Gypsum Powder Mill Manufacturer | Gypsum Grinding Equipment

As a manufacturer of mining crushing and grinding equipment with 20 years of experience, we understand that in the gypsum processing industry, choosing a high-efficiency, stable, and energy-saving gypsum powder mill is crucial to product quality and economic benefits. This article will provide an in-depth analysis of gypsum powder production equipment, offering comprehensive selection and application guidance.

Gypsum Powder Mill Overview: From Raw Material to Fine Powder

Gypsum, as an important industrial raw material and building material, owes its application value largely to the fineness, purity, and activity of its powder. The gypsum powder mill is the core equipment that completes this transformation. It is mainly used to crush, grind, and classify blocky or granular natural gypsum, desulfurized gypsum, or phosphogypsum, ultimately obtaining gypsum powder with different fineness requirements, providing high-quality raw materials for downstream products such as gypsum board, gypsum mortar, and mold plaster.

Basic Process Flow of Gypsum Powder Processing

Basic Process Flow of Gypsum Powder Processing

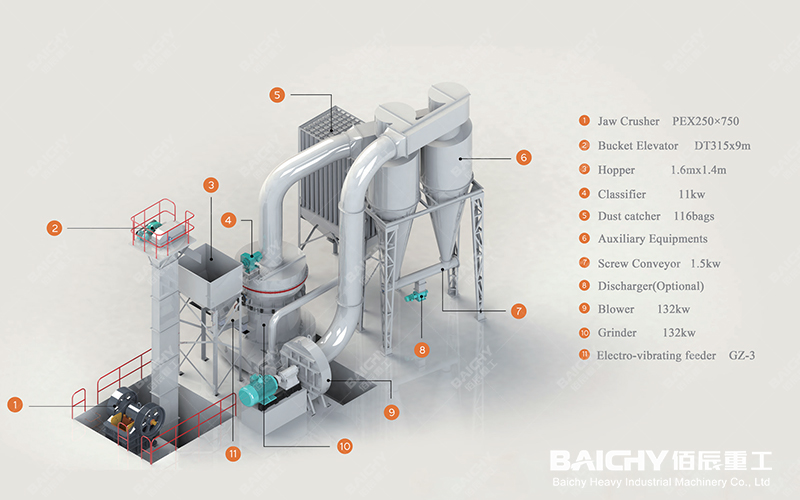

A typical gypsum powder production line usually includes the following key stages:

1. Crushing Stage: Jaw crushers or hammer crushers are used to crush large gypsum ore into smaller pieces (usually less than 30mm).

2. Grinding Stage: This is the core stage. Gypsum powder mills (such as Raymond mills, vertical mills, and ball mills) grind the small gypsum particles into powder.

3. Classification Stage: Qualified fine powder is separated using built-in or external classifiers, while coarse powder is returned for further grinding.

4. Calcination and Modification Stage: For building gypsum powder, the ground raw gypsum powder needs to be calcined to dehydrate and mature into gypsum. Some processes may involve drying or adding modifiers before or after grinding.

Significant Advantages of Specialized Gypsum Powder Grinding Equipment

Compared to general-purpose grinding mills, equipment specifically designed for gypsum powder processing offers advantages in efficiency, finished product quality, and operating costs.

1. High Efficiency and Energy Saving, Reducing Production Costs

Modern gypsum powder mills employ advanced grinding principles and structural designs. For example, vertical mills utilize bed grinding technology, resulting in 30%-50% lower energy consumption compared to traditional ball mills. An efficient grading system ensures that qualified fine powder is selected promptly, avoiding energy waste from over-grinding and directly reducing the production cost per ton of gypsum powder.

2. Stable Finished Product Quality and Adjustable Particle Size

Equipped with a precision powder classifier, the finished product fineness can be flexibly and stably adjusted between 80-600 mesh, with a concentrated particle size distribution, high product purity, and good activity. This is crucial for producing high-value-added specialty gypsum powder, ensuring consistent quality of downstream products.

3. High Degree of System Automation and Reliable Operation

Our equipment integrates an advanced electrical control system, enabling one-button start/stop, remote monitoring, and fault diagnosis. Key components of the main drive system use brand-name products, and the robust design of the entire machine allows for continuous and stable operation in mining environments, significantly reducing maintenance costs and downtime risks.

Grinding equipment customer site

Success Story Sharing: Helping Clients Build High-Efficiency Gypsum Powder Production Lines

We provided a complete 300,000-ton-per-year gypsum powder production line for a large building materials group in North China. The core of this line utilized our GRM series vertical gypsum mill.

• Client Challenges: The raw material was desulfurized gypsum with large moisture fluctuations, requiring stable product fineness (around 120 mesh) and energy consumption below industry standards.

• Solution: We configured an integrated solution of "crushing + drying + vertical mill grinding + calcination." The vertical mill integrates drying, grinding, and powder selection, efficiently processing materials containing moisture.

• Operational Results: Since its commissioning, the production line has operated smoothly, with a product qualification rate exceeding 99.5%. Power consumption was reduced by approximately 40% compared to their original production line, and the client recovered their equipment investment cost within two years. This fully demonstrates the significant value of choosing a professional gypsum powder mill and solution.

Equipment Selection Recommendations: How to Choose the Right Gypsum Powder Mill?

When selecting a gypsum powder mill, the characteristics of the raw materials, production capacity requirements, and finished product specifications must be comprehensively considered.

1. For small to medium production capacities (50,000-200,000 tons per year) and medium fineness requirements: Raymond mills are a classic and economical choice, with a simple system and low investment costs.

2. For large-scale production (over 200,000 tons per year), high-moisture raw materials, or requirements for high output and low energy consumption: Vertical roller mills are the best choice. They are highly integrated, have low energy consumption, and occupy a small area, making them the first choice for modern large-scale gypsum powder projects.

3. For ultra-high fineness (above 600 mesh) or gypsum powder with special physicochemical requirements: ultrafine vertical roller mills or air jet mills can be considered, but a comprehensive evaluation of energy consumption and cost is necessary.

As an experienced manufacturer of mining crushing and grinding equipment, we can provide you with free material testing and production line process design to ensure the most suitable gypsum powder processing solution for you.

Frequently Asked Questions (FAQ)

1. What are the key maintenance points for a gypsum powder mill?

A: Routine maintenance should focus on the wear of the grinding rollers and discs, the balance and wear of the classifier rotor, the wear of the fan blades, and the condition of the oil at all lubrication points. Regularly inspecting and replacing worn parts is crucial for ensuring long-term stable operation of the equipment and consistent product fineness.

2. What special considerations are needed when processing high-moisture raw materials (such as desulfurized gypsum)?

A: High-moisture raw materials easily lead to mill blockage, poor conveying, and reduced efficiency. Equipment with strong drying capabilities, such as a vertical mill, must be selected, or a dedicated dryer should be added before grinding. Simultaneously, the insulation and moisture-proof design of the entire system (especially the dust collector) is also critical.

3. How to control the final fineness of gypsum powder?

A: The fineness of gypsum powder is mainly achieved by adjusting the speed of the classifier (air separator) in the gypsum powder mill. The higher the speed, the finer the separated powder particles. Modern equipment is equipped with a convenient and easily adjustable frequency conversion control system, which can achieve stepless frequency adjustment within a certain range and precisely control the fineness of the finished product.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!