Hydraulic Cone Crusher | Factory Price

In the sand and gravel aggregate and mining processing sector, where higher production efficiency is sought, are you troubled by efficiency bottlenecks and operating costs? As the core equipment in the medium and fine crushing stage, the hydraulic cone crusher, with its superior performance and intelligent control, is completely changing the traditional crushing operation mode. This article will give you a comprehensive understanding of how it has become a key tool for enhancing competitiveness and achieving cost reduction and efficiency improvement.

Common Pain Points in Traditional Crushing Operations

In the fierce market competition, many quarries and mining operators are facing a series of severe challenges:

• Low Crushing Efficiency: The efficiency of the medium and fine crushing stage after the old-fashioned spring cone crusher or jaw crusher is low, with low output per unit of energy consumption, restricting the capacity of the entire production line.

• Unsatisfactory Finished Material Shape: The produced aggregate has an excessively high content of needle-like and flaky particles, and uneven particle shape, making it difficult to meet the stringent requirements for aggregate quality in high-grade construction, commercial concrete, and infrastructure projects, resulting in low product prices.

• High and time-consuming maintenance costs: When equipment malfunctions such as material blockage or excessive iron flow, the cleaning and repair process is cumbersome, requiring significant manpower and time, resulting in long unplanned downtime and substantial losses.

• Inconvenient adjustments and inflexible product particle size control: Adjusting the discharge port size to adapt to different product requirements is complex, imprecise, and unable to quickly respond to market changes.

Overview of Hydraulic Cone Crusher

To address these challenges, the hydraulic cone crusher was developed. It integrates mechanical, hydraulic, electrical, and intelligent control technologies, providing a perfect solution for efficient, stable, and controllable crushing operations through an advanced hydraulic system and crushing chamber design. It not only improves crushing efficiency but also achieves a qualitative leap in finished product quality, equipment maintenance, and automation levels.

In-depth analysis: Working principle and key characteristics of the hydraulic cone crusher

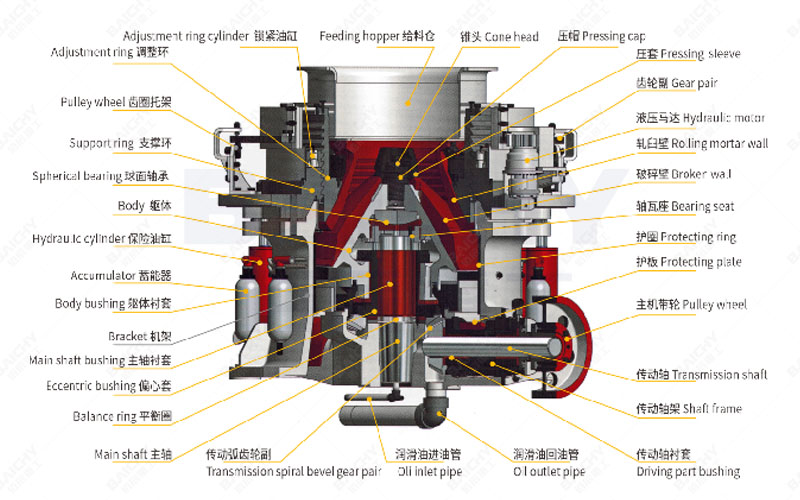

1. Core working principle: The hydraulic cone crusher uses an electric motor to drive a horizontal shaft to rotate. The horizontal shaft, through gears, drives the eccentric sleeve assembly to rotate, causing the moving cone to oscillate within the fixed cone liner. Material is crushed within the crushing chamber by frequent compression and bending of the moving cone. Its core lies in utilizing a hydraulic system to replace traditional mechanical springs, achieving functions such as overload protection and discharge port adjustment.

2. Key Characteristics and Technical Details:

• Hydraulic System: This is where its intelligence lies. The hydraulic cylinder not only adjusts the discharge port size but, more importantly, provides overload protection. When uncrushable materials (such as iron blocks) enter the chamber, the hydraulic system instantly depressurizes, enlarging the discharge port to expel it, and then automatically resets, protecting the core components of the equipment.

• Layered Crushing Principle: The optimized crushing chamber design makes the crushing process primarily layered crushing. Material is subjected to multiple, orderly compression and impacts within the chamber, rather than single-point impacts, which greatly improves crushing efficiency and ensures a high cubic content in the finished product.

• Fixed Main Shaft Structure: Compared to older equipment, modern hydraulic cone crushers often adopt a structure with a fixed main shaft and an eccentric sleeve rotating around it, resulting in more stable movement, stronger load-bearing capacity, and longer equipment lifespan.

• Intelligent Control System: Integrates with an automatic control system, monitoring parameters such as spindle position, lubricating oil temperature, pressure, and output in real time. Enables remote control and fault diagnosis, laying the foundation for unmanned factories.

Core Advantages and Value: Transformation from Features to Benefits

| Features | Practical benefits for you |

| Hydraulic Overload Protection and Cavity Clearing Function | Significantly Reduces Unexpected Downtime Risk: When encountering uncrushable materials, the equipment automatically handles them, eliminating the need for manual cavity clearing as required by traditional equipment. This saves you valuable time and ensures continuous production. |

| Hydraulic Adjustable Discharge Port | Quickly Responds to Market Demands: Precisely adjust the discharge particle size with simple button operation in the control room, easily switching between different product specifications. This helps you seize market opportunities and improve product flexibility. |

| Laminated Crushing and Optimized Cavity Shape | Enhances Product Value and Output: Produces aggregate with excellent particle shape and low needle-like/flaky content, suitable for direct sale as high-end commercial aggregate at a higher unit price. Simultaneously, the laminated crushing efficiency is higher, significantly increasing output with the same power consumption. |

| Centralized Lubrication and Intelligent Monitoring Reduce Maintenance Intensity and Costs | Automatic lubrication of key components via the lubrication system and early warning of potential faults by the intelligent system transform passive maintenance into preventative maintenance, reducing sudden failures, extending equipment lifespan, and lowering overall operating costs. |

Successful Cases/Application Scenarios

• Scenario 1: Large-Scale Granite Aggregate Production Line

◦ Challenge: A large Southeast Asian building materials group needs to build a high-quality aggregate production base with an annual output of tens of millions of tons, placing extremely high demands on equipment reliability, finished product particle shape, and automation.

◦ Solution: Multiple high-capacity hydraulic cone crushers were used to form the core of the medium and fine crushing process.

◦ Results: The production line operates stably, the finished aggregate has a cubic particle shape and excellent gradation, and the product sells well in the high-end market. The average mean time between failures (MTBF) exceeds 3000 hours, and the intelligent control system reduces unit energy consumption by approximately 15%.

• Scenario 2: Fine Crushing Operations in Metal Mines

◦ Challenge: An iron ore beneficiation plant's existing fine crushing equipment suffers from rapid wear and frequent maintenance, affecting beneficiation capacity.

◦ Solution: A wear-resistant hydraulic cone crusher was selected for the final fine crushing of the ore.

◦ Results: When crushing high-hardness iron ore, the equipment exhibited excellent wear resistance, extending liner life by 30%. The hydraulic adjustment function ensured stable discharge particle size, creating favorable conditions for subsequent grinding processes, and increasing overall plant capacity by approximately 10%.

Selection and Matching Recommendations

Choosing the right hydraulic cone crusher is crucial for success. You need to consider the following:

1. Material Characteristics: Hardness, moisture content, mud content, and maximum feed size are primary factors. High-hardness materials require heavy-duty equipment with a focus on wear resistance.

2. Capacity Requirements: Select the appropriate model based on your production line's designed output, allowing for a 10%-15% margin to handle peak demand.

3. Product Requirements: For extremely high requirements on aggregate particle shape, priority should be given to models with multiple cavity options and optimized for particle shape.

4. Automation Level: For intelligent, low-staff production, it is essential to choose brands and equipment equipped with advanced intelligent control systems.

5. System Integration: Hydraulic cone crushers are typically used as secondary or tertiary crushing equipment and need to work in conjunction with jaw crushers (for coarse crushing), feeders, vibrating screens, conveyors, etc. It is recommended to seek comprehensive solutions from professional manufacturers to ensure smooth and efficient production lines.

Frequently Asked Questions about Hydraulic Cone Crusher

1. What is the main difference between a hydraulic cone crusher and a spring cone crusher?

The main difference lies in the safety and adjustment devices. Spring cone crushers rely on mechanical springs for overload protection, while hydraulic cone crushers use a hydraulic system, resulting in faster response, quicker reset, and remote adjustment of the discharge port via a hydraulic device, leading to a higher degree of automation.

2. Is the energy consumption of a hydraulic cone crusher high?

On the contrary, modern, high-efficiency hydraulic cone crushers, due to their layered crushing principle, have a much higher energy utilization rate than traditional impact crushers, often consuming less energy for the same output. Their intelligent control systems can also optimize operating conditions based on load, further saving energy.

3. What aspects should be considered in daily maintenance?

The core of daily maintenance is lubrication and inspection. Regularly check the lubricating oil level and cleanliness to ensure the lubrication system is working properly; regularly check the wear of vulnerable parts such as liners and replace them promptly to ensure crushing efficiency and product particle size. The good news is that advanced equipment is equipped with online monitoring systems, which can greatly simplify maintenance work.

With its superior performance of high efficiency, intelligence, reliability, and ease of maintenance, the hydraulic cone crusher has become an indispensable core equipment in the modern aggregate and mineral processing field. It is not only a tool to solve current production pain points, but also a strategic investment for you to move towards intelligent production and enhance market competitiveness.

If you are planning a new production line or wish to upgrade your existing crushing system, our team of experts is ready to serve you. We will provide the most cost-effective equipment selection and overall solutions based on your specific materials, production capacity, and budget.

Take action now! Contact us for a free customized solution design and detailed quotation, or click to download the hydraulic cone crusher product brochure to learn more about the technical parameters!