Sand Washing With Dewatering Machine

What is a sand washing machine with dewatering function?

In wet processing lines for mining, sand and aggregate, and building materials industries, sand washing machines are indispensable key equipment. They are responsible for removing mud, stone powder, and other impurities from the surface of sand and gravel, improving material quality. However, traditional sand washing machines often face a common problem: the washed sand has a high moisture content (usually 15%-25%), which not only affects the quality of the finished product but also increases transportation costs and storage difficulties, and can even freeze in cold regions.

Sand washing machines with dewatering function are innovative products designed to solve this problem. They integrate an efficient dewatering screen or dewatering bucket into the traditional wheel-type or spiral-type sand washing machine, achieving integrated "washing-dewatering" operation. The moisture content of the discharged sand can be effectively reduced to 8%-15%, significantly improving the grading and quality of the finished sand, directly meeting high-quality sand standards.

| Key Words | Sand Washing With Dewatering Machine |

|---|---|

| Product Model | Sand Washing And Dewatering Integrated Equipment |

| Feed Size | ≤10mm |

| Motor Power | 1.6-15KW |

| Capacity | 30-250t/h |

| Core Functions | It features integrated functions for cleaning, grading, dewatering, and fine sand recovery. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Core Advantages: Why choose an integrated dewatering sand washing machine?

Compared with the traditional "sand washing machine + separate dewatering screen" configuration, the integrated sand washing machine with dewatering function has several significant advantages.

1. Saves space and infrastructure costs

The compact equipment structure integrates two processes into one machine, reducing the length of the production line layout and the number of equipment, thus lowering civil engineering and plant investment.

2. Reduces energy consumption and operating costs

The integrated design reduces material transfer and lifting steps, lowering the power consumption of auxiliary equipment such as belt conveyors. At the same time, centralized control simplifies operation and reduces labor costs.

3. Improves finished sand quality and value

Through powerful dewatering, the loss of fine sand is effectively controlled, and the sand grading is adjusted, making the finished sand particles cleaner and more uniform in size, greatly increasing the added value and market competitiveness of the product.

4. Achieves water resource recycling

Most models are equipped with a fine sand recovery device and a sewage sedimentation and circulation system. While achieving efficient dewatering, it also realizes the recycling of washing water, saving water resources and meeting environmental protection requirements.

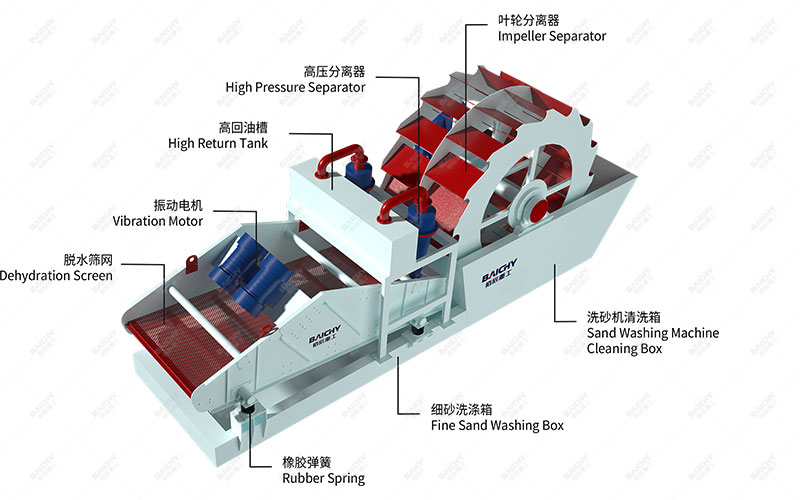

Structural-diagram-of-the-sand-washing-and-dewatering-integrated-equipment

Working Principle and Typical Application Cases

Brief Description of Working Principle

Taking a common wheel-bucket type dewatering and sand washing machine as an example, the material first enters the washing tank. Driven by the impeller, the material tumbles and grinds, separating impurities. The cleaned sand and gravel are then slowly lifted by the impeller. During this process, the sand particles are compressed against each other, expelling some of the water. Finally, the material is sent to the top dewatering screen for high-frequency vibration dewatering, further filtering out water and very fine particles, resulting in clean, low-moisture finished sand.

Sand Washing With Dewatering Machine

Successful Case Sharing

Case Study: A Large Green Building Materials Production Base in East China

This customer's original production line used traditional sand washing machines, resulting in high mud content and high moisture content in the finished sand, which affected the application of manufactured sand in commercial concrete. Our company recommended the LZ series wheel-bucket type dewatering and sand washing machine.

• Results after modification:

◦ The moisture content of the finished sand was stably reduced from 22% to below 10%.

◦ The loss rate of fine sand (below 0.16mm) was reduced by more than 70%, and the gradation was optimized.

◦ The production line layout is more compact, and energy consumption is reduced by approximately 18%.

◦ The product successfully entered local high-end commercial concrete mixing plants, and the selling price increased.

Equipment Selection and Related Recommendations

Choosing a suitable sand washing machine with dewatering function requires comprehensive consideration of material characteristics (particle size, mud content), processing capacity, site conditions, and finished product requirements.

| Model Recommendation | Applicable Materials | Processing Capacity Advantages | Brief Description of Features |

| LZ Series Wheel-Bucket Type | Medium and fine-grained sand and gravel (0-10mm) | Large processing capacity, high cleaning efficiency | Simple structure, easy maintenance, good dewatering effect, widest market application. |

| LX Series Spiral Type | Materials containing difficult-to-wash materials (such as crushed stone, slag) | Strong cleaning power | The material is propelled by spiral blades, resulting in a longer cleaning time, effective removal of stubborn mud and impurities, and also features dewatering function. |

| Mobile Dewatering Sand Washing Machine | Projects with dispersed sites and requiring relocation | Flexible and convenient |

Frequently Asked Questions (FAQ)

1. Can the dewatering sand washing machine guarantee the moisture content of the sand?

Yes, under stable operating conditions of feed particle size, mud content, and water volume, the equipment can guarantee that the sand moisture content is within the promised range (usually 8%-15%). The actual value may fluctuate slightly due to the original characteristics of the material. Our engineers will optimize it to the best state during commissioning.

2. Will the equipment cause a large amount of fine sand loss?

No. High-quality integrated machines are designed with fine sand recovery in mind. They usually have a fine sand recovery hydrocyclone or a sedimentation tank under the dewatering screen to recover the overflowed mud and fine sand mixture, ensuring controllable fine sand modulus and reducing resource waste.

3. How does the maintenance cost compare to traditional separate equipment?

The maintenance points of integrated equipment are relatively concentrated, usually in the transmission part, screen mesh, and bearing seals. Due to its simplified structure, daily maintenance such as lubrication, tightening, and screen replacement is simpler than maintaining two independent production lines. In the long run, maintenance costs and downtime are lower.

As a mining equipment manufacturer with 20 years of experience, we deeply understand the importance of sand and gravel cleaning and dewatering to your overall production efficiency. Choosing a reliable sand washing machine with dewatering function is not just buying equipment, but investing in higher product quality, lower operating costs, and a more sustainable production method. Welcome to contact us anytime for a customized solution.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!