat.

2. Instant Drying, Superior Quality

The crushed fine particles are instantly enveloped by powerful high-temperature hot air, remaining in a suspended state, achieving maximum specific surface area and extremely rapid heat and mass transfer. The short material residence time avoids overheating, making it particularly suitable for heat-sensitive materials and yielding a uniform dry powder with good flowability.

3. Streamlined Process, Lower Overall Cost

A single unit integrates crushing, drying, and grading. Compared to a combination of a three-cylinder dryer + jaw crusher/double-roller crusher, it significantly reduces equipment investment, floor space, energy consumption, and labor costs, while offering a smoother process and a high degree of automation.

Proven Success from the Glass Micropowder Industry

We solved the exact same problem you described for a specialty glass powder manufacturer.

• Client Pain Points: Aluminum hydroxide filter cake hardened and agglomerated after drying, requiring an additional crushing line; product particle size was uneven, resulting in high energy consumption.

• Our Solution: We used a large-scale, intensified flash dryer, customizing the rotor structure, speed, and drying temperature profile specifically for the material characteristics.

• Superior Results:

◦ Feed: Filter cake with a moisture content of ~35%.

◦ Output: Uniform ultrafine powder with a moisture content of <0.5%, with over 80% of particles passing through a 325-mesh screen.

◦ Completely eliminated post-drying agglomeration, eliminating the need for any post-crushing equipment.

◦ The client was highly satisfied with the product uniformity and system energy consumption.

Related Equipment Recommendations

In addition to flash dryers, depending on the material viscosity and initial state, you may also consider:

• Disc dryer (with crushing device): Suitable for paste-like materials with higher viscosity that require longer residence times for conduction drying.

• Spray dryer: Suitable for solutions or slurries, directly drying into powder, but energy consumption is relatively high.

We strongly recommend that you provide a 1-2 kg sample of your material for a free drying test at our testing center. Verifying equipment selection with real experimental results is the most scientific way to mitigate risk.

Frequently Asked Questions (FAQ)

1. What particle size feed can a flash dryer handle?

Flash dryers are primarily used for pumpable paste-like filter cakes or slurries. For large solids, pre-crushing is required. For your finely ground glass filter cake, its physical state is well-suited for direct feeding.

2. How is the particle size of the dried product controlled?

The fineness of the product can be effectively controlled by adjusting the speed of the classifier at the bottom of the drying tower. Finer particles are carried away and collected by hot air, while coarser or incompletely dried particles are blocked by the classifier for further drying and crushing, thus ensuring the uniformity of the final product.

3. How does its energy consumption compare to a three-cylinder dryer?

Flash dryers are a type of convective drying, ensuring ample contact between hot air and the material, resulting in high thermal efficiency. Although the inlet temperature may be higher, the extremely short residence time (a few seconds) means that the total energy consumption is typically better than or equivalent to the combined energy consumption of a drying + post-crushing system. Furthermore, the shorter process length leads to lower system losses.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!