Crawler Mobile Jaw Crusher

In the world of mining, "good enough" often means lost profits and compromised efficiency. When operations shift to high-hardness, highly abrasive rock formations such as granite, basalt, and iron ore, the demands on crushing equipment escalate to a whole new level. This is where the Quarry-Grade Track Jaw Crusher comes in – it's not just an ordinary mobile crusher, but an ultimate solution specifically designed for demanding, continuous mining crushing operations, combining extreme durability, powerful performance, and intelligent mobility. As a professional manufacturer of mining mobile crushing equipment, we will reveal why it has become a core asset for modern, efficient mines.

Core Analysis: The Superior Architecture of the Quarry-Grade Track Jaw Crusher

The Quarry-Grade Track Jaw Crusher distinguishes itself from general-purpose models in its fundamental design. Every component, from the steel structure to the power system, is reinforced and optimized to withstand the extreme challenges of 24/7 continuous mining operations.

Reinforced Core Designed for Hard Rock

Heavy-duty Jaw Crusher Mainframe: Features a thicker frame, heavy-duty eccentric shaft, and large rolling bearings. Both the movable and fixed jaw plates use thickened manganese steel or custom alloy materials, ensuring a longer service life and higher crushing ratio when crushing high-hardness rocks.

Mining-Grade Track Chassis: Unlike ordinary tracks, it uses heavy-duty excavator or mining equipment-grade track assemblies, providing higher load capacity, stronger impact resistance, and more stable ground adhesion, allowing for safe movement in rough mining pits.

High-Power Power Pack: Equipped with a high-power diesel engine compliant with National III/Stage V emission standards, or a high-voltage motor option, providing continuous and stable power to ensure no power loss during full-load crushing.

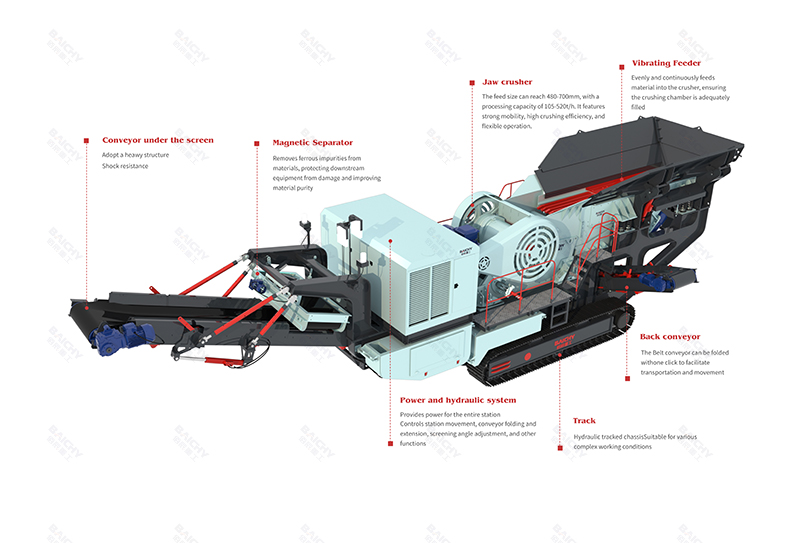

Heavy-duty Feeding and Pre-screening System: Integrates a heavy-duty vibrating feeder, and some models are equipped with a pre-screening function to separate soil and fine materials before entering the main crusher, reducing the load on the main crusher, improving the crushing efficiency of pure rock, and preventing blockages.

Five Strategic Advantages of Choosing a Mining-Grade Tracked Jaw Crusher

Investing in mining-grade equipment is essentially investing in higher uptime, lower cost per ton, and more flexible production planning.

1. Unparalleled Durability and Reliability

Core components are designed and selected according to mining conditions standards, significantly reducing unexpected downtime due to equipment failure. This means longer effective production time, directly translating into higher annual output and return on investment.

2. Higher Processing Capacity and Superior Product Particle Shape

The combination of powerful drive and optimized crushing chamber design not only efficiently processes high-hardness rocks but also produces primary aggregates with better particle shape and less flaky content, creating better conditions for downstream secondary crushing (such as cone crushers) and enhancing the market value of the final product.

3. Excellent In-Pit Mobility and On-Site Crushing

The equipment can move independently between different mining platforms or working faces within the mine pit, achieving on-site crushing that "follows the working face." This completely eliminates the high costs and safety hazards of traditional fixed crushing lines that rely on heavy trucks for long-distance in-mine transportation.

4. Rapid Configuration and Flexible Production Line Combinations

It can be used as an independent primary crushing unit or easily combined with equally mining-grade tracked mobile cone crushers and screening plants to form a fully mobile crushing and screening production line. This modular design allows mines to quickly adjust production layouts based on ore body changes and market demands.

5. Significantly Reduced Total Cost of Ownership (TCO)

Although the initial investment may be slightly higher, the total cost over its entire lifecycle is usually far lower than traditional solutions by saving significant in-mine transportation costs, reducing infrastructure investment, lowering maintenance costs, and improving overall production efficiency.

| Key Words |

Crawler-Type Mobile Crusher |

| Product Model |

Crawler Jaw Crusher |

| Capacity |

80-520t/h |

| Core Functions |

Tracked walking systems enable mobile operations |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Case Study: Efficiency Revolution in a Granite Mine

Case: Capacity Upgrade Project at a Large Granite Mine

This mine previously used a "excavator + truck transport to a fixed crushing station" model, resulting in high transportation costs and significant efficiency bottlenecks. After introducing a heavy-duty mining-grade tracked jaw crusher manufactured by our company, the equipment was directly deployed near the mining face. Large blocks of granite are simply fractured by a hydraulic hammer and then directly fed into a mobile crusher by an excavator. The crushed aggregate is then stockpiled by a mobile conveyor belt. This change reduced the need for truck transportation within the mine by more than 70%, increased overall production efficiency by over 35%, and recouped the equipment investment within one year.

Buying Guide: How to Choose True Mining-Grade Equipment?

When choosing, you should examine the following details like a mining engineer:

Structural component weight and material: Compare the weight of the main frame and the thickness of the plates of equipment of the same specifications. This is fundamental to durability.

Core component brand: Pay attention to whether bearings, hydraulic components, and motors/engines are from leading international brands. This is crucial for reliability.

Maintenance convenience design: Check whether lubrication points are easily accessible and whether jaw plate replacement is designed with hydraulic auxiliary tools. This directly affects daily maintenance efficiency and safety.

Manufacturer experience and support: Choose a manufacturer with a wealth of successful mining project cases and a global rapid response service network.

Frequently Asked Questions (FAQ)

Q1: What are the main differences between mining-grade crawler jaw crushers and ordinary crawler jaw crushers used for construction waste recycling?

A: The main differences lie in the design basis and component grade. Mining-grade equipment is reinforced for high-hardness, highly abrasive rocks and continuous high-intensity operation, such as heavier steel structures, more wear-resistant material science applications, larger cooling systems, and higher-specification powertrains. Construction waste recycling equipment focuses more on processing complex materials containing rebar and may emphasize specific functions such as iron removal.

Q2: Can it work stably in extremely cold mining environments or high-altitude areas?

A: True mining-grade equipment takes extreme working conditions into account. Cold start kits (such as fuel preheating, battery insulation), high-altitude engine options (power compensation), and antifreeze hydraulic oil and coolant solutions are available. When purchasing, you must clearly inform the manufacturer of the specific environmental parameters.

Q3: Will the cost of wear parts (such as jaw plates) be very high?

A: Although wear and tear on crushed hard rock is inevitable, mining-grade equipment controls costs through multiple design features: firstly, it uses more wear-resistant and thicker jaw plates, resulting in a longer lifespan; secondly, the symmetrical design allows the jaw plates to be reversed, maximizing material utilization; finally, some manufacturers offer wear part cost guarantees based on tonnage produced, making operating costs predictable and controllable.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!