Secondary Cone Crusher Machine

In the sand and gravel aggregate and mineral processing industry, the secondary crushing stage directly determines the final product's output, particle shape, and cost-effectiveness. A high-performance secondary cone crusher is not only the heart of the production line but also the key to improving product quality and gaining a competitive edge in the market. This article will provide a comprehensive understanding of how secondary cone crushers solve production pain points and how their superior performance creates real value for you.

Looking for optimized secondary crushing solutions?

Are you also facing these challenges in your crushing production?

In today's pursuit of higher capacity and better efficiency, traditional secondary crushing solutions often fall short. Are you troubled by the following problems?

• Low crushing efficiency and high energy costs: Insufficient equipment processing capacity and low output per unit of electricity consumption lead to high costs per ton, directly eroding profit margins.

• Uneven finished product particle shape and reduced product value: High content of needle-like and flaky aggregates and unsatisfactory gradation fail to meet the demands of high-end construction materials, making it difficult to increase selling prices.

Frequent downtime and high maintenance costs: Poor equipment stability, frequent unexpected shutdowns, and complex, time-consuming repairs not only affect delivery but also overwhelm the maintenance team.

These problems are hindering your development. The solution lies in an advanced two-stage cone crusher.

How can a two-stage cone crusher be the key to breaking these bottlenecks?

The two-stage cone crusher is specifically designed for medium and fine crushing of medium-hard and harder ores. Through the principle of layered crushing, it efficiently further crushes the material from the primary crushing stage to the required particle size, making it a standard configuration for modern stone production lines.

Its core value lies in its optimized structural design and intelligent control system, which simultaneously overcomes the three major challenges of efficiency, particle shape, and stability, providing you with a stable, high-yield, and high-quality crushing solution, fundamentally improving the overall efficiency of your production line.

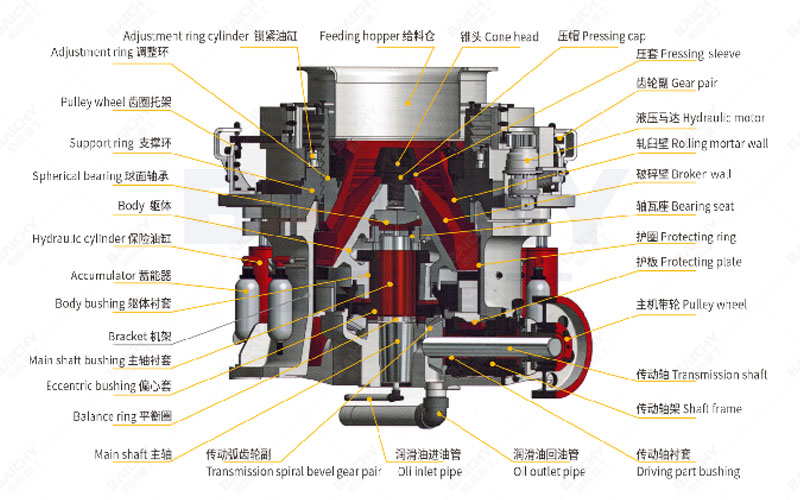

Internal structure diagram of a hydraulic cone crusher

Working Principle and Key Characteristics of a Two-Stage Cone Crusher

Working Principle

The material falls from the feed inlet into the crushing chamber formed by the moving and stationary cones. Driven by an eccentric sleeve, the moving cone oscillates, compressing, impacting, and bending the material to achieve continuous lamination crushing. Material meeting the particle size requirements is discharged from the bottom under gravity.

Key Features

1. Hydraulic Adjustment and Iron Overload Protection: An advanced hydraulic system allows for easy adjustment of the discharge port size to control product particle size. When uncrushable foreign objects (such as iron blocks) enter the chamber, the hydraulic system automatically depressurizes, protecting the core components of the main unit from damage.

2. Lamination Crushing Chamber Design: Optimized chamber design for different material characteristics (such as hardness and moisture content) ensures multi-particle crushing during the crushing process, significantly improving processing capacity and the proportion of cubic finished products.

3. Heavy-Duty Design and Superior Materials: Utilizing a high-strength cast steel frame and high-wear-resistant alloy steel liners ensures long-term stable operation under harsh conditions and extends the service life of core components.

Beyond the Specifications: Real Benefits

Choosing a superior two-stage cone crusher offers more than just a cold machine; it brings tangible improvements in efficiency:

• Advantage 1: Higher Production Efficiency and Lower Energy Consumption per Ton

◦ Value Brought to You: The layered crushing principle allows the equipment to produce more at the same power level, directly reducing the electricity cost per ton of aggregate, achieving increased production and reduced consumption.

• Advantage 2: Superior Finished Particle Shape and Higher Product Price

◦ Value Brought to You: The produced aggregate has a high cubic content, continuous gradation, and significantly reduced needle-like and flaky content. This high-quality aggregate is more competitive in the market and can fetch a better price.

• Advantage 3: Excellent Stability and Convenient Maintenance, Saving Downtime Costs

◦ Value Brought to You: The hydraulic clearing function makes daily inspection and maintenance quick and simple; the overload release function avoids long-term downtime due to unexpected malfunctions. This means less unplanned downtime and higher personnel efficiency.

• Advantage 4: Intelligent Control System

◦ Value it Brings: It can be integrated with an automatic control system to monitor operating status and adjust parameters in real time, achieving intelligent production, reducing reliance on operator experience, and ensuring production is always at its optimal state.

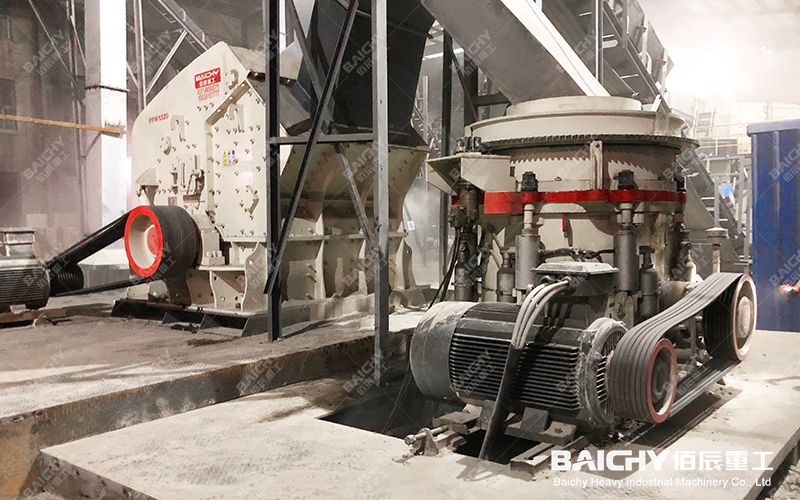

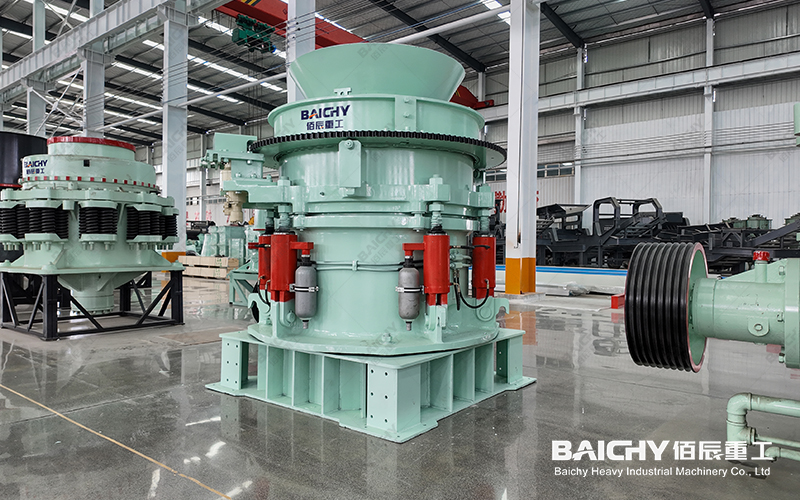

Hydraulic cone crusher on-site operation diagram

Successful Cases/Application Scenarios: Data is the Best Proof

• Case Study: A Large Granite Quarry

◦ Challenges: The original production line used a jaw crusher + impact crusher scheme. When producing high-grade concrete aggregate, the needle-like and flaky content of the finished product exceeded the standard (>18%), and the impact crusher hammers wore out extremely quickly, resulting in high maintenance costs.

◦ Solution: Our HPM300 multi-cylinder hydraulic cone crusher was adopted as the secondary crushing equipment.

◦ Results: The needle-like and flaky content of the finished aggregate was reduced to <10%, fully meeting the high standard requirements; the equipment operated stably, and the liner service life exceeded 600 hours; the overall production cost per ton was reduced by approximately 15%. Learn more about us by clicking on the specific case study page.

How to Choose and Match a Secondary Cone Crusher

Choosing the right secondary cone crusher requires considering the following factors:

1. Material Characteristics: Hardness, abrasiveness, moisture content, feed size.

2. Capacity Requirements: Desired hourly output.

3. Finished Product Requirements: Target particle size and shape requirements.

4. Production Line Compatibility: Compatibility with upstream feeders, primary jaw crushers, and downstream equipment such as vibrating screens and sand making machines.

We recommend communicating with our technical engineers. We will provide optimized design solutions, from single machines to complete crushing and screening production lines, based on your specific operating conditions.

Frequently Asked Questions (FAQ)

What are the main advantages of a secondary cone crusher compared to an impact crusher?

Cone crushers are more suitable for crushing medium-hard, highly abrasive materials, have longer wear-resistant parts life, lower operating costs, and produce finished products with better particle shape. Impact crushers are more suitable for medium-low hardness materials, with advantages including lower price and more flexible product adjustments.

How often do the wear parts (such as liners) of the equipment typically need to be replaced?

This depends on the abrasiveness of the material being crushed and the equipment's operating time. Generally, manganese steel liners have a service life of 400-800 hours. Long-life liners with a symmetrical design can be rotated for use, further extending the replacement cycle.

Can the crushing chamber shape be changed to adapt to different production needs?

Yes. Many modern cone crushers offer a variety of chamber shape options (such as standard, coarse, and fine). By changing the corresponding liners, the geometry of the crushing chamber can be adjusted to adapt to different feed and product requirements, achieving multi-purpose functionality.

The secondary cone crusher is the core of a modern, high-efficiency crushing production line. Its superior performance has irreplaceable value in improving efficiency, optimizing product quality, and reducing long-term operating costs. Investing in a technologically advanced cone crusher is a solid guarantee for your company's future profitability.

Take action now and let our professional team evaluate the best solution for you!

• Get a free equipment selection guide and quote

Schedule a consultation with a technical engineer for one-on-one production line design solutions