Crawler Mobile Jaw Crusher

In mining, construction waste processing, and large-scale aggregate production projects, efficiency and mobility are often critical factors determining project success. While traditional fixed crushing production lines are stable, they are limited by site constraints, relocation costs, and complex infrastructure requirements. This is where the Concrete & Stone Crusher (Crawler Mobile Jaw Crusher) – the crawler mobile jaw crusher – becomes a revolutionary solution to these pain points. As a manufacturer of mobile crushing equipment for the mining industry, we will delve into how this core equipment is reshaping modern operating models.

Core Analysis: What is a Crawler Mobile Jaw Crusher?

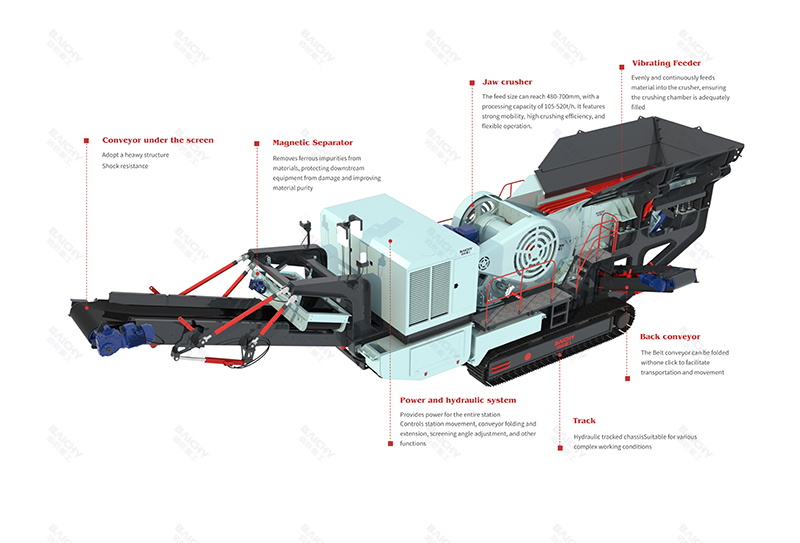

A crawler mobile jaw crusher is a self-propelled crushing and screening unit that integrates feeding, crushing, and conveying. Its core lies in using a robust and reliable jaw crusher as the main machine, mounted on a fully hydraulic-driven crawler chassis, giving it powerful crushing capabilities and excellent terrain adaptability.

Overview of Core Equipment Components

Jaw Crusher Main Machine: Responsible for primary crushing, using high-strength wear-resistant jaw plates, capable of powerfully crushing various rocks, concrete, and other materials with a compressive strength of no more than 320MPa.

Crawler Walking Chassis: Fully hydraulically driven, allowing the equipment to move freely in harsh mining and demolition sites, and even enabling remote control movement for flexible relocation.

Feeding System: Usually equipped with a vibrating feeder to evenly and continuously feed material to the main machine, preventing blockages and optimizing crushing efficiency.

Power System: Optional diesel engine or external power supply provides power to the entire machine, ensuring independent operation in remote areas without a power grid.

Conveying System: Crushed material is output through the main conveyor belt, and can be equipped with iron removers, screening modules, etc., as needed.

Why Choose a Crawler Mobile Jaw Crusher? Five Core Advantages

Compared to fixed or wheeled mobile crushing stations, the crawler mobile jaw crusher has unparalleled advantages in specific scenarios.

1. Unparalleled Site Adaptability and Mobility

The crawler design results in low ground pressure, allowing it to directly access raw material stockpiles, mining work faces, or construction waste disposal sites, and even operate stably on wet, soft, and uneven terrain. Eliminating the intermediate step of truck transportation of raw materials significantly reduces material transportation costs.

2. Rapid Deployment, Ready to Use Immediately

Upon arrival at the site, the equipment requires virtually no complex installation or infrastructure (such as concrete foundations). Simple leveling allows it to be put into production within half an hour. This means a leap in production efficiency for projects with tight deadlines and frequent site changes.

3. Integrated Design, Smart and Convenient Operation

Modern crawler-mounted mobile crushers utilize a PLC intelligent control system, enabling one-button start/stop, fault diagnosis, and remote monitoring. All equipment is highly integrated, reducing on-site connection work, and can be easily operated by a single person.

4. Crushing at the Source, Significantly Reducing Costs

The "where the material is, the equipment goes" model completely changes the traditional logic of "material being transported to the equipment," drastically reducing fuel costs and truck usage costs for raw material handling at the source.

5. Extremely Wide Range of Applications

It is not only suitable for mining limestone, granite, and other minerals, but is also the preferred equipment for concrete recycling and construction waste resource utilization. It can easily handle large amounts of reinforced concrete blocks generated after the demolition of buildings and bridges.

| Key Words |

Crawler-Type Mobile Crusher |

| Product Model |

Crawler Jaw Crusher |

| Capacity |

80-520t/h |

| Core Functions |

Tracked walking systems enable mobile operations |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Case Study: Successful Application of Crawler-Mounted Mobile Jaw Crusher

Case: A City's Construction Waste Resource Utilization Project

This project required processing over 500,000 tons of construction demolition waste. The client selected one of our large crawler-mounted mobile jaw crushers. The equipment was driven directly to the demolition site, crushing large reinforced concrete beams, columns, and walls into 0-100mm aggregates. Subsequently, these aggregates were used locally for road sub-base and brick making in the area. The entire process achieved "on-site crushing and local utilization," saving over 40% in transportation costs and creating considerable economic and environmental benefits.

How to Choose? Considerations for Relevant Equipment Recommendations

When choosing a crawler-mounted mobile jaw crusher, the following factors should be considered:

Material characteristics: Material hardness, size, and clay content determine the main machine model and wear part configuration.

Production requirements: Different models correspond to different processing capacities (e.g., 80-400 tons per hour). Discharge Particle Size: By adjusting the jaw crusher's discharge opening, different particle sizes of primary aggregate can be obtained.

Subsequent Process: Will it be used independently, or will it form a closed circuit with a mobile cone crusher and mobile screening plant? This determines whether more functional modules are needed.

Frequently Asked Questions (FAQ)

Q1: What are the main differences between a crawler-type mobile jaw crusher and a wheeled mobile crusher?

A: The biggest difference lies in mobility and stability. Crawler-type crushers use hydraulic-driven tracks for movement, offering excellent maneuverability, allowing them to climb slopes and adapt to complex terrain, but their travel speed is slow (usually <3km/h). Wheeled crushers are towed by a tractor, offering faster transfer speeds on flat ground, but require a higher degree of ground leveling and more support preparation.

Q2: Can it complete all crushing and screening work independently?

A: As a primary crushing equipment, it mainly completes the first crushing process. If multi-stage crushing (such as sand making) or precise classification is required, it usually needs to work in conjunction with a crawler-type mobile cone crusher, impact crusher, or mobile screening plant to form a mobile crushing and screening production line.

Q3: Is the equipment maintenance and upkeep complicated?

A: Modern equipment designs prioritize ease of maintenance. Core lubrication points are equipped with a centralized automatic lubrication system, and key components are easily accessible. Routine maintenance mainly involves checking the track tension, lubrication points, and wear of wear parts such as jaw plates, and performing regular maintenance according to the manual. Choosing a manufacturer that provides comprehensive after-sales service and technical support is crucial.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!