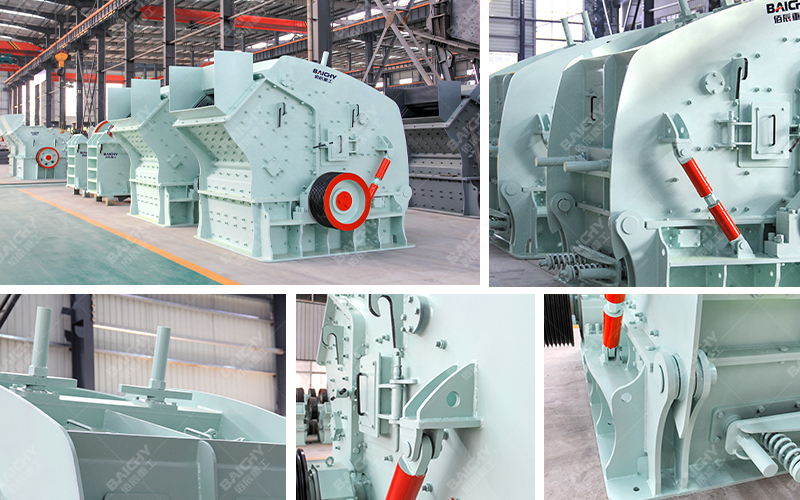

Introduction to PFW-1214 Impact Crusher

PFW-1214 impact crusher is an efficient medium and fine crushing equipment designed for crushing hard rocks (such as basalt and granite). It adopts heavy-duty rotor structure, high-chrome plate hammer and hydraulic cover opening device to ensure stable output when crushing high-hardness materials. It is especially suitable for stone processing that requires 3/4 inch (about 20mm) finished product particle size.

Why choose PFW-1214 to process 3/4 basalt stone?

Precise particle size control

• By adjusting the gap between the impact plate and the plate hammer, the discharge can be accurately controlled within the range of 3/4 inches, reducing over-crushing and improving the yield rate.

High capacity & low energy consumption

• When processing basalt, the output can reach 80-120 tons per hour (depending on the hardness of the material), the motor power is only 110-132kW, and the energy consumption is 30% lower than that of traditional jaw crushers.

Wear-resistant and durable design

• Key components (such as hammer and impact plate) are made of high-chromium alloy, which has a service life more than twice that of ordinary manganese steel and reduces maintenance costs.

Technical parameters and quotation sheet

| Parameter item | PFW-1214 specification |

| Rotor diameter × width | Φ1250×1400mm |

| Feed port size | 600×1400mm |

| Maximum feed size | ≤500mm |

| Finished product size range | 3/4 inch (adjustable) |

| Processing capacity | 80-120t/h (basalt) |

| Motor power |

Successful case: Basalt crushing production line

Customer background: Mexican building materials company, needs to process basalt into 3/4 inch aggregate for asphalt concrete.

Solution:

Equipment configuration: PFW-1214 impact crusher + 3YK2460 vibrating screen

Results:

Finished product qualification rate ≥ 95%

Comprehensive production cost reduced by 18%

FAQs

Q1: Can PFW-1214 crush the raw ore directly?

It is recommended to use a jaw crusher for coarse crushing (to ≤500mm) before entering the impact crusher to protect the plate hammer and improve efficiency.

Q2: Can the 3/4-inch finished product be used in a commercial concrete mixing station?

Absolutely, this particle size is a common standard for asphalt concrete and dry mortar.

Get your exclusive quote now

For a detailed quote or technical solution for the PFW-1214 impact crusher, please submit your request to:

Tel: 0086 15093222637

Email: [email protected] (Provide professional response within 2 hours)