Sand Washing And Dewatering Integrated Equipment

I. The Era's Demand for Clean Sand and Aggregate

In today's mining, building materials, and infrastructure construction sectors, high-quality manufactured sand is the core aggregate that guarantees project quality. Traditional sand washing and dewatering processes often require multiple pieces of equipment in series, resulting in a large footprint, high investment costs, and complex operation and management. Facing upgrading market demands and increasingly stringent environmental policies, integrated sand washing and dewatering equipment has emerged, becoming the ultimate solution for "improving quality, increasing efficiency, and achieving environmental protection" in sand production lines.

| Key Words | Sand Washing And Dewatering Integrated Equipment |

|---|---|

| Product Model | Sand Washing And Dewatering Integrated Equipment |

| Feed Size | ≤10mm |

| Motor Power | 1.6-15KW |

| Capacity | 30-250t/h |

| Core Functions | It features integrated functions for cleaning, grading, dewatering, and fine sand recovery. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

II. What is Integrated Sand Washing and Dewatering Equipment?

Integrated sand washing and dewatering equipment, as the name suggests, is an innovative machine that highly integrates the functions of sand washing, dewatering, grading, and recycling into a single unit. It breaks the traditional model of separate sand washing machines, fine sand recovery machines, and dewatering screens. Through clever structural design, it completes the entire process from raw material cleaning to finished sand discharge on a single platform.

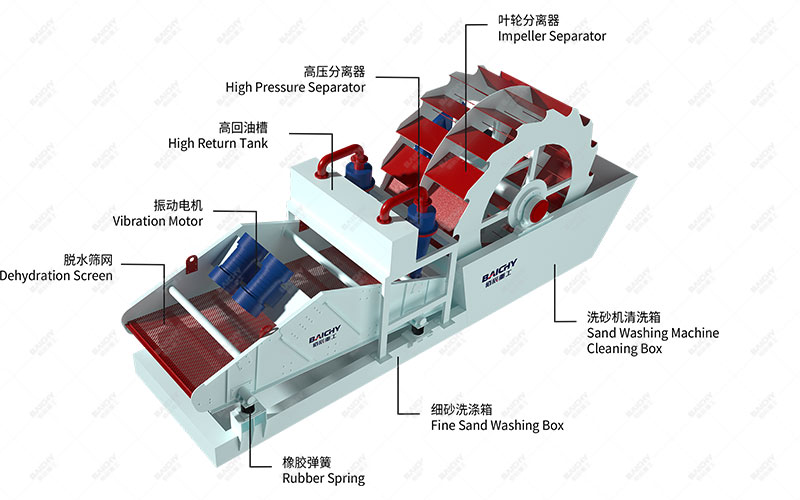

Structural-diagram-of-the-sand-washing-and-dewatering-integrated-equipment

Core Working Principle

The equipment mainly combines an impeller drive device, a screening device, and a dewatering device. During operation, the material tumbles and grinds under the drive of the impeller, effectively separating mud and impurities from the surface of the sand and aggregate. The cleaned sand particles are graded under the action of the rising water flow and screen mesh. Fine sand is effectively recovered, while coarse sand undergoes high-frequency vibration on the dewatering screen surface, achieving efficient dewatering and fine material filtration, ultimately producing clean, high-quality finished sand with low moisture content.

III. Significant Advantages: Why Has It Become the Industry's New Favorite?

As a manufacturer with 20 years of experience, we deeply understand our customers' pain points. This integrated equipment embodies the following advantages:

(I) Excellent Process and Performance Advantages

• High Efficiency and Cleanliness: Powerful washing and fine dewatering are completed simultaneously, resulting in finished sand with low mud content and reasonable gradation, far exceeding national standards.

• Low Moisture Content: The unique dewatering design allows the moisture content of the finished sand to be stably controlled between 8%-15%, making it ready for direct use or sale.

• Fine Sand Recovery: The built-in high-efficiency recovery system effectively controls fine sand loss, increasing the sand production rate by 5%-10%. (II) Outstanding Economic and Environmental Benefits

• Investment Savings: One piece of equipment replaces multiple production lines, saving on equipment purchase costs, infrastructure costs, and power installation costs.

• Economical Operation: Compact structure, lower energy consumption, reduced maintenance requirements, and significantly lower overall operating costs.

• Green and Environmentally Friendly: Achieves efficient separation of mud, water, and sand, and the sand washing water can be recycled, meeting environmental protection requirements.

IV. Application Cases: Verification from the Field

Our integrated equipment has been successfully applied in several large-scale sand and aggregate projects and construction waste recycling projects across the country.

Sand Washing And Dewatering Integrated Equipment

Case Study: A Large Green Building Materials Production Base in East China

The client's original production line used a traditional spiral sand washing machine + fine sand recovery machine combination, which suffered from limited space, serious fine sand loss, and high moisture content in the finished sand. After adopting our integrated sand washing and dewatering equipment, the processing capacity increased by 30% in the same footprint, the fineness modulus of the finished sand was stable, and the moisture content was reduced to below 12%. The economic benefits from reducing fine sand loss and lowering dewatering costs alone exceeded one million yuan annually.

V. Recommended Related Equipment: Building the Optimal Production Line

To maximize the efficiency of the integrated sand washing and dewatering equipment, we recommend combining it with the following star products from our company to form a winning combination:

• Jaw Crusher (Coarse Crushing): Provides stable raw materials for subsequent processes.

• Multi-cylinder Hydraulic Cone Crusher (Medium and Fine Crushing): Produces intermediate aggregates with excellent particle shape.

• Vibrating Feeder and Screening Equipment: Ensures uniform and continuous material flow into the sand washing equipment.

VI. Frequently Asked Questions (FAQ)

Q1: Compared with the traditional sand washing machine + dewatering screen combination, how much money can the integrated equipment actually save?

A1: The savings are systemic. Preliminary estimates show savings of approximately 20-30% in equipment purchase costs, and approximately 30-40% in installation and civil engineering costs. In the long term, due to its low energy consumption and fewer maintenance points, annual operating and maintenance costs can be further reduced by 15-25%.

Q2: Does the equipment have requirements for the particle size of the processed materials?

A2: There is an optimal applicable range. This equipment is primarily designed for cleaning and dewatering fine particulate materials ranging from 0-10mm (especially 0-5mm), achieving optimal results. For materials with high clay content and significant particle size variations, we recommend pre-screening with a fine screen to achieve the most ideal operating conditions.

Q3: How durable is your equipment? What is the lifespan of the key components?

A3: Benefiting from 20 years of experience in heavy machinery manufacturing, our equipment's key components, such as impellers, screens, and vibration motors, are made of high-wear-resistant materials or from well-known brands. Under normal operating conditions and maintenance, the core wear parts can last for 6-12 months or more. The overall structure is robustly designed to ensure long-term stable operation of the equipment.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!