Magnetic Separator

Introduction: A Single Device Is Not Enough – Why a “System-Level” Solution is Needed?

In modern mining and aggregate production, the value of mobile crushing plants lies in their high output and flexibility. However, the threat posed by unforeseen metal contaminants in the raw materials (such as shovel teeth, drill bits, blasting cable remnants, and rebar) is systemic. An isolated magnet may not be able to handle all challenges. Metals can be introduced from different locations and in different ways. Therefore, the concept of a magnetic separation system has emerged – it is no longer a single device, but a collaborative solution tailored to your specific material flow, threat level, and budget, designed to provide comprehensive protection for the entire production line.

| Key Words |

HGM60 Micro Powder Mill Supplier |

| Product Name |

Magnetic Separator |

| Magnetic field intensity (oe) |

1450-1650 |

| Motor Power |

1.1-11kw |

| Capacity |

8-200t/h |

| Core Functions |

By utilizing the magnetic differences between materials, magnetic and non-magnetic substances can be separated in a non-uniform magnetic field. |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

What is a Magnetic Separation System?

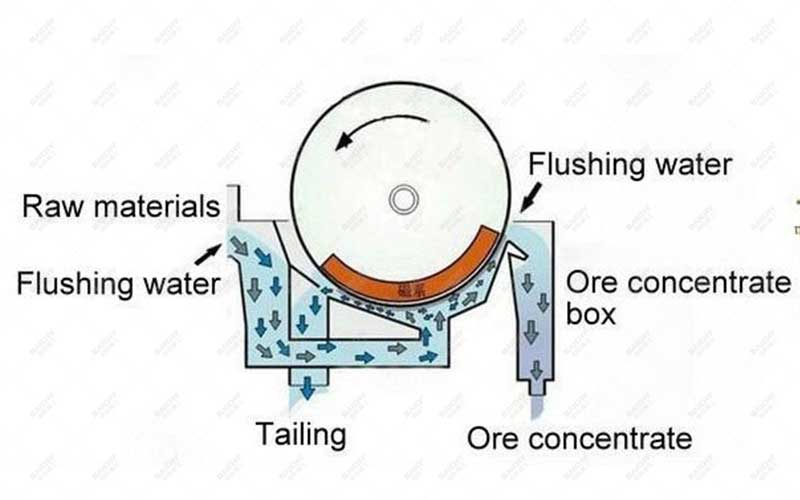

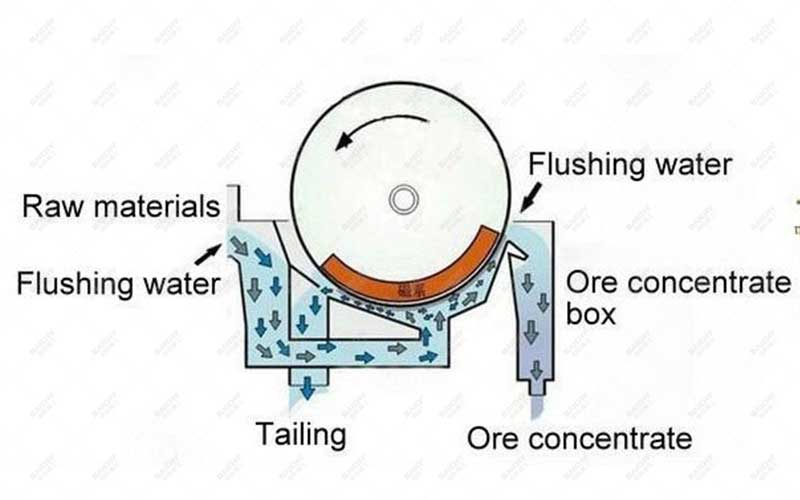

A magnetic separation system refers to the strategic deployment of different types and functions of magnetic separation equipment at multiple critical points in the material processing flow, thus forming a multi-layered, three-dimensional metal removal network. This system typically integrates various devices such as suspended magnetic separators, magnetic head pulleys (magnetic drums), and pipeline magnetic separators, which work together to ensure that metal contaminants are identified and removed to the greatest extent possible, from the feed before primary crushing to the final product loading. A well-designed system can handle metal threats of different sizes, burial depths, and magnetic properties.

Four Strategic Advantages of Integrating a Magnetic Separation System into Mobile Crushing Plants

1. 360-Degree Protection and Maximized Return on Investment

Layered Defense: Removing large metal pieces at the primary feed end (protecting the jaw crusher), and removing small and medium-sized metals before secondary and tertiary crushing (protecting the cone crusher and impact crusher), forming a layered defense system.

Comprehensive Benefits: Not only does it prevent damage to the expensive core components (rotors, liners) of the crusher, but it also protects downstream screens, conveyor belts, and material bins, achieving optimal life-cycle costs.

2. Improved Final Product Quality and Consistency

Purity Assurance: Systematic metal removal ensures that the produced aggregates or mineral products meet the strictest purity standards, which is crucial for obtaining premium prices, especially in high-end concrete aggregates and specific mineral processing.

Stability: Consistent and stable material composition makes it easier to optimize crushing process parameters, resulting in a more uniform product particle size.

3. Enhanced System Automation and Reliability

Intelligent Integration: Modern systems can be equipped with metal detection linkage, automatic iron removal, and remote monitoring functions, enabling unmanned operation and seamless integration with the intelligent control system of mobile crushing plants.

Reduced Unplanned Downtime: Unplanned, disruptive emergency shutdowns are transformed into planned, simple iron removal maintenance, significantly improving equipment availability.

4. Flexible and Scalable, Adapting to Future Changes

Modular Design: The system can be customized according to the current production line configuration (such as open or closed circuit) and includes reserved upgrade interfaces. Modules can be easily added or upgraded when processing materials or capacity changes.

Actual Application Scenarios and System Construction Cases

Typical System Configuration Scenarios

Scenario A: Granite/Basalt Mine

Challenge: Raw materials contain hidden drill bit fragments and mechanical parts.

System Solution: Above the feeder (suspended strong magnetic iron separator) + at the head of the conveyor belt after primary crushing (magnetic head pulley). This forms a "two-stage" defense line.

Scenario B: Construction and Demolition Waste Recycling

Challenge: Complex material composition, containing a large amount of rebar, wire mesh, and light metals.

System Solution: Before crushing after pre-screening (self-discharging iron separator) + return conveyor belt (magnetic drum) + if non-ferrous metals are present, an eddy current separator can be considered at the end. This forms a closed-loop removal system for ferrous metals.

Customer Case: A Large Mobile Crushing and Screening Unit Project

Background: The customer leased our company's tire-type mobile impact crusher + mobile screening station combination for operation at multiple construction waste disposal sites around the city.

Pain Points: Frequent site changes, significant material variations, strong randomness of metal contamination, poor single-point magnetic separation effect, and abnormal wear of impact crusher hammers.

Our System Solution:

First Stage: Install an ultra-strong magnetic suspended iron separator at the discharge point of the mobile feeder to the main conveyor belt to remove large surface and shallow metals.

Second Stage: At the head of the last conveyor before the material enters the impact crusher, replace the original roller with a permanent magnet strong magnetic head pulley to attract deeply buried metals.

Result: Forming a "crossfire network." The metal removal rate increased from approximately 70% to over 98%. The service life of the hammer mill was extended by 40%, and the customer was able to take on more projects during the 6-month lease period due to improved equipment reliability, resulting in a return on investment far exceeding expectations.

How to design and recommend a magnetic separation system for your production line?

Key Considerations for System Design

Material Flow Analysis: Draw a detailed process flow diagram to identify all possible metal intrusion points (feeding, transfer, circulating load).

Threat Assessment: Clearly define the most common types, sizes, weights, and magnetic properties of the metals.

Equipment Selection and Matching:

Suspended Magnetic Separator: Suitable for thick layers of material, easy to clean.

Magnetic Head Pulley: Used as a drive drum, ideal for removing the deepest embedded metals, providing the most thorough results.

Pipeline Magnetic Separator: Suitable for powdered materials conveyed pneumatically or in enclosed pipelines.

Our Recommendation Principles

We are not just equipment manufacturers, but also system solution providers. Our sales engineers will conduct on-site inspections or detailed analyses of your process flow to recommend different levels of system solutions, from "basic configuration" to "full protection configuration," ensuring that every penny of your investment is well spent.

Frequently Asked Questions about Magnetic Separation Systems (FAQ)

FAQ 1: Is a system much more expensive than a single magnetic separation device? Is the investment worthwhile?

Answer: The initial investment is indeed higher than a single device, but it should be considered from a total cost of ownership (TCO) perspective. A well-designed system can almost completely eliminate sudden damage to core components caused by metal. The cost of one major rotor or spindle repair is often enough to cover the entire system investment. The increased uptime, reduced maintenance costs, and improved product quality usually result in a return on investment in a short period, and the long-term value is enormous.

FAQ 2: Does the system require complex control and maintenance?

Answer: No complex control is needed. Standard magnetic separation systems operate independently, based on physical principles. Advanced options can integrate control, but it is not necessary. Maintenance is extremely simple: permanent magnet equipment is basically maintenance-free, requiring only regular cleaning of the adsorbed metal; self-discharging magnetic separators only require checking the discharge belt or mechanism. The maintenance requirements of the system are far less than those of the crushing equipment it protects.

FAQ 3: We already have a crushing line, is it difficult to add a system later?

Answer: It's not difficult; this is precisely our area of expertise. Our magnetic separation systems feature a highly modular design, allowing for customized design and installation based on the space, dimensions, and layout of your existing conveyor system. We provide a complete range of services, from on-site measurements and design to installation guidance, ensuring that the modification project minimizes disruption to your existing production.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!