River stone Properties

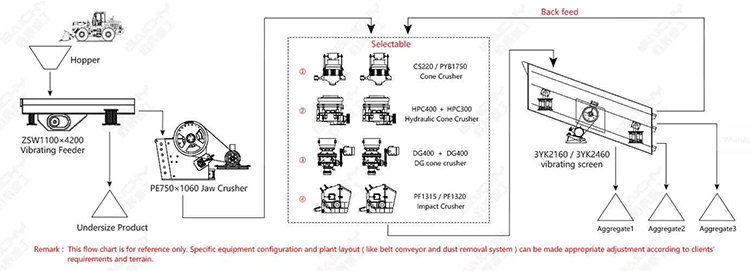

River stone crushing process

Recommended Core Equipment for River Pebble Crushing Process

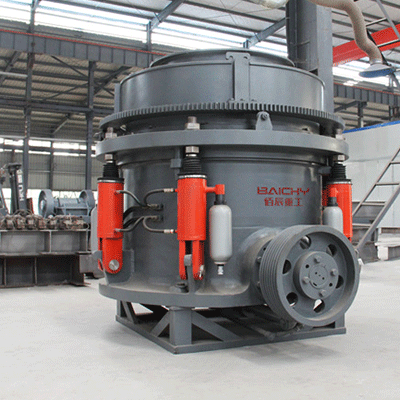

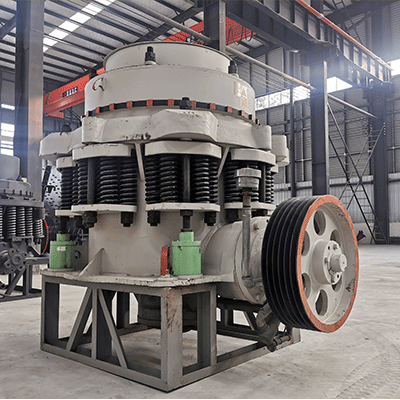

1. Cone Crusher (Preferred for Medium and Fine Crushing)

◦ Advantages: Employs the principle of interlayer crushing, achieving crushing through the mutual compression and grinding of particles. This principle results in less wear on the equipment, making it particularly suitable for processing high-hardness materials such as river pebbles. It offers stable operation, high efficiency, and good finished particle shape.

◦ Applicable Stages: Primarily used in the medium and fine crushing stages of the production line.

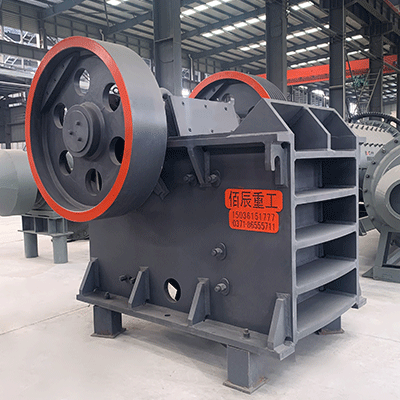

2. Jaw Crusher (Pioneer in Coarse Crushing)

◦ Advantages: Simple structure, reliable operation, and convenient maintenance. As the first stage of the production line, it easily handles the coarse crushing of large river pebbles, laying the foundation for subsequent crushing.

◦ Applicable Stages: Primary crushing (coarse crushing) in the production line.

3. Impact Crusher (Expert in Sand Making and Shaping)

◦ Advantages: Employs the "stone-on-stone" or "stone-on-iron" principle, combining crushing and shaping functions. The produced manufactured sand has a rounded shape and reasonable gradation, which can greatly improve the performance of concrete and mortar. It is the core equipment of a modern sand production line.

◦ Applicable Stage: The final stage of the crushing production line—sand shaping.

|

|

|

|

250-500 tph Stone crushing plant

How to Choose the Right River Pebble Crushing Equipment?

• Feed Size: The maximum size of the raw river pebbles.

• Capacity Requirements: The expected hourly output.

• Output Specifications: The required particle size range of the final product.

• Investment Budget: Including equipment purchase cost and long-term operation and maintenance costs.